201, 202,301, 304, 316,304L,316L,309,410,430 Stainless Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

201, 202,301, 304, 316,304L,316L,309,410,430 Stainless Steel Coil

Thickness:0.1-120mm

Width:1000-2000mm

Length: As required

Typical physical properties for stainless steel coil

Grade | Chemical composition | ||||||

C | Si | Mn | P | S | Ni | Cr | |

% | % | % | % | % | % | % | |

309S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.04 | ≤0.030 | 12.00-15.00 | 22.00-24.00 |

Item | 201, 202,301, 304,316,304L,316L,309,410,430 Stainless Steel Coil |

Technical | Hot rolled and cold rolled |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,GB/T3280-2007,EN10095-99,JIS4312,etc |

Material | 201, 202,301, 304,316,304L,316L,309,410,430 |

Surface | NO.1,2B, mirror finish,4K,8K,Hairline finish |

Thickness | 0.1-120mm |

Width | 1000-2000mm |

Price term | FOB,CFR,CIF,CNF |

Application | Stainless steel coil applies to construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Stainless steel coil can be made according to the customer’s requirements. |

Contact | If you have any question, please feel free to contact me. |

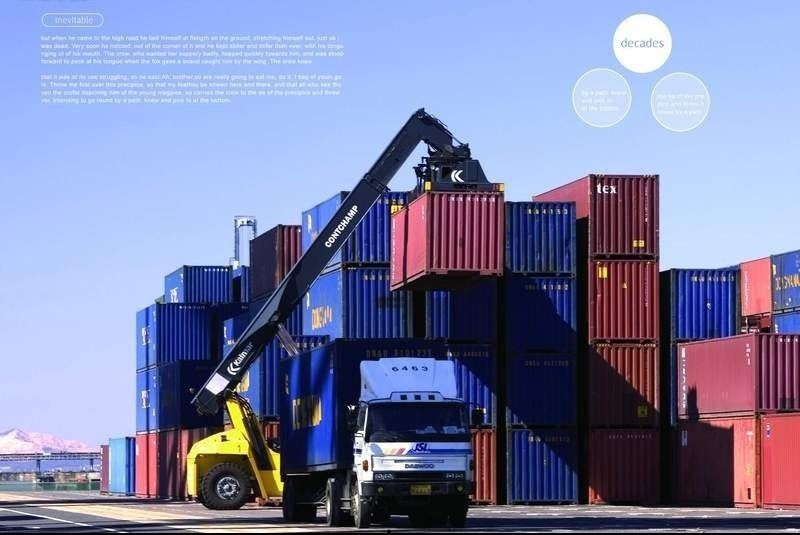

Packaging & shipping

Standard export seaworthy packing (with waterproof paper, metal belt pack sheet,

then put them in wooden pallet, then put in container) or customized.

Products are packed and labeled according to the regulations and customer's request.

Grate car is taken to avoid any damage which might otherwise be caused during storage

or transportation. In addition, clear labels are tagged on the otside of the packages

for easy identification of the product I.D. and quality information.

20 ft - GP: 5.8m (Length) * 2.13m (Width) * 2.18m (Hight) ------ About 23MTS

40 ft - GP: 11.8m (Length) * 2.13m (Width) * 2.18m (Hight) ------ About 27MTS

40 ft - HG: 11.8m (Length) * 2.13m (Width) * 2.72m (Hight) ------ About 27MTS

Production Machines

Application

Applications of Stainless Steel Coil:

1.Automotive: Automotive trim and molding/Difficult-to-form exhaust-system components, tubular manifolds, mufflers/Exhaust manifold and other exhaust-system components, catalytic converter shells, clamps

2. Construction: Gutters and downspouts, roofing, siding

3. Kitchenware: Cooking utensils, dishwashers, ovens, range hoods, refrigerators, skewers 4.Chemical processing: Oil refinery equipment, oil burner and heater parts

5. Appliances: Hot water tanks, residential furnaces

6. Power generation: Heat Exchanger tubing

7. Farming: Dry fertilizer spreaders/Farm animal pens

FAQ

why choose us?

1. All products are made of high-quality imported raw materials.

2. Our product passed SGS,BV,ISO certifications etc.

3. We are nominated as the AAA enterprise .

4. High corrosion resistant

5. Quickest and most efficient Response to Your Enquiry.

6..Stocked products and prompt delivery

7.Multiple payment terms

8.We offer competitive price(high quality)with best service

9.We have high technical production line

10.We have win high reputation based on best quality products

- Q:Can 111 stainless steel strips be coated or plated for added protection?

- Yes, 111 stainless steel strips can be coated or plated for added protection.

- Q:What are the factors affecting the strength of 111 stainless steel strips?

- The factors affecting the strength of 111 stainless steel strips include the composition of the steel, the manufacturing process, the temperature and time of heat treatment, the amount and distribution of impurities, the presence of strain hardening, and the thickness of the strips.

- Q:How do stainless steel strips handle exposure to chlorine?

- Stainless steel strips possess an exceptional ability to withstand corrosion and effectively endure chlorine exposure. Given that chlorine is an exceedingly reactive element capable of inducing corrosion in numerous metals, stainless steel sets itself apart by containing a substantial quantity of chromium. This chromium content enables the formation of a protective oxide layer on the surface of the stainless steel, acting as a formidable barrier that thwarts chlorine from accessing the underlying metal. Consequently, the stainless steel strip remains shielded from corrosion. Furthermore, stainless steel boasts the presence of additional alloying elements such as nickel and molybdenum, which further bolster its corrosion resistance in chlorine-rich surroundings. All in all, stainless steel strips emerge as an outstanding choice for applications involving chlorine exposure, as they retain their strength and integrity even in the harshest conditions.

