12mmE2 Grade Density Board Floor Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description

The density board is also called the fiber board, which is made of wood fiber or other plant fiber as raw material, urea formaldehyde resin or other suitable adhesive. According to the different density, it is divided into high density board, medium density board and low density board.

MDF as soft impact resistance, easy processing, abroad is a good material for making furniture

2.Product Characteristic

1, MDF is very easy to finish processing. All kinds of paint, paint can be evenly coated on the density board, is the first choice for the effect of paint.

2, density board is a beautiful decorative plate.

3, all kinds of veneer, tape film, decorative panels, light metal sheet, melamine board materials can be glued to the surface of the density board.

4, the hard density board through the punching, drilling, but also can be made into a sound absorption plate, used in the construction of the decoration works.

5, the physical performance is excellent, the material is uniform, there is no dehydration.

3.Parameter

Class: I

Moisture content: less than 12%

Apparent density: 830

Bending strength: more than 17.2MPa

Special features: not easy to split

Specifications: 12mm*1260mm*2470mm

Purpose: floor base material

Product Code: dndfyd12SE2-830

Product specifications: 12*1260*2470mm

Production line: imported 4 feet continuous flat pressure

Mill: Andrea F

Material: poplar wood

Color: light color wood color

Environmental protection grade / glue: E2

Density: 830 fand kg/m

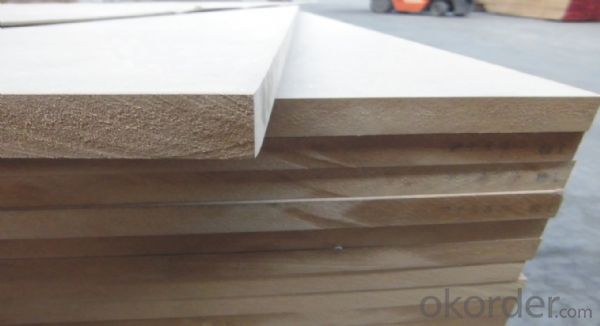

4.Reference Picture

- Q:Wood preservatives

- 5, transport wood products are leaching and storage warehouse moist with mold survival conditions. When there is suitable for mold survival of nutrients, water and temperature conditions, woody mildew rot will occur. More anti-mildew measures and methods can enter Baidu space.

- Q:How do I bleach wood products?

- then add 50 grams of bleaching powder, with this solution brush the surface of wood, to be bleached with 2% soapy water or dilute hydrochloric acid solution clear...

- Q:How does the wood bleach?

- Hydrogen peroxide, also known as hydrogen peroxide, which is the application of more bleaching effect of a better bleach. Commonly used concentration of 15-30%, it will be applied to the surface of the wood can release a strong force of oxygen, decomposition of wood pigment, so that white, in order to accelerate the release of oxygen, hydrogen peroxide can be mixed with ammonia, with this Bleaching agent wet the surface of the wood, after ten minutes, with cold water to bleach off on it. Ammonia can not be added too much, under normal circumstances, 25% of the amount of ammonia added about 5-10% of hydrogen peroxide.

- Q:What is the flame retardant principle of wood flame retardants?

- 2 wood flame retardant components of boric acid and GUP acid decomposition products catalyzed wood dehydration, degradation, and wood pyrolysis products of condensation, polymerization, aromatization and other reactions, can change the way of wood pyrolysis and make it conducive to The direction of carbonization, wood flame retardant significantly catalytic role in the charcoal, so that the combustion of wood burning heat greatly reduced, which is the main aspects of wood flame retardant flame retardant mechanism; more wood knowledge and information in the wood sector number.

- Q:Water content is too high or too low, will cause the quality of wood in the home improvement

- In order to keep the moisture content of wood solid, you should pay attention to the decoration in the following points

- Q:How to avoid deformation of wood products

- But the two materials of wood products contain a certain amount of water. Most of the consumers think that the more dry the better wood, it is this view of biased biased. The moisture content of wood only in the category of deformity to maintain a solid, easy to protect the decoration does not show quality problems. In the home improvement in the application of wood and wood materials, the water content should be about 8% of the general is appropriate. Water content is too high or too low, will result in the production of wood to do the quality of the problem. Home decoration are inseparable from the extensive use of wood products, such as curtains, heating hood, fixed furniture, wood lines and sets and so on. However, once the room temperature and humidity changes, and some wood products will be cracking, warping and deformation and other issues. In fact, many of the quality of home decoration problems, are out of the moisture content of wood products. Whether it is still wood materials are man-made sheet, all the wood products contain a certain amount of water. Many consumers think that the more dry the better wood, in fact, this view is biased. The moisture content of wood only in the deformity scale to maintain stability, the ability to protect the decoration does not emerge quality problems. In the home improvement of wood and wood materials, the water content of the normal should be about 8% is appropriate. Water content is too high or too low, will cause the quality of wood in the home improvement.

- Q:Wood furniture products which processes need constant temperature and humidity?

- 1, wood drying kiln or wood drying room: there are dry wood raw materials; 2, wood health room or called wood health library: for the semi-finished wood products and temporary storage of health; 3, wood balance or wood balance room: for wood semi-finished products or finished goods before the balance of dry;

- Q:How to use wood products paint

- 1. varnish, with a transparent putty block hole, and then covered with a transparent putty, grinding process found uneven, to be leveling treatment (scraping putty polished), after the basic formation of the primer if it is pine first to do a closed , After the first primer to do the leveling process (and then choose whether to do the second primer) and then make the paint twice in general.

- Q:Those stocks are the main wood products

- Coronal Wood Industry: Branch of the wood industry plans to build timber processing projects, the main supply of the company's current production of solid wood flooring core wood, table and three solid wood composite floor semi-finished products, multi-layer parquet semi-finished products. Mulan factory wood processing capacity of the initial design: annual production of 20,000 square meters (can supply an annual output of 1.5 million square meters of solid wood flooring production); with an annual output of 1.5 million square meters table; with an annual output of 1.5 million solid wood composite floor Square meters. The project is scheduled to be completed in the first half of 2008 and will be commissioned in the second half of 2008.

- Q:How to prevent wood from "dehydrating"?

- Once the room temperature and humidity changes, some wood products will be cracking, warping and deformation and other issues. Most of these quality problems are in the moisture content of wood products. Whether it is solid wood or man-made sheet, all the wood products contain a certain amount of water. Many consumers think that the more dry the better wood, in fact, this view is biased. Wood moisture content only in the normal range to maintain stability, in order to ensure that the decoration does not appear quality problems. General household use of wood materials, moisture content should be about 8% is appropriate. Water content is too high or too low, will cause the quality of wood in the home improvement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

12mmE2 Grade Density Board Floor Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products