1260 Ceramic Fiber Blanket in 7200*610*25mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Blanket

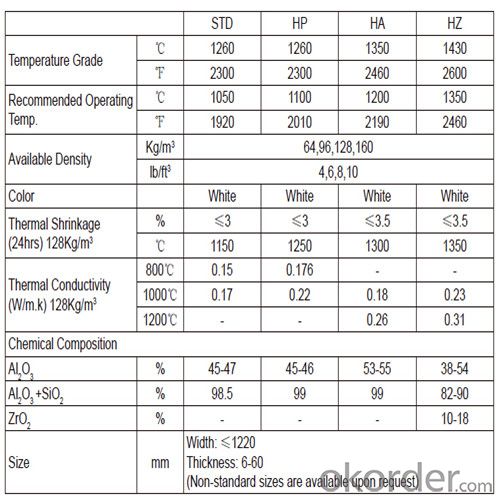

CMAX ceramic fiber blanket is made from high quality Gao-Ling clay, high purity alumina and silica oxides by spun or blown process. Ceramic fiber blanket is asbestos free. Double-side needling provides blanket with great tensile or handing strength for easy installation.

Ceramic fiber blanket are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000℃,1100℃,1200℃ and 1350℃

Feature of Ceramic Fiber Blanket

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Resilient to thermal shock

High tensile strength

Application of Ceramic Fiber Blanket

Petrochemical process heater refractory fiber lining

Heat treating furnace or Intermittent(shuttle) kiln hot face lining

General furnace backup insulation

Heat seals for kiln car or furnace door

Electrical insulator

Images of Ceramic Fiber Blanket

Technical Data of of Ceramic Fiber Blanket

Who We Are

OKorder is offering high quality Ceramic Fiber Blanket at great prices with worldwide shipping. Our supplier is a world-class manufacturer of ceramic fiber products, with our products utilized the world over. OKorder annually supplies a full range of products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Why Choose Us

We are a government owned company with ISO certificate.

We are listed in Global Fortune 500 with D & B report.

We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, monolithic material, ceramic fiber products, and more.

Q4: If I need your offer, what information do you need?

A4: In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q:woven fabric ,adft

- What you are actually losing is either fat or muscle, both of which are full of calories and that's what you burn when you work out.

- Q:what is the difference between high fibre flour and whole wheat flour?

- Was searching for an answer on this too

- Q:how does it work for your diet? does it have calories? if yes how many calories for 1 grame of fiber? should i eat high calories food with high fiber or low calories food with low fiber?please help me i am really confused what would be more helpful for diet, calories or fiber.?

- You want high fiber in low calorie foodsI had a hard time incorporating fiber into my diet so I take a teaspoon of Metamucil in cold water 15 minutes before every mealIt helps to fill you up so you don't eat as much and the fiber helps to digest your food so that its not just sitting around in your gutThey also make fiber products that you can sprinkle on any of your food or add into your drinks.

- Q:I need help on how the juice fast actually works.-Can i by juice at a store or do i have to buy a juicer and fruits?-How many glasses of juice do i have to drink a day?-Can i take any medicine for headaches?please help! I really need to lose weight for my health.170 lbsfor a 17 yrold and being 5'3 isnt good.

- I have had two types of insulation in different homes, and both did good jobs at reducing the heat bills, and keeping the upper rooms cool in the summerYou only insulate the horizontal area of the floor of the atticEnsure that the venting is clear of insulation for good ventilation on completion1) Pink Fibreglass - installed in battings 2) Celulose - sprayed in place.

- Q:Well, recently, I've decided to go vegetarian, mainly because of health ecological reasonsThen I saw that quot;Meet your Meatquot; video, and it became a combination of Health, Ecological, and Saving the Animals.Anyways, after today had ended, I recorded what I ate, and how much I got of each 'nutritional factquot;I hadn't noticed how much of a healthy eater I normally am ( as today, I basically ate what I'd eat on a normal day.and it turned out to be lacto-vegetarian )One thing that I noticed, that I thought was strange, was that I had consumed 35g of fiberThe normal is 25gI didn't eat many fruits, besides 4 clementine orangesThe bread I ate says that it gives 6g a slice, and I had 4.So how do vegetarians do it? With such a high intake of fiber from fruits, vegetables and grains.is it normal to eventually develop a higher intake of fiber?Also, the fiber listed on the nutritional facts, are there things that quot;cancelquot; out the fiber grams?

- Take a glass of water with flaxseed (alsi) in an empty stomachThis will provide you with the omega 3 acid that you need for hair growthBegin every day with one amlaSoak 5 almonds every night in water and eat them with their skin onYour scalp needs nutritionSo get plenty of fluids like buttermilk, lime juice and coconut waterDrink at least 8-10 glasses of water every day One bowl of sprouted pulses for would be great.

- Q:I want to keep frozen meat cold without a coolerBubble wrap has been suggested to me, but I don't have anyWhat else could I use that would provide the best insulation?I have tin foil, freezer bags, wax paper, plastic wrap, newspaper, and various other common items.Thanks!

- A project? Bet it is, but I get the feeling it's not for a SCHOOL project.

- Q:I know losing weight will not happen overnight.I have been exercising every other day for 2 weeks.I've heard the saying quot;80% diet,20% exercisequot; I think that's what it is.But I was wondering what other things can help me maintain my progress?Are there any vitamins/pills I can take?Full-filling food I can eat/drink?I drink tea a lot.I start to get hungry right after I eat.I've done research but what have you done that successfully made you lose weight?

- I lost the most weight, 10 pounds, in a monthI did not count caloriesI did not exerciseI cut out fast food, ate more fruits and veggies My daily diet consisted of: Breakfast: Some sugar filled cereal with low fat milk (I do not do this anymoreAfter months of working out and eating clean, I suggest oatmeal or eggs for breakfast.) Lunch: Chicken/Beef with salad Dinner: Bread with eggs and various cheeses and veggiesI do not suggest this diet to anyoneI lived a month in the middle east and although that is not what my diet consisted of daily, that is what I ate when I was at homeWhen I went out I enjoyed many Mediterranean foodsI still lost ten poundsI lost five pounds before my trip by eating healthyThat meant eggs/bacon (yes, I eat baconI enjoy it about once a week) or fruits for breakfastLunch was whole grain bread with turkey and spinach sandwichesDinner was full of grilled chicken and salad I had lost a total of 15 pounds before I started weight liftingThe first couple weeks that I started weight lifting (I also did cardio in the morning, powerwalks), I lost 3-4 more poundsThen I started gaining weight and now I don't really check my weight because even though I have lost inches, my weight has still stayed the same No pills, no special dietJust work hard and stay consistent.

- Q:I have curly hair but I think I look better with straight hair it would be a lot easier to manage if it were straightI have thought about getting it professionally straightened but am pretty ignorant about how it worksCould someone explain how they do this and if there is more than one method that hairdressers use? The reason I am worried about doing it is because I don't hate my curly hair and I would like to be able to return to my natural texture and don't want crazy half-curly half-straight hairCould straightening it alter the texture of my hair permanently? How long would a treatment last and how would I go about getting it back to normal?

- significant rooms that are used maximum, furnish vents would desire to be one hundred%different room set vents at 40 5 degree or approximately 0.5the different element, you may desire to do is administered the blower for all time, yet you will prefer and could exchange your furnace filter out each 30 days with a elementary pleated filter outIF you had zone sensors they may be fastened on the wall approximately 2x 2 which isn't very elementary in properties, a riskthe priority with those say in case you have them is they take an time-honored temp analyzing so on an identical time as some rooms would desire to sense ok, different do no longerthe different element is the place is the return or returns? in case you only have a million needed return downstairs and if it a risk to function one up stairs then working the blower will help stability out the burdenthe different concern is you have gotten a loss of furnish vents for the down stairs and or loss of returnhard to declare without observing it.

- Q:What are some mushrooms that are high in fiber but low in digestive carbohydrates?

- the aluminum tubes that are made to have Uranium in - are not made for anything else and are truely unique to just that sort of containment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1260 Ceramic Fiber Blanket in 7200*610*25mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products