2015 Full and Semi automatic glass cutting machine Laminated production Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic Glass Cutting Line

1. Company Information

1.Our company is one of the best professional company, with 12 years history, specialized in manufacturing insulating glass machine, glass cutting machine, pvc & aluminum window and door machine.

2.Since our company founded, "best quality, mutual benefit" is always our principle, offering the best equipment and technical support for the old and new customers.

3.Our products has been exported to many countries, such as Asian countries, European countries, Middle East area ,and South American countries.

Normal machine is properly adjusted before dispatch. You will be able to use the machines immediately.

You will be able to get free training advice towards glass cutting machine in our factory. You will also get free suggestion and consultation,

technical support and service by email/fax/tel and lifetime technical support.

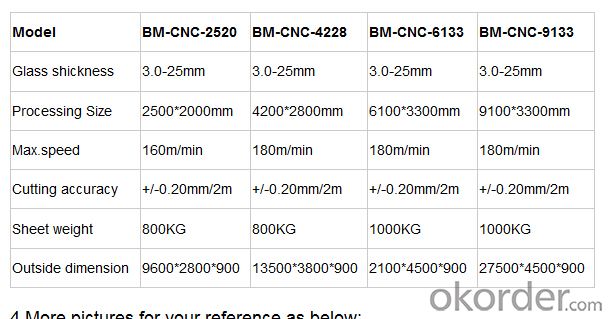

2. Technical parameter:

3. Features of our Machine Line

1). After starting the inputting machine, arms automatically suck glass from the shelf. Under sensor controlled, glass automatically find glass edge in the X and Y directions. After moving glass sheets to designated location, transport glass to the CNC cutting table. Under laser sensory element guidance, use laser-reader to get the position of the glass-sheet. Cutter will move to coordinate origin, and automatically start to cut according to the preinstall graph.

2). After cutting, glass will move to the Breaking Glass Table . Start break bars and to break the glass. At this point, the whole process work is completed.

4. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

Glass cutting line applies to: Building glass, insulated doors and windows, low-e glass, automobile glass, household appliance glass, furniture glass, solar energy glass, cook glass, mirrors, artwork glass and so forth.

5. Our Service for our customers

Payment Terms

♦ L/C, 30% deposit by T/T,70% spare payment L/C.

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union

Warranty Terms

All equipments is 12 months guarantee,lifetime maintance.

After Sale Service

Generally speaking,our Insulating Glass Processing Equipments need to install by our professional technician, Aluminum&UPVC Windows and Doors Processing Equipments does not need.

If buyers need to install by our technicians, the installation clause as follows:

INSTALLATION CHARGE

USD70/day for one worker for installation and training. Buyer supply hotel,food,ticket. Our technical worker need about 3-10 days for installation till all machines is good. When our worker finished all installation, buyer have to pay for installation charger to our worker according to $70 per day. Then our worker will teach your worker how to operate all machines correctly.

6. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q:Can organic glass be machined?

- Can be processed, acrylic plate processing with milling machine processing, no problem

- Q:Can the engraving process 2*2mm grooves on plexiglass plates?

- In addition the organic glass softening temperature is not high, only more than 100 point temperature. Try hot pressing.

- Q:The thickness of the epoxy glass cloth laminates by machining method for machining the thin board?

- The 2MM board will be on the five or six floor, huh?! However, this is what happened in those years, in the playing cards do not buy the age of stripping this to do their own playing cards, I do not know whether the situation is now glued to improve it, you can try. Reproduction of a variety of thickness of this kind of plate, and more is that you choose the right one, not on the line.

- Q:Status of glass machinery for glass machinery

- By the beginning of twentieth Century, there appeared the trend of following glass processing enterprises. Foshan, Shenzhen, Guangzhou, Shanghai, Hangzhou, Suzhou, Zhangjiagang and other relatively concentrated industrial areas have emerged. Its development area has expanded to the Shandong Peninsula to the Bohai rim area, and has spread to many cities in the mainland. At present, more than 50% of our country's glass cold processing equipments are manufactured in Guangdong and Shunde.By 2014, the development of glass machinery in China was highly dependent on the international market.

- Q:How much is the equipment for toughened glass production?

- Tempering furnace factory:Luoyang RandyLuoyang BeiboLuoyang specialShundeShunde LinThe domestic several well-known, including Soos to the small furnace well, special bending steel is more famous, Randy and the north is the furnace in recent years by Mount Taishan and the North Star, growth.

- Q:What are the equipment for making glass?

- Blowing glass bottle manufacturing and play trombone, but no matter what kind of glass production, could not be separated from the melt, clarification, molding, several stages of annealing equipment

- Q:Toughened glass production equipment and price

- Type 2436 (2440 * 3660) flat steel furnace is about 900 thousand or so, the prices of different manufacturers are different. Matching pretreatment equipment: 9, grinding machine linear machine 40 thousand or so;

- Q:Toughened glass machine more money?

- How large is the construction of this machine?! How many kinds of toughened glass machine do you need?! How many squares of glass can we produce in a day?

- Q:Can plexiglass be machined with CNC milling machines?

- Using CNC milling machines to make plexiglass is too wasteful.

- Q:Who knows how the glass is processed into fiberglass? How much is the approximate price of the equipment?

- The method of replacing platinum crucible is a widely used process at present. Its raw material is glass ball. "Tank" is currently the most advanced technology, the raw material powder is a mixture of "pyrophyllite based".

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2015 Full and Semi automatic glass cutting machine Laminated production Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products