- Q:Can stainless steel strips be used in food storage containers?

- Yes, stainless steel strips can be used in food storage containers. Stainless steel is a non-reactive and durable material that does not leach harmful chemicals into food, making it safe for storing various types of food. Additionally, stainless steel is resistant to corrosion, easy to clean, and does not retain odors or flavors from previous stored items, making it an excellent choice for food storage containers.

- Q:Can stainless steel strips be used in the wastewater treatment industry?

- Stainless steel strips have proven to be highly valuable in the wastewater treatment sector. Renowned for their resistance to corrosion, durability, and strength, stainless steel is an ideal material for a wide range of applications within wastewater treatment plants. These strips are frequently employed in the construction of tanks, pipelines, and other equipment that come into contact with wastewater. Within wastewater treatment plants, stainless steel strips are commonly utilized in the fabrication of screens, filters, and sieves. These essential components are crucial for effectively eliminating solid particles, debris, and other impurities from the wastewater. Due to their resistance to corrosion caused by the harsh chemicals and contaminants found in wastewater, stainless steel strips ensure the longevity and optimal performance of these components. Moreover, stainless steel strips are also employed in the construction of pumps, valves, and fittings within wastewater treatment plants. These components must endure high pressure, aggressive chemicals, and continuous exposure to wastewater. The remarkable mechanical properties of stainless steel, such as its high tensile strength and erosion resistance, make it an excellent choice for these demanding applications. Additionally, stainless steel is hygienic and easy to clean, which is of utmost importance in the wastewater treatment industry to prevent the growth and accumulation of harmful bacteria and microorganisms. Stainless steel strips can be effortlessly maintained, minimizing the risk of contamination and ensuring the efficiency of the treatment process. Overall, stainless steel strips are a dependable and long-lasting material for use in the wastewater treatment industry. Their outstanding corrosion resistance, strength, and hygienic properties make them suitable for a wide range of applications within wastewater treatment plants.

- Q:Are 111 stainless steel strips suitable for cryogenic storage tanks?

- Yes, 111 stainless steel strips are suitable for cryogenic storage tanks. 111 stainless steel is a type of austenitic stainless steel that offers excellent corrosion resistance, high strength, and good toughness, making it an ideal choice for cryogenic applications. It can withstand extremely low temperatures without becoming brittle or losing its mechanical properties. Additionally, 111 stainless steel has good weldability and formability, making it easier to fabricate into the required shape for cryogenic storage tanks. Overall, 111 stainless steel strips are a reliable and durable material for cryogenic storage tanks, ensuring the safe and efficient storage of cryogenic liquids or gases.

- Q:What are the common tests performed on stainless steel strips?

- There are several common tests performed on stainless steel strips to ensure their quality and suitability for various applications. Some of these tests include: 1. Chemical Composition Analysis: This test determines the elemental composition of the stainless steel strip, including the percentage of various alloying elements such as chromium, nickel, and molybdenum. It helps verify if the material meets the required specifications and standards. 2. Mechanical Properties Testing: This involves evaluating the mechanical characteristics of the stainless steel strip, including its tensile strength, yield strength, elongation, and hardness. These properties are crucial in determining the material's strength and durability. 3. Corrosion Resistance Testing: Stainless steel is known for its excellent corrosion resistance. Tests such as salt spray testing, pitting corrosion testing, and intergranular corrosion testing assess the strip's resistance against various corrosive environments. These tests ensure that the stainless steel strip will perform well in its intended application. 4. Surface Finish Analysis: This test examines the surface quality of the stainless steel strip, including the presence of any defects, scratches, or blemishes. It ensures that the surface finish meets the required standards and provides the desired aesthetic appearance. 5. Dimensional Inspection: This test verifies the dimensional accuracy and tolerances of the stainless steel strip. It ensures that the strip's width, thickness, and length meet the specified requirements. 6. Microstructure Examination: This test involves analyzing the microstructure of the stainless steel strip using techniques like metallography and microscopy. It helps identify any potential defects or abnormalities that may affect the material's performance. These tests are essential in ensuring the quality, reliability, and performance of stainless steel strips in various industries, including automotive, construction, and manufacturing. By conducting these tests, manufacturers can deliver stainless steel strips that meet the highest standards and customer expectations.

- Q:How do stainless steel strips compare to aluminum strips in terms of strength?

- Stainless steel strips are generally stronger than aluminum strips.

- Q:What is the maximum temperature resistance of stainless steel strips?

- The specific grade of stainless steel used greatly affects the maximum temperature resistance of stainless steel strips. Generally, stainless steel exhibits excellent heat resistance properties and can endure high temperatures without significant deformation or loss of strength. Typically, standard stainless steel grades like 304 and 316 can withstand temperatures up to 1500°F (815°C) without major issues. However, certain specialized stainless steel grades, such as 310 and 330, offer even higher temperature resistance, reaching up to 2100°F (1150°C) and 2200°F (1200°C) respectively. Additionally, it is important to consider factors like exposure time, corrosive agents, and the specific application, as they can also influence the maximum temperature resistance of stainless steel. Therefore, it is advisable to consult the manufacturer or a material specialist to determine the maximum temperature resistance of stainless steel strips for a specific application or environment.

- Q:What are the dimensions and thickness ranges available in 111 stainless steel strips?

- The dimensions and thickness ranges available in 111 stainless steel strips can vary depending on the manufacturer and supplier. It is advisable to check with the specific manufacturer or supplier for the exact dimensions and thickness ranges they offer.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

201, 202,301, 304, 316,304L,316L,309,410,430 Stainless Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords