20 inch cast iron manhole cover for Industry and Mining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

Material: Cast(Grey) Iron (GG 20, GG 25) and Ductile(SG) Iron(GGG 50).

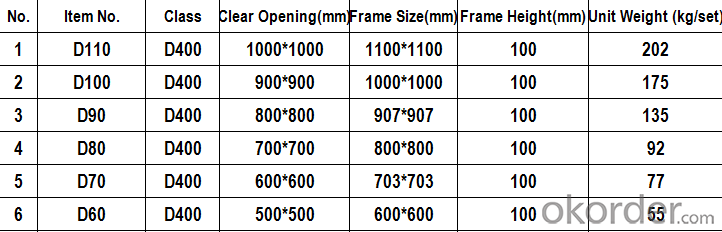

Sizes: 300 mm X 300 mm (11.81" X 11.81") clear opening to 1200 mm X 1200 mm (47.2" X 47.2") clear opening.

Load Rating: A15, B125, C250, D400, E600 and F900

Painting: Black Bitumen, Epoxy and other paint as per provided by customers.

Other Features: Hinging, Locking provision available, Leak proof and customized designed available.

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than.

Contain no metal and no recovery value, anti-theft.

Specifications

Packaging and Shipping

Delivery Detail: 8 days if your order is 20"container

Packaging: Details Pallet with bubble film, Carton or with pallet

Pictures

Company Information

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all

over the world.

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Professional technical support with free charge.

5. After the cooperation: Any of your problem will be solved within 24 hours.

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your requirement, but it maybe let your purchasing cost changed also.

3. Could you specially design and produce for clients?

A: Of course, we have all kinds of professional engineers. We can design and produce special products according to customers' requirements. Such as: special size, special control, OEM, etc.

- Q:Why do casting parts have air holes?

- Cangshan Qiao hidden his answer is quite comprehensive, you can try using inert gas to reduce air cover

- Q:What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- Corundum sand: the main mineral composition is corundum alpha -Al2O3, used for investment casting, ceramic mold casting shell materials. The olivine sand: the main mineral composition of olivine (MgFe) 2SiO4, used in cast iron, non-ferrous alloy castings and high manganese steel casting molding sand and the core sand. Silica resources in nature resources, but suitable for casting with high SiO2 content of natural silica sand is not too much. Since 1951, China has carried out a general survey of the casting sand resources in the territory, but mainly limited to the main traffic lines and major industrial cities. Survey results show that Chinese can be used for natural silica sand casting is very rich in resources, a wide range of distribution. Inner Mongolia Zhelimumeng, natural silica sand reserves amounted to hundreds of millions of tons, the particle shape close to the circular, the content of SiO2 is about 90%. Fujian, Jinjiang Dongshan sea sand, the content of SiO2 is 94 to 98%, with a low volume of mud, are good natural silica sand. Are Duchang, Yongxiu Jiangxi County Xingzi, a large number of Quaternary lacustrine deposition of silica sand, the content of SiO2 is about 90%, low iron content, alkaline oxide less, uniform size, is a good lake sand. Guangzhou, Hunan and other places have abundant easily broken weathered sandstone, processing artificial silica sand, the content of SiO2 in more than 96%, can be used for the production of steel castings. Jiangsu Nanjing red sand, sandy mud pure, moderate, strong permeability, good viscosity, high silica content, less water, fine particles, pulls out the casting is smooth, stable quality, can be made of cast iron and non-ferrous metal parts of the sand and core sand

- Q:How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q:What is the casting material?

- Gray iron, carbon steel, low alloy steel, ductile iron, stainless steel, Aluminum Alloy can all be cast out

- Q:What is the difference between casting and stamping parts?

- The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning and rectification are several main stamping processes. The difference between stamping parts and castings: with thin, uniform, light, strong features, stamping can be produced by other methods difficult to make, with stiffeners, ribs, UPS or flanging of the workpiece, to improve its rigidity. Due to the use of precision molds, the workpiece accuracy up to microns, and repeated high precision, specifications consistent, you can punch out of the hole, lug and so on.

- Q:In theory, which is more expensive, forging parts or casting parts?

- The structure of the casting is relatively flexible in design, and the modeling is easy to realize.

- Q:Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q:Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- Casting, do not need to provide a rough casting foundry drawings, according to your chart will put foot margin in the processing needs of the surface, the rest of the size can be found according to the mechanical design manual and manual casting.

- Q:Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- The tolerance of a specific size can be obtained from the tolerance grade and nominal size of the casting.

- Q:Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 3, the resonance method is cast on its resonant frequency vibration 1060ndn, to eliminate the residual stress in casting.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

20 inch cast iron manhole cover for Industry and Mining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products