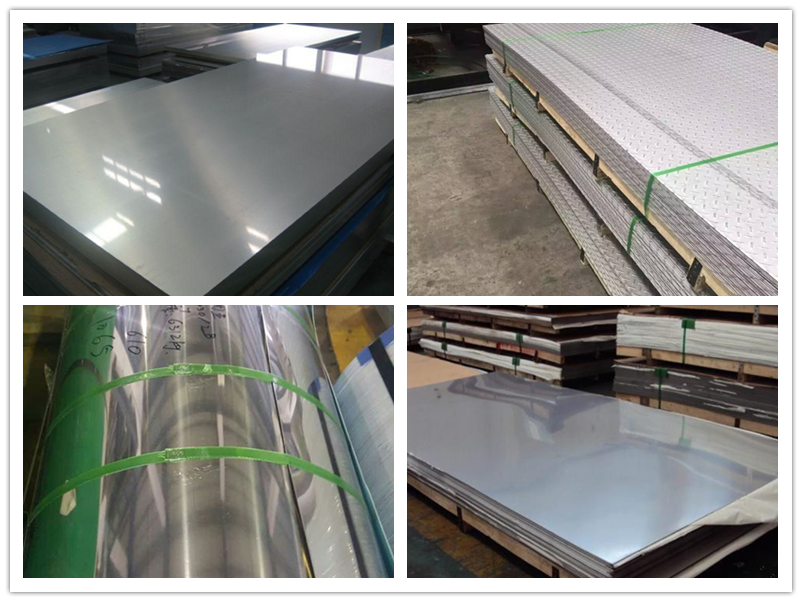

201 Stainless Steel Sheet 2mm hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

201 hot rolled stainless steel sheet 2mm

NAME | |

typ | Cold rolled;hot rolled |

thickness | 0.3-3mm;3mm-100mm |

Cold size | 1000mm*2000mm,1220mm*2440mm |

Hot size | 1500mm*6000mm |

Cold surface | 2B,BA,HL,8K,No.4,No.8 |

Hot surface | No.1 |

Material/Grade | 201,202,304,304L,321,316L,310S,317,4049L, etc. |

Standard | ASTMA240,ASTMA480,GB/T4237-1992,JIS |

Application | Auto or aircraft or construction industry,tableware,furniture , decoration for chemical equipment ,Industry purposes and building ornament, production manufacturing |

Place of Origin | Tianjin, China (Mainland) |

Brand Name | Tisco,Jisco,Baosteel,Lisco |

Technique | cold rolled ,hot rolled |

Certificate | ISO 9001:2008 |

Payment terms | T/T(recommended), L/c,western |

Leading time/Delivery Detail | Within 7-15 days after receipt of T/T or L/c at sight |

Packaging Detail | 1.with wooden pallets, or film covered, in the containers. 2.Export standard package or as the customers' demands. 3.seaworthy wooden cases, 4.with or without edge protector,steel hoop and seals, 5.export -ted standard package or as customers signal requirement |

Stock | Aways in stock |

Payment | 30% TT in advance, balance against copy B/L |

MOQ: | 1 TON |

Note

| We can produce other standard as the customers’ requirement

|

Producitivity | 10000Tons/Month |

1.We can supply you with reasonable and competitive price and good quality products. 2.If you are interested in any of products, please contact us for more information.

| |

Packaging & Shipping

Application

- Q:How do you prevent fingerprints or smudges on stainless steel sheets?

- To prevent fingerprints or smudges on stainless steel sheets, there are several effective measures you can take: 1. Clean with a microfiber cloth: Use a soft microfiber cloth to wipe down the stainless steel surface regularly. Microfiber is known for its ability to attract and trap dirt, dust, and oils without leaving streaks or smudges. 2. Use warm soapy water: Mix a small amount of mild dish soap with warm water and gently wipe the stainless steel surface with a soft cloth or sponge. Rinse thoroughly and dry with a clean towel. This method effectively removes grease, fingerprints, and smudges. 3. Invest in stainless steel cleaners: There are numerous stainless steel cleaning products available in the market. These cleaners are specifically formulated to remove fingerprints, smudges, and restore the shine of stainless steel surfaces. Follow the instructions on the product for best results. 4. Apply a protective coating: Consider using a stainless steel protective coating or sealant. These products create a thin, invisible barrier that helps repel fingerprints and smudges. Apply the coating according to the manufacturer's instructions and reapply as needed. 5. Avoid abrasive cleaners or tools: Abrasive cleaners, scrub brushes, steel wool, or harsh chemicals can damage the protective layer of stainless steel, making it more prone to fingerprints and smudges. Stick to non-abrasive cleaning methods and tools to maintain the integrity of the stainless steel surface. 6. Handle with care: When touching stainless steel sheets, try to handle them with clean hands or wear gloves to prevent the transfer of oils or dirt. Avoid dragging objects across the surface, as this can cause scratches and make it more susceptible to smudging. By incorporating these preventive measures into your cleaning routine and handling practices, you can effectively minimize fingerprints and smudges on your stainless steel sheets, keeping them looking clean and pristine.

- Q:What are the benefits of using patterned stainless steel sheets in interior design?

- Patterned stainless steel sheets offer several benefits in interior design. Firstly, they add visual interest and uniqueness to a space, allowing for creative and innovative design possibilities. The patterns can range from subtle to bold, providing options to suit various aesthetics and design themes. Additionally, stainless steel is a durable material that is resistant to corrosion, making it ideal for high-traffic areas or spaces prone to moisture. It is also easy to clean, making maintenance hassle-free. The reflective properties of stainless steel can also help to brighten a room and create an illusion of increased space. Furthermore, patterned stainless steel sheets are versatile and can be used in various applications, such as wall coverings, backsplashes, countertops, or even furniture accents. They can be used to enhance both modern and traditional interior designs, adding a touch of sophistication and elegance. Overall, the benefits of using patterned stainless steel sheets in interior design include their aesthetic appeal, durability, ease of maintenance, versatility, and ability to enhance the overall visual appeal of a space.

- Q:Can stainless steel sheets be used in food processing industry?

- Yes, stainless steel sheets can be used in the food processing industry. Stainless steel is a popular choice in this industry because it is resistant to corrosion, easy to clean, and does not react with food or beverages. It is also strong and durable, making it suitable for various applications such as food preparation surfaces, storage containers, and equipment. Additionally, stainless steel sheets have a smooth and non-porous surface, which helps prevent the growth of bacteria and ensures food safety. Overall, stainless steel sheets are a reliable and hygienic choice for use in the food processing industry.

- Q:Can stainless steel sheets be used for automotive applications?

- Yes, stainless steel sheets can be used for automotive applications. Stainless steel is a highly versatile and durable material that offers excellent resistance to corrosion, heat, and impact. These properties make it ideal for automotive applications where durability and resistance to harsh environments are essential. Stainless steel sheets can be used in various parts of the automotive industry, including body panels, exhaust systems, fuel tanks, and even interior components. Additionally, stainless steel can be easily formed, welded, and manipulated to meet specific design requirements, making it a popular choice in the automotive industry.

- Q:Can stainless steel sheets be used in food processing or medical applications?

- Stainless steel sheets have the capability to be utilized in food processing and medical applications. The reason behind its popularity in these industries is its outstanding resistance to corrosion, high durability, and effortless cleaning properties. The material is able to withstand chemical reactions, ensuring safety when it comes into contact with food and medical equipment. Commonly employed in food processing equipment, storage tanks, countertops, and surgical instruments, stainless steel sheets conform to the strict hygiene standards mandated in the food and medical sectors, thus establishing themselves as a dependable and fitting material for these applications.

- Q:Can stainless steel sheets be used for food processing equipment?

- Yes, stainless steel sheets can be used for food processing equipment. Stainless steel is a popular choice for equipment used in the food processing industry due to its excellent corrosion resistance, durability, and hygienic properties. It is resistant to staining, rust, and chemical damage, making it suitable for contact with food and cleaning agents. Stainless steel sheets are also easy to clean and maintain, reducing the risk of contamination. Additionally, stainless steel is non-reactive, meaning it does not interact with food or alter its taste, ensuring the safety and quality of processed food.

- Q:What is the elongation of stainless steel sheets?

- When stainless steel sheets are subjected to tensile forces, their ability to stretch or deform without breaking is known as elongation. This property is measured as a percentage of the original length of the sheet that can be stretched before it fractures. The elongation of stainless steel sheets can vary depending on the grade of stainless steel and the way it is manufactured. In general, stainless steel sheets have a higher elongation compared to metals like carbon steel because they are more ductile. However, the specific elongation value can vary based on factors such as the grade, thickness, and tempering of the stainless steel sheet.

- Q:What is the maximum width of stainless steel sheets available?

- The supplier and customer requirements can cause variations in the maximum width of stainless steel sheets. Typically, these sheets come in widths ranging from 36 inches (91.44 cm) to 72 inches (182.88 cm). However, certain specialty suppliers may have wider options, exceeding 96 inches (243.84 cm) or even more. It is crucial to consider that wider sheets might incur higher production expenses and longer delivery times. Therefore, customers should consult their supplier to ascertain the maximum width suitable for their particular demands.

- Q:What are the different types of stainless steel sheet surface finishes available?

- There are several different types of stainless steel sheet surface finishes available, each with its own unique characteristics and uses. Some of the most common types include: 1. No. 1 Finish: This is the most basic and commonly used finish, also known as hot rolled annealed and pickled (HRAP). It has a rough, dull appearance with visible grain lines and is typically used for industrial applications where aesthetics are not a major concern. 2. No. 2B Finish: This finish is achieved by cold rolling, heat treating, and pickling the stainless steel. It has a smooth, reflective surface with a moderate gloss and is commonly used for applications that require a clean, uniform appearance, such as kitchen appliances and architectural components. 3. No. 3 Finish: This finish is achieved by using progressively finer abrasives during the polishing process. It has a semi-polished, satin-like appearance with visible grain lines and is often used for decorative applications, such as furniture, signage, and automotive trim. 4. No. 4 Finish: This finish is similar to No. 3, but with a finer grain and higher gloss. It is achieved by using even finer abrasives during the polishing process and is commonly used for architectural and decorative applications that require a high-quality, mirror-like finish. 5. No. 8 Finish: Also known as a mirror finish, No. 8 is the highest-quality stainless steel sheet surface finish available. It is achieved by polishing the stainless steel to a highly reflective, mirror-like appearance. This finish is often used for high-end architectural and decorative applications where a premium, flawless finish is desired. In addition to these primary finishes, there are also specialized finishes available for specific applications. For example, a brushed finish creates a textured, brushed appearance by using abrasive belts or brushes against the stainless steel surface. Additionally, there are colored finishes that involve applying a thin layer of color to the stainless steel surface, providing a unique and eye-catching appearance. Overall, the choice of stainless steel sheet surface finish depends on the specific application and desired aesthetics, ranging from basic industrial finishes to high-end decorative finishes.

- Q:Can stainless steel plate spray paint?

- Topcoat. Because it is in the open, one hand paint with good weather resistance, on the other hand, it is very difficult to use paint, most of the prison film so that polyurethane paint is a two-component paint curing agent, without baking, the room temperature with the curing agent can be cured thoroughly. As the old brand is very good.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

201 Stainless Steel Sheet 2mm hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords