1260C Low Thermal Conductivity Ceramic Fiber Blanket for High Temperature Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | HZ (High Zirconium) | Application: | Liners Of Industrial Furnace | Thickness: | 6-60mm |

| Width: | 610/1220mm | Length: | 3600/7200/14640mm | Chemical Composition: | Al2O3: 39-40% Zr02:15-17% |

| Ultimate Strength (≥ MPa): | 0.08-0.12 | Working Temperature: | 1050C | Fiber Diameter: | 3-5um |

| Shrinkage (1800 ℉, 3h): | -3% | Thermal Conductivity: | 0.09-0.16w/(m.k) | Density (kg/m³ ): | 96 |

| Model Number: | JK-ceramic fiber1260S-002 | Brand Name: | Place of Origin: | China (Mainland) | |

| color: | pure white | certificate: | CE ISO9001 | size: | customizable |

| sample: | available |

Packaging & Delivery

| Packaging Detail: | 1. Plastic bag inside and woven bag out side, 620rolls/1x40HQ 2. Plastic bag inside and carton out side, 525ctns/1x40HQ |

| Delivery Detail: | 3-15 days |

1260C Low Thermal Conductivity

Ceramic Fiber Blanket for High Temperature Kiln

Product Description

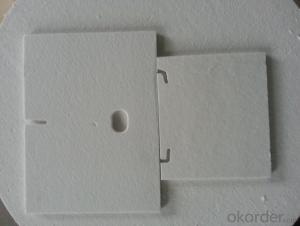

Ceramic Fiber Blanket

Ceramic Fiber Blanket is made of special ceramic longfiber that is produced by the melting of very pure raw materials in double surface meeding process without binders and with good stability in a large range of temperature.

The process of double surface needing increase interweaving and tensile strength. Ceramic fiber blanket is a needled blanket that has exceptional handling strength, while being flexible and lightweight. Ceramic Fiber Blanket is made of high purity Alumino-Silicate (and Zirconia) fibrous wool.

Product Information of Ceramic fiber blanket

Item |

Ceramic fiber blanket |

Classification Temperature

|

1100C 1260C 1420C 1600C |

Features of Ceramic fiber blanket |

v Needled blanket v Non-combustible v Low thermal conductivity v Shorter heat up and cool down time v Resilience and resistance to thermal shock v Flexible and easy to cut or install v Consist of acoustic properties v Contain no organic binder v Asbestos free v Resistance to burning v Low thermal capacity v Good insulation v Good obstructing voice and mechanism strength v Low shrinkage v Good springiness for fibers v Convenient producing and installing

|

Application of Ceramic fiber blanket |

v Refractory back-up installation v Direct exposure to heat as furnace hot face lining v Expansion joint seal v Fire protection v General high temperature insulation v Lining for furnaces, kiln and oven v Expansion joints and seals for furnace, kiln and oven v Back-up installation v Lagging of high temperature pipe work v High temperature filtration v Steam turbine and nuclear insulation v Fire protection |

-Professional high temperature furnaces Manufacture We have being specialized in producing high temperature furnaces for more than 10 years, and all our products are exported.

--Guaranteed Quality Our furnaces are warranted to be free from defects in materials or workmanship for 2 years from the date of purchase. Within this period, Across International will, at its sole options, replace any components that fail in normal use. Such replacement will be made at no charge to the customer for parts, provided that the customer shall be responsible for any transportation cost. This warranty does not cover consumables and failures due to abuse, misuse, accident or unauthorized alteration or repairs.

--Sound after Sales Service We provide sound after sales service. We provide 24 hours’ consultation service. We are ready to answer your consultations at any time.

Packaging & Shipping

Exported Package

1. Plastic bag inside and woven bag out side, 620rolls/1x40HQ

2. Plastic bag inside and carton out side, 525ctns/1x40HQ

- Q:Definition of ceramic fiber

- 1. Definition of ceramic fiber:Ceramic fiber is a fibrous lightweight refractory.2, ceramic fiber expansion:Ceramic fiber, also known as aluminum silicate fiber, is the main component of refractory fiber!HLGX ceramic fiber is the refractory material with the lowest thermal conductivity and the best heat insulation and energy saving effect except the nanometer insulation material. The utility model has the advantages of light weight, high temperature resistance, good heat insulation effect, convenient construction, etc., and is a lining material of high quality industrial furnaces. Ji'nan dragon hot Ceramic Co., Ltd. has HLGX ceramic fiber module, HLGX ceramic fiber blanket and other ceramic fiber products widely used in kiln insulation project, high temperature equipment, pipe insulation.3. The origin of ceramic fiber appellation:First of all we want to know the origin and development of ceramic fiber, ceramic fiber first appeared in 1941, the United States Babu Hancock. Cox Newell company with natural kaolin by the arc furnace melt blown fiber. In 1950s, the ceramic fiber was put into industrialized production. In 60s, a variety of products were developed and used as lining for industrial furnaces.Thus, we know that ceramic fiber originated in the United States, and its name "Ceramic Fiber", literally translated literally "Ceramic - ceramic, Fiber - fiber, combination is" ceramic fiber".

- Q:The characteristics of ceramic fiber paper

- 1, high strength tear resistant 2, high flexibility 3, low slag ball content 4, accurate thickness 5, thermal shock 6, very low thermal conductivity

- Q:The product characteristics of ceramic fiber cloth?

- Product characteristics:High temperature resistance, low thermal conductivity, thermal shock resistance and low heat capacity;

- Q:Which expert to help, urgent?! Thank you, 20Is the type of refractory material, shaped like cotton mattress like, but not really cotton, is some ore and some artificial material is made into the refractory with high temperature of one thousand degrees, will not change the kind of.

- Aluminium silicate refractory fiber cotton custom HS Code: 68061000.9068129900 refractory fiber cotton (containing asbestos)84748090 aluminium silicate refractory fiber cotton and its product line equipment

- Q:What is the difference between the national standards for ceramic fiber products and ordinary aluminium silicate?

- Generally high alumina content, iron oxide and other impurities of low fiber products are pure white, the introduction of chromium oxide fiber is sold with milk yellow tone color. The average diameter of ceramic fiber products (aluminium silicate fiber products) is 22 - 33 microns. High fiber, small density, low thermal conductivity, high temperature. If the fiber is coarse and dense, the use is not satisfactory. The thermal stability index of ceramic fiber products (aluminum silicate fiber products) is more important. The range of Al2O3SiO2 fiber contraction in various products of 1260 C line is 35 - 88%. The amount of shrinkage is also directly related to thermal stability. Ceramic fiber products (aluminum silicate fiber products) as ceramic fiber products (aluminum silicate fiber products) with low thermal conductivity, low density, light weight, light steel frame are used in the design and construction of kilns supporting structure, so that the development of ceramic kiln kiln into the "lightweight" era. The fiber has small heat storage and is suitable for quick heating and cooling firing.

- Q:What is the use of ceramic fiber paper?

- Specifications: 10mm-- diameter, infinite product features: 1) continuous use temperature of up to 1000 degrees, a short time using temperature of 1260 degrees. 2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.

- Q:How to choose the right ceramic fiber and aluminum silicate products?

- 3, according to the thickness of insulation to chooseThere are a lot of insulation thickness of furnace is fixed, the insulation thickness of conventional material is inappropriate, only according to the heat flow calculation formula to calculate the appropriate level of insulation material is the most scientific, the conventional case raised to two of the product can be registered.

- Q:What brand of ceramic fiber products is best?

- The quality of the above products can be highlighted from two aspects:1, large-scale production2, the application of advanced technology3, brand awareness of the high and low

- Q:What is the customs code for ceramic fiber products?

- The customs code should be 6914.9000Specific can be seen by the Chinese customs published in 2005 edition of import and export commodity names and codes, thirteenth and sixty-ninth chapters, ceramic products, P166-168 pages.

- Q:Slag ball content of ceramic fiber material?

- 2800 ~ 3200kg/m the data of fand, right?Chasing the answerThis value is 2800 ~ 3200kg/m fand slag ball density, not ceramic fiber density

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1260C Low Thermal Conductivity Ceramic Fiber Blanket for High Temperature Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords