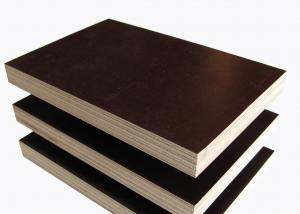

18mm film faced plywood,Mr/melamine WBP glue film faced plywood,poplar core/hardwood core shuttering plywood for construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

uick Details

| Type: | Place of Origin: | Brand Name: | |||

| Model Number: | Usage: | Grade: | |||

| Main Material: | Formaldehyde Emission Standards: | Plywood Type: | |||

| Size: | Thickness: | Core: | |||

| Color of film: | Tensile adhesion: | Bending Strength: | |||

| Compressive Strengt: | Compressive Strength: | Warp: |

Packaging & Delivery

| Packaging Detail: | Inner packing: inside pallet is covered with 0.2mm plastic bag Outer packing: by pallet, wrapped in carton, reinforced with iron belt |

| Delivery Detail: | 15Days |

Specifications

film faced plywood

1 waterproof

2 UV capability not easily fade

3 Anti-scratch, anti-acid alkali

4 Environmentally, E1 gra

610*2500*20mm film faced plywood manufacturers,marine plywood

Specifications

1. More than 12 years production experience

2. More than 8 years export experience

3. Excellent after-sell service

1. Big Size: The biggest size is 2440*1220mm, 915*1830 mm, which could decrease the numbers of the joint and increase the working efficiency. And the planking will not deform and crack, it can resist water well, re-use many times and demoulds easily.

2. Light weight: It is more suitable for high-rise building and bridge construction.

3. Re-use number: For Melamine glue, usually can be used about 8 times, and for WBP glue, can be re-using above 15 times.

4. Concrete building: It can keep the surface smooth and beautiful when used for pouring, and you don’t need to plaster the wall for second time, for it can decorate directly that will decrease the construction period by 30%.

5. Corrosion resistance: It will not pollute the surface of the concrete.

6. Good moisture-retention: It is good for construction, and in winter it can be used as template for curved surface.

7. Good workability: It is better than bamboo plywood and small steel plywood in terms of nailing, sawing and drilling, it can be processed to template with all shapes according to needs.

Product advertage:

1.The transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2.It is good to keep surface warm so in winter the project can also be continued.

3.After installation of concrete, the surface looks like a mirror. (The cement does not stick.)

4. The film faced plywood can be used to make camber and it also can be cut into small pieces according the special requirements.

5.Environmentally friendly.

6.It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

- Q:What is the difference between plywood glue E0E1?

- Melamine gel: moisture-proof, and has a certain resistance to boiling, weather resistance / can be used for outdoor or indoor, but can not often be water immersion.

- Q:How to use building plywood?

- Four types of plywood for the tide resistant plywood, used in the indoor normal, general purpose plywood with beech, linden wood, ash, birch, elm, poplar and so on.

- Q:What does plywood mean and its synthesis?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides.

- Q:Class III resistant tide plywood class IV tonic resistant plywood

- Mild wood veneer: with Ash, willow wood, color wood, birch and other peeling into 0.1-0.5mm thick sheet, plywood as a substrate made of glued, its beautiful pattern, good decorative

- Q:Plywood quality requirements include appearance level, size, physical and mechanical properties of the three elements.

- Thickness from 4mm below the thin plywood. 3mm, 3.5mm, 4mm thick plywood for common specifications

- Q:Now what is the market for plywood development?

- has also been greatly improved in the international market more and more competitive. China is not only a large veneer export, or the world's largest plywood producer.

- Q:Multilayer board, also known as three plywood and plywood

- the plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

- Q:What is the type of plywood editing?

- the plywood is divided into decorative plywood (for the surface needs to paint transparent paint Furniture, sewing machines and all kinds of electrical appliances and other products)

- Q:Multilayer plywood with what method is fixed

- Plywood is one of the common materials for furniture, one of the three panels of man-made board, but also for aircraft, ships, trains, cars, construction and packaging materials

- Q:Now the market prospects for plywood

- regulate export order. With the expansion of China's infrastructure construction and the strengthening of the development of the Midwest, plywood market has great potential.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

18mm film faced plywood,Mr/melamine WBP glue film faced plywood,poplar core/hardwood core shuttering plywood for construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords