1260c Ceramic Fiber Blanket with Alumina Silicate

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Ceramic Fiber Blanket is made by continuous processing method. The fiber interweave shapely after being needled. It has excellent tensile strength. The blanket do not contains any bonding agent.

Ceramic Fiber Blanket not only can resist the chemical species, but also the hydrofluoric acid, phosphoric acid and strong base. The Fiber Blanket has excellent capability of resisting the oil. After being dried, it will repossess the thermal characteristic and the physical feature.

Ceramic Fiber Blanket Applications:

-Industrial kiln, heating device, high-temperature pipeline wall lining.

-Heat insulation of electric boiler, steam turbine and nuclear electricity.

-Wall lining of chemical high-temperature conversion unit and heating equipment.

-Fireproof and heat insulation of tall buildings.

-Materials of high-temperature filtration.

Ceramic Fiber Blanket Advantages:

-Low heat conductivity and thermal capacity

-Excellent thermal stability and shock resistance

-Excellent heat insulation, fireproof and sound insulation

Main Product Features:

1. High quality

2. High working temperature.

3. Fast delivery and very competitive prices.

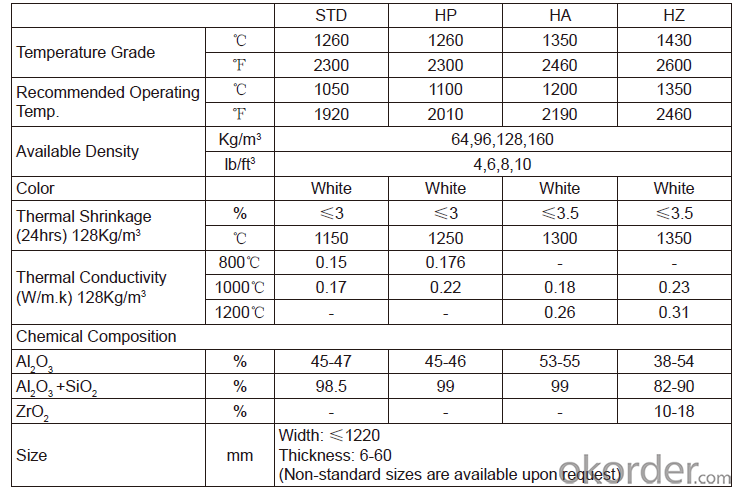

Product Specifications:

FAQ:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:Is fanfold insulation or foam (rigid) insulation better to put under the vinyl siding?

- You probably missed a good 15 mins of the movie.

- Q:Okay, my hair is really fizzy and really poofy!! i am ashamed to go out in public at times!! i need advice on how to make it straight and losse it's poofyness!! i don't want to use product bcasue i have had enough of them!! and i don't want to damage it with flat irons and all that crap!! plz HELP!! i had also bought a round brush and i can't work it.so could you also tell me how to use it?? PLEASE?? i know i sound helpless.i am!!

- replace your scale with a tape measure aim for 32 1 2 inches or less for women and 35 inches or less for men

- Q:A tailor messed up the ribbed detailing on the sleeves of a merino wool sweater of mineI want to attempt to recreate and fix it myself but I need help finding a yarn that is going to matchHow do I count stitches, and how do I determine from stitch count, what yarn weight and needle size to use?

- I haven't had any personal experiences which would make me distrust someone just because he or she was blackI have been suckered into giving money to someone for a serpentine belt and the next day when I was telling other attorneys about the guy they all laughed at meHe's a regular in that localeBut I've got similar stories about white panhandlers I've gotten death threats due to my career, but they've come from white criminals(It's basically stupid to send your own attorney a death threat, btw lol)

- Q:List 5 different uses for cotton, outside the home.

- is it cotton wool or cotton fabric ? cotton-wool is used in hospitals medical centres, to spin yarn, to make fabric, for stuffing in mattresses, cushions/pillows to stuff in furniture - sofas, et al to make soft toys other crafts to make cotton-balls, etcin cosmetics fashion industry cotton fabric can be used for various purposes in the garment industry, to make linen for hospitality industry again, in hospitals, for beds, swabs, uniforms, for uniforms in various factories/industries to make accessories, crafts, etchope these get you started

- Q:are cheerios cerials high in fiber?

- Id say frosted mini wheats and yogurt would do the trick!

- Q:Do you think I could do it myself? I am 32 and in pretty good shapeshould I just go to Lowe's and buy some and roll it up there?

- blowing is generally the best if you use fiberglass rolls run them in opposite direction of insulation below your attic in cold climates should be at least R-40 but if you exceed R-50 it doesn't help muchyou need to make sure you do not block your roofs venting if your eaves are vented they sell Styrofoam units (proper vents) to maintain this, very important or you could end up with condensation problems! if yo do blow it a trick to help keep even depth is every 10' or so put a stick set to the height you want it keeps the insulation at proper height without wasting it to heavy, or to thin inadequate

- Q:I have 2 two-year old pit bulls, a one-year old chihuahua and a 5 month old chihuahuaI noticed a hole in my wall where one of my dogs ate through itThere is pink insulation all tore up- about 1 foot by 1 foot square or so (not completely eaten, but possibly nibbled on)Now one of my pit bulls and my 5 month old chihuahua appear to be losing their hair around their body (not complete bald spots, but balding)They haven't lost their appetite or energy and I don't see blood in their poopie, but am curious if they can die or can they get betterPlease don't be cruel about me having pit bullsThey are very sweet and as you can see, they get along great with my chihuahuasI am just a concerned pet owner who is having a little bit of a financial situation which is the reason I can't go to the vet at this momentThank you in advance for those who help.

- Insulation ( pink ) between the walls is FIBERGLASS insulation, and is very hard on the tummyIt'll tear it up insideMy advice.take all of your dogs to the vet and have xrays made of their stomach / intestinesIt's entirely possible that they may have to have surgery to get it out.and the longer you wait, the worse it COULD beOther than making sure you close up the hole, and they don't eat any more of the insulation.there's nothing you can do for them at homeHope you get the xrays, and they turn out to NOT have any insulation inside them.GOOD LUCK.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1260c Ceramic Fiber Blanket with Alumina Silicate

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords