2015 Full and Semi automatic glass cutting machine HOT SALE!

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic Glass Cutting Line

1. Company Information

1.Our company is one of the best professional company, with 12 years history, specialized in manufacturing insulating glass machine, glass cutting machine, pvc & aluminum window and door machine.

2.Since our company founded, "best quality, mutual benefit" is always our principle, offering the best equipment and technical support for the old and new customers.

3.Our products has been exported to many countries, such as Asian countries, European countries, Middle East area ,and South American countries.

Normal machine is properly adjusted before dispatch. You will be able to use the machines immediately.

You will be able to get free training advice towards glass cutting machine in our factory. You will also get free suggestion and consultation,

technical support and service by email/fax/tel and lifetime technical support.

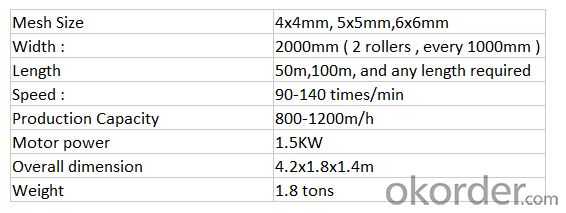

2. Technical parameter:

3. Features of our Machine Line

1.Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board,

gypsum board, bitumen etc)

2.Reinforced cement products.

3.Used for Granite, mosaic, marble back mesh etc.

4.Fabric waterproof membrane, asphalt roofing.

5.Framework material for einforced plastics, rubber products,.

6.Fire board.

7.Grinding wheel base fabric.

8.Road surface with geogrid

9.Construction caulking tape etc

4. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

Glass cutting line applies to: Building glass, insulated doors and windows, low-e glass, automobile glass, household appliance glass, furniture glass, solar energy glass, cook glass, mirrors, artwork glass and so forth.

5. Our Service for our customers

Payment Terms

♦ L/C, 30% deposit by T/T,70% spare payment L/C.

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union

Warranty Terms

All equipments is 12 months guarantee,lifetime maintance.

After Sale Service

Generally speaking,our Insulating Glass Processing Equipments need to install by our professional technician, Aluminum&UPVC Windows and Doors Processing Equipments does not need.

If buyers need to install by our technicians, the installation clause as follows:

INSTALLATION CHARGE

USD70/day for one worker for installation and training. Buyer supply hotel,food,ticket. Our technical worker need about 3-10 days for installation till all machines is good. When our worker finished all installation, buyer have to pay for installation charger to our worker according to $70 per day. Then our worker will teach your worker how to operate all machines correctly.

6. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q:Problems in the mechanical processing of glass fiber reinforced plastics

- I think it is of little significance to use cutting fluid when machining frp. Because the heat of cutting is not enough, air cooling can satisfy. But there will be an environmental problem - dust flying, which is harmful to people when they are sucked in. Therefore, we used to buy a set of industrial vacuum cleaners, processing machine parts (work stations) partially closed, operators with industrial masks, quite troublesome. Have also tried to dial a special machine (milling machine) to make glass fiber reinforced plastic products. With coolant, the chip separation mechanism is specially made, which is similar to the filter of grinding machine.

- Q:How much do you charge for a set of insulating glass processing equipment?

- Vertical divided into 1600 (1.6 meters), 1800 (1.8 meters), as well as the larger, insulating glass automatic production line, the price is roughly 23600

- Q:Do you use UV flatbed printers for glass processing?

- Do the glass door, glass tea table, glass printing etc., need to use UV flat-panel printers on the surface of the printed pattern.

- Q:How much would it cost to open a small toughened glass processing plant and need those equipment?

- It is also a lot of ground rent! There is purchase, at least 200 thousand of the original film ah, as well as the transformer for cheaper, of course with others is not the cost of electricity, but more expensive, there is a shelf, cable...... No 2 million doesn't work

- Q:What brand machines do you need to produce double glass? How much is the equipment? How much is the material? Can a large area do? Do you use artificial water for producing ordinary drinking glasses?

- Even if the ordinary double glass, but also to technical personnel, otherwise, glass is fragile, so scrap rate is very high. Technical staff will be much better.

- Q:Toughened glass production equipment and price

- 9 grinding head beveling machine more than 80 thousand; 19 thousand basic type profiled machines; drilling machine 18 thousand; washing machine price is unknown, specifications are type 2500, but also several class cleaning; normally want bilateral straight edge grinding machine, the price is unknown, probably need yiershiwan;

- Q:Where there is a machine for processing glass, that is, you can empty an empty wine bottle into a crystal, or a bead

- Without doing so, there can be no gains! The amount of grinding is too great, the products are not enough emery money, do not say money, wages, utilities, have to paste.

- Q:I would like to open a toughened glass processing plant, that is, buy ordinary glass back, and then processed steel, I would like to ask those equipment, how much money do I need?

- (1) consider the knowledge needed by the market economy, and make less money. When you become the market needs a certain aspect of the expert, wealth began to close to you.(two) when you want to be a boss, you'd better go to work, study technology, learn management, learn how to invest and manage money, and how to be a boss. You can't be a boss. You will continue to learn from experts, improve your own quality, and find more profitable jobs.

- Q:What kind of machinery and equipment do we need for the glass processing plant?

- Look what line you need to go, there are architectural engineering and Art Deco, and others, Art Deco, mainly carved machines, mosaics, sandblasting and painting.

- Q:What equipments are used in glass production?

- Cutting: Manual: rake ruler, hand knife machine cut: take piece + cutting machinePretreatment: horizontal drilling, vertical drilling, straight edge machine, double side grinding, water cuttingGlaze, tempered, laminated, hollow and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2015 Full and Semi automatic glass cutting machine HOT SALE!

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products