2015 Astm 1320, Aisi 4140 Alloy Steel Bar And Alloy Steel Rod

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

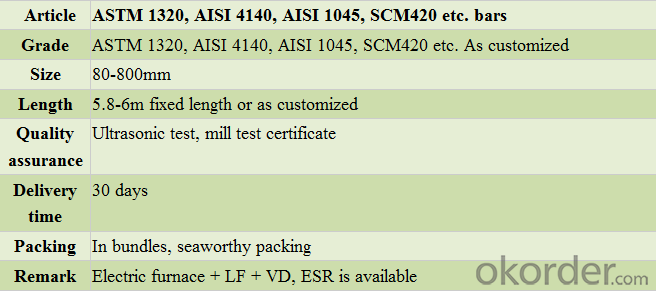

Item specifice

2015 Astm 1320, Aisi 4140 Alloy Steel Bar And Alloy Steel Rod

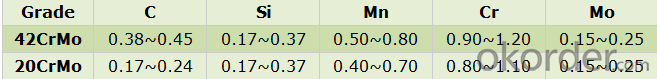

Product information

1. Produce Standard: GB, AISI, ASTM, SAE, EN, BS, DIN, JIS

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment: Normalized / Annealed / Quenched+Tempered

4. Quality assurance: All order we can received third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product detail

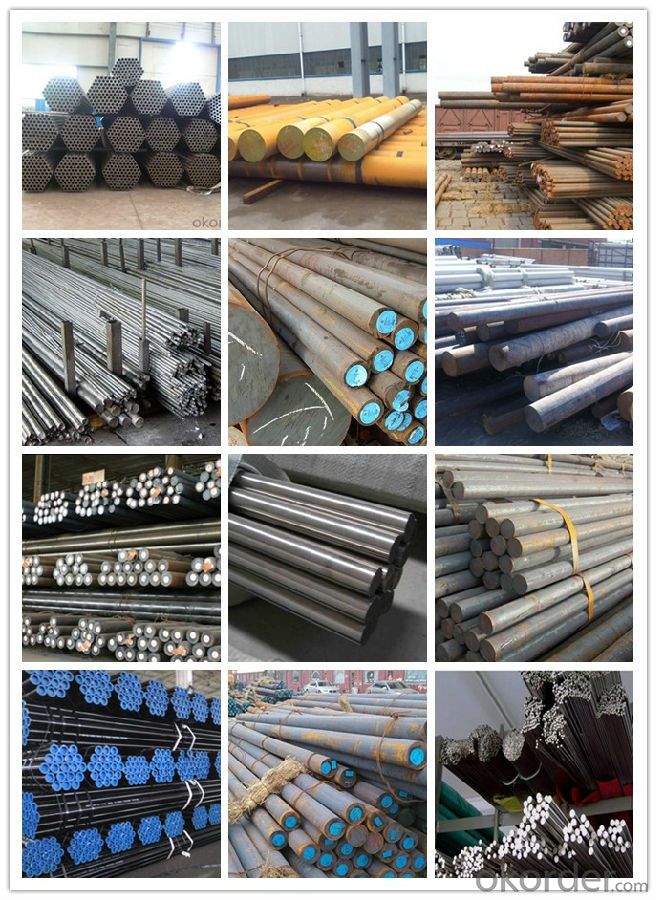

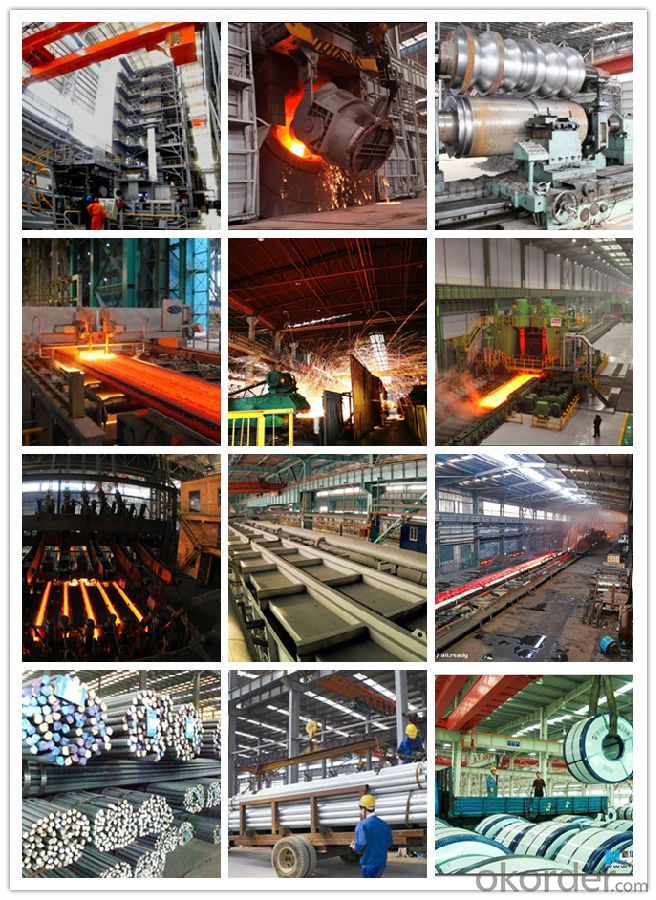

Product show

Work shop

Our Services

* Welcome to contact us with your detailed inquiry, you will be replied within 24 hours.

* You are promised to obtain the best quality, price and service.

* We'd like to provide samples for your confirm.

- Q:How is shock-resistant steel used in the production of impact tools?

- Shock-resistant steel is used in the production of impact tools to enhance their durability and resistance to breaking or chipping under high impact forces. This steel has been specifically designed to absorb and distribute the energy created by the impact, thereby preventing any damage or deformation to the tool. By using shock-resistant steel, impact tools can withstand heavy usage and deliver consistent performance, making them ideal for applications where repeated high-force impacts are involved, such as construction, automotive, or manufacturing industries.

- Q:What are the advantages of using special steel in specific applications?

- The advantages of using special steel in specific applications include its enhanced strength, durability, and resistance to corrosion. Special steel alloys are specifically developed to meet the unique requirements of various industries, such as aerospace, automotive, and construction. These alloys offer superior performance under extreme conditions, allowing for lighter and more efficient designs. Additionally, special steel can be heat-treated to further enhance its properties, making it ideal for applications that demand high strength and toughness.

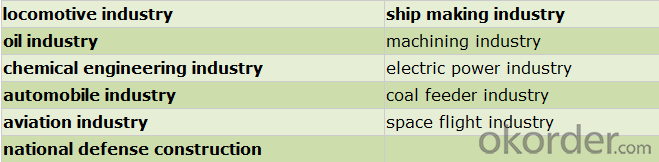

- Q:How does special steel contribute to the energy industry?

- Special steel plays a crucial role in the energy industry by providing high-performance materials that are essential for the construction and operation of various energy infrastructure. It is used in the manufacturing of turbines, generators, pipelines, and other components of power plants, helping to enhance their efficiency and reliability. Special steel's superior strength, corrosion resistance, and heat resistance properties make it suitable for withstanding the demanding conditions and extreme temperatures in power generation and transmission. Additionally, special steel is used in the production of renewable energy equipment such as wind turbines and solar panels, further contributing to the sustainable growth of the energy industry.

- Q:What are the safety benefits of using special steel?

- Using special steel can provide several safety benefits in various applications. One of the main advantages is its enhanced strength and durability compared to traditional steel. Special steel is often designed to withstand extreme conditions, such as high temperatures or corrosive environments, making it ideal for applications in industries like aerospace, automotive, and oil and gas. The high strength of special steel allows for the construction of safer and more reliable structures. It can withstand heavy loads, reducing the risk of structural failures or collapses. This is crucial in industries where the safety of workers, equipment, and the general public is of utmost importance. Another safety benefit of special steel is its resistance to corrosion. Corrosion can weaken structures and compromise their safety. Special steel is often alloyed with elements like chromium, nickel, or molybdenum, which provide excellent corrosion resistance. This makes it suitable for applications in marine environments, chemical processing plants, or any setting where exposure to moisture or chemicals is a concern. Special steel is also known for its ability to retain its mechanical properties at high temperatures. This makes it an excellent choice for applications where heat resistance is crucial, such as in the construction of fire-resistant structures or in the manufacturing of industrial ovens and furnaces. By using special steel in these applications, the risk of structural failure or fire-related accidents can be significantly reduced. Furthermore, special steel can offer improved fatigue resistance, which is important in applications subject to cyclic loading or vibration. Fatigue failure can occur when a material experiences repeated stress over time, leading to cracks and eventual failure. Special steel can be engineered to have excellent fatigue properties, reducing the likelihood of unexpected failures and improving the overall safety of structures or equipment. In summary, the safety benefits of using special steel include enhanced strength, durability, corrosion resistance, heat resistance, and fatigue resistance. These properties make special steel a reliable choice for industries where safety is a top priority, ensuring the protection of workers, equipment, and the general public.

- Q:What is the purpose of annealing in special steel production?

- The aim of annealing in the production of special steel is to enhance the mechanical characteristics and overall quality of the steel. Annealing involves subjecting the steel to a particular temperature and gradually cooling it, typically in a controlled setting. This procedure aids in relieving any internal stresses or strains that might have developed during previous manufacturing processes like rolling or forging. During the annealing process, the microstructure of the steel goes through changes, resulting in a more refined and uniform material. The process allows for the redistribution of atoms, thereby eliminating defects, improving grain structure, and enhancing the steel's toughness, ductility, and machinability. Furthermore, annealing helps in reducing the hardness of the steel, rendering it easier to work with and shape. It also enhances the steel's resistance to cracking and increases its ability to withstand corrosion and other environmental factors. In certain special steel alloys, annealing can also be employed to achieve desired physical properties such as increased hardness or improved magnetic characteristics. Ultimately, the objective of annealing in the production of special steel is to optimize the steel's properties and ensure it meets the specific requirements of its intended application, be it in industries such as automotive, aerospace, or manufacturing.

- Q:What are the applications of special steel in the power generation supply chain?

- Special steel plays a crucial role in the power generation supply chain, specifically in applications where high strength, corrosion resistance, and temperature resistance are required. It is extensively used in the construction of power plant components such as boilers, turbines, and generators, as well as transmission lines and distribution systems. Special steel ensures the reliability and efficiency of power generation equipment, enabling it to withstand harsh operating conditions and maintain long-term performance.

- Q:Can special steel be used in the plumbing industry?

- Yes, special steel can be used in the plumbing industry. Special steel, such as stainless steel or alloy steel, is often preferred for plumbing applications due to its corrosion resistance and high strength properties. It is commonly used for pipes, fittings, valves, and other components in plumbing systems to ensure durability and longevity.

- Q:How is mold steel used in injection molding?

- Mold steel is used in injection molding to create the molds or tooling that are used to produce plastic parts. It is a durable and heat-resistant material that can withstand the high temperatures and pressures involved in the injection molding process. The mold steel is shaped into the desired mold design and then used to form the plastic material into the desired shape through injection molding. This allows for the mass production of plastic parts with high accuracy and repeatability.

- Q:What are the quality control measures for special steel?

- Quality control measures for special steel involve several key steps and processes to ensure that the final product meets the required standards and specifications. These measures typically include: 1. Raw Material Inspection: Thoroughly checking the quality and composition of the raw materials used in the production of special steel, such as ensuring the correct chemical composition and metallurgical properties. 2. Process Control: Implementing strict controls and monitoring throughout the manufacturing process to ensure consistent quality, such as maintaining precise temperature control during heating and cooling processes, controlling the rolling or forging parameters, and ensuring proper heat treatment. 3. Testing and Sampling: Conducting various tests and sampling techniques to assess the quality of the special steel, including mechanical tests (such as tensile strength, hardness), non-destructive testing (like ultrasonic or magnetic particle inspection), and chemical analysis. 4. Dimensional and Surface Inspection: Verifying that the dimensions and surface finish of the special steel conform to the required specifications, such as measuring length, diameter, straightness, and checking for any defects or irregularities. 5. Final Inspection and Certification: Performing a final inspection to ensure that the special steel meets all quality standards and customer requirements. This may involve visual examination, additional testing, and issuing necessary certifications or quality assurance documents. By implementing these quality control measures, manufacturers can ensure the reliability, durability, and consistent performance of special steel, making it suitable for various critical applications in industries like automotive, aerospace, energy, and construction.

- Q:What are the main applications of special steel in the marine sector?

- Special steel is widely used in the marine sector for various applications. Some of the main applications include shipbuilding, offshore oil and gas exploration, and marine equipment manufacturing. Special steel is used to construct the hulls and superstructures of ships, as well as various components such as propellers, shafts, and rudders. Its high strength, durability, and corrosion resistance make it ideal for withstanding the harsh conditions of the marine environment. Additionally, special steel is also used in the construction of offshore platforms, pipelines, and underwater structures, as it can withstand extreme pressures and resist corrosion caused by saltwater.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2015 Astm 1320, Aisi 4140 Alloy Steel Bar And Alloy Steel Rod

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords