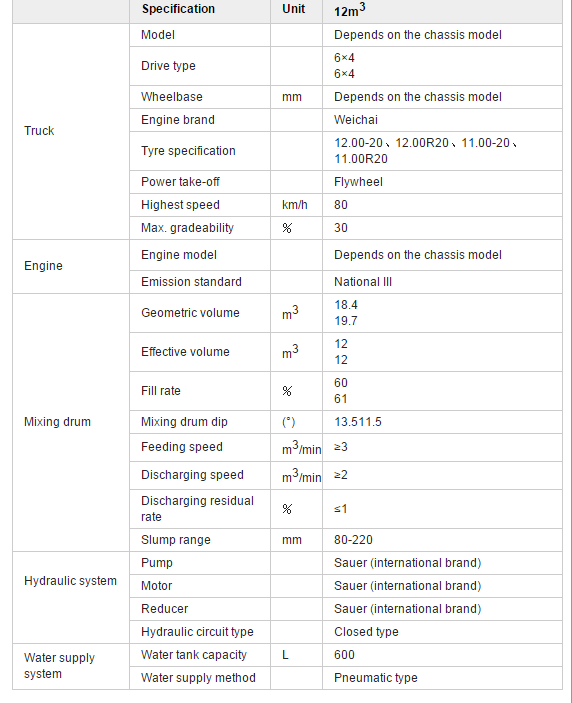

12m³ Concrete truck mixer / ISO & CE certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 8 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

12m³ Concrete truck mixer / ISO & CE certificate

Specification

Hydraulic system

•The split hydraulic system features low cost and easy maintenance;

•The best hydraulic system assembly in the world.

•The company has good relationship with leading hydraulic system manufacturers. The hydraulic system is the most reliable, featuring compact structure and easy maintenance.

•The hydraulic pump suspension frame adopts U type bolt fixing, featuring good interchangeability and easy maintenance; It adopts Sauer hydraulic oil pump, motor and reducer.

Water supply system

•Large water tank capacity; One-time water using cycle is long;

•Pneumatic type water supply; Washing system, high water supply pressure, clean the feeding hopper and, discharging slot, tank and other equipment;

•One switch on the bottom of the cleaning system, which can discharge the water completely in winter.

•The water pump and shower nozzle are arranged reasonably, which are easy to operate.

Operation system

•It adopts the control method of mechanical linkage, and optimize the traditional operation structure, which is easier and more reliable for the operator.

•The cab adds the internal operation handle, which is easy for operation without getting off.

•Control the mixing and discharging speed by the throttle, and load (acceleration) and unload (acceleration) the material.

•Optimize the operation reliability, and eliminate the safety loophole.

Feeding and discharging system

•Add the quick coupler for watering, and the optimized hopper is easy to feed and discharge the concrete;

•The feeding height of less than 3850mm is suitable for the mixer, and the upper of feeding hopper is less than 650mm;

•The discharging height of 1350mm-1550mm is suitable for the feeding inlet of the pump;

Upper electrical system

•The electrical system is in single line, with negative pole on iron. The line voltage is 24V.

•The electrical system consists of illuminator, hydraulic oil temperature control switch, relay, and fan motor. When the oil temperature is over 60°C, the temperature control switch will connect and the cooling fan will rotate; when the oil temperature is below 55°C, the temperature control switch will disconnect and the cooling fan will stop.

•The work lamp switch controls the work lamp.

- Q:What is the driving license for a concrete mixer truck?

- Fees vary from anywhere from 2,500 to 3,500 Some places can be around 4,000 to 4500 The other thing is to get a certification, but the car on the site is generally unexamined.

- Q:What is the meaning of the word "concrete" in the concrete mixer jar?

- The "concrete" means "concrete" means "concrete". This is not to say that the car must print these two words, depending on the company. But I know the name of the company and the company.

- Q:How many cubic meters of concrete mixer transport vehicle

- Between 4m and 12m cubed, it is generally chosen according to the scale of the project, the use of the road environment and a concrete casting.

- Q:The concrete mixer transporter is running continuously for no more than one hour

- The concrete mixer transporter is running for no more than 8 hours. Concrete mixing is divided into two kinds: artificial mixing and mechanical stirring Manual stirring search When stirring, try to be quick, stirring time from adding water, should meet the following rules in general: The volume of the mixture is 4 ~ 5min (minute) under 30L. The volume of the mixture is 30L - 50L at 5-9min The volume of the mixture is 51L - 75L at 9 ~ 12min After mixing, it is required to do the slump measurement or the specimen forming according to the test requirement. The total operation must be completed in 30min from the beginning of the addition of water.Mechanical agitation First, it is the first batch, which is to make the ripper first, so as not to affect the mixing ratio of the mix. Start the mixer, blender, in turn, to join the gravel, sand and cement, stir evenly, add the water slowly again, all charging time not more than 2 min, water after all to join, to continue mixing 2 min.

- Q:Why is the concrete mixer turning on the road?

- Prevent concrete from being isolated and make concrete more uniform. In addition, the concrete is in a state of stagnation for a long time, and the vehicle shakes and the concrete will soon be compacted, and the pot will not move.

- Q:s the collapse of four concrete mixer trucks

- The caving degree is 4 cannot be transported by concrete mixer, the slump is put into and out of the tank car. The average slump is 100 to 120mm, and it is better not to transport the concrete transporter, preferably with a construction dump truck.

- Q:What are the three main parts of the concrete mixer car

- The three main parts of a concrete mixer are oil pump, motor and speed reducer. The function of oil pump: provide constant power for hydraulic oil. The function of the motor: converts the power of the hydraulic oil into mechanical power and is transmitted to the decelerator. Decelerator: reduce the speed of the hydraulic motor

- Q:What is the difference between a concrete mixer and a tanker?

- Concrete mixers are also called concrete mixers, and they are called concrete transporters, which are actually a kind of thing.

- Q:How many cars do you have for a concrete tanker

- What kind of car is there, there are eight square, six square, and more

- Q:How does the concrete mixing truck work?

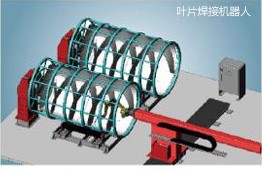

- Operating mechanism (1) control the rotating direction of the mixing cylinder so that it is rotating in the process of feeding and transportation. (2) control the speed of the mixer. The mixing device consists mainly of the mixer and its auxiliary supporting parts. Mixing drum of concrete loaded containers, rotates the concrete along the blade spiral direction, constantly in the process of ascension and turning by mixing and stirring. In the process of feeding and transportation, the mixing cylinder is turning, the concrete is moving in the blade, and the mixing cylinder is turned and the concrete is removed out of the blade. The blades are the main parts of the mixing plant, and the damage or severe wear and tear can cause the concrete to be mixed. In addition, if the design is unreasonable, the concrete will be isolated

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

12m³ Concrete truck mixer / ISO & CE certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 8 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords