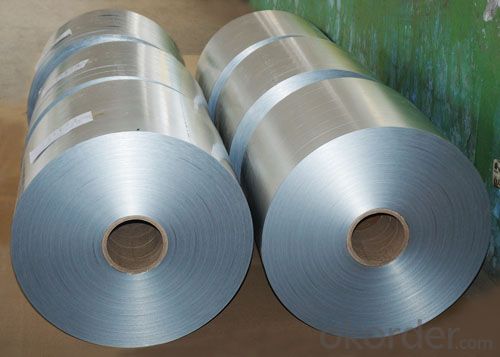

1235 Aluminum Alloy Coil H24 Temper Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1235 Aluminum Alloy Coil H24 Temper Aluminum Coil

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q:Can aluminum coils be welded or soldered?

- Aluminum coils possess the capability of being both welded and soldered. The fusion of aluminum coils can be achieved through welding or soldering, which are two widely employed techniques in this regard. Welding entails the melting of the aluminum material within the coils, followed by the application of heat and pressure to bind them together. This particular procedure necessitates the utilization of specialized equipment and skilled operators. Conversely, soldering is a process that utilizes solder, a filler material with a lower melting point, to connect the aluminum coils. Soldering is commonly employed in lighter applications and necessitates less heat compared to welding. Both welding and soldering are effective methods for joining aluminum coils. However, the selection between these two techniques depends on the project's specific requirements, the availability of equipment, and the proficiency of the operator.

- Q:How are aluminum coils cleaned and maintained?

- Aluminum coils are typically cleaned and maintained by following a few key steps. Firstly, any loose debris or dirt should be removed using a soft brush or vacuum cleaner. Then, a mild detergent solution or a specialized coil cleaner can be applied to the coils, followed by gentle scrubbing with a soft brush to remove any stubborn dirt or grime. It is important to rinse off the cleaning solution thoroughly using a hose or pressure washer, ensuring no residue is left behind. Regular maintenance includes checking for any signs of damage or corrosion, and if required, applying a protective coating or lubricant to prevent future issues.

- Q:Can aluminum coils be used in the production of aluminum windows?

- Yes, aluminum coils can be used in the production of aluminum windows. Coils are often used to create the frames and profiles of aluminum windows, as they can be easily shaped and formed into the desired configurations. This makes aluminum a popular material choice for window manufacturers due to its lightweight, durability, and corrosion-resistant properties.

- Q:Can aluminum coils be used for electrical connectors?

- Certainly! Electrical connectors can indeed utilize aluminum coils. This metal, widely employed for electrical connectors, boasts exceptional electrical conductivity, a relatively affordable price, and lightweight characteristics. It finds extensive application in diverse electrical domains such as power transmission, distribution systems, electrical motors, and transformers. Nonetheless, it is crucial to prioritize adequate insulation and protection for the aluminum coils to avert corrosion and guarantee enduring dependability for the electrical connections.

- Q:I am looking for a deoderant that doesn't contain aluminum that actually works. I have tried Tom's natural deoderant and didn't get to use it long enough to see if it worked because it really irritated my skin and caused it to burn and peel. I have also tried the one made by Adidas and it seemed to work pretty well through the winter months, but now that it is getting warm again I'm noticing that it isn't quite doing the job anymore.

- aluminum zirconium is the chemical that makes you stop sweating, not that it works on most people. they can only put a certain percentage of it in deodorants, try the degree clinical, i just started using it and it seems to be doing okay, good luck i know what you are going through.

- Q:Can aluminum coils be used in extreme temperature conditions?

- Yes, aluminum coils can be used in extreme temperature conditions. Aluminum has a high thermal conductivity and is resistant to corrosion, making it suitable for various temperature extremes. Additionally, aluminum's low melting point allows it to withstand high temperatures without deforming or losing its structural integrity.

- Q:Are aluminum coils suitable for insulation purposes?

- No, aluminum coils are not suitable for insulation purposes.

- Q:I am a college student living in a private apartment and I use up lots of aluminium foils to cook and eat. I use aluminium foils as plates because I am too lazy to clean plates. I want to know how environment-unfriendly i am for doing so. How bad am I compared to the guy who keeps on drinking from cans without recycling them?

- Are you recycling them? If so it could be quite interseting as you are not using detergent and water to wash up? Who knows? How bad do you feel? I imagine that it's not great in the big scheme of things as re-using is the best option before re-cycling.

- Q:I have a diamond back bike with an aluminum frame. will it rust if i ride or put it in the frame? is it bad for the bike?

- Aluminum frames do NOT rust the corrode and unless you live close to the ocean you have little to worry about with the frame. it will be the other components on the bike like the wheels and spokes that may rust if the bike is left outside. If you didnt pay much for the bike then plan on some rust if you leave it out!

- Q:What is an aluminum coil and what is it used for?

- An aluminum coil, shaped like a rolled-up sheet of aluminum, is made from high-quality aluminum alloys known for their durability, lightweight nature, and resistance to corrosion. Aluminum coils are widely used in various industries, particularly in the manufacturing sector where they are utilized to create aluminum products like cans, containers, and packaging materials. The flexibility and malleability of aluminum coils allow them to be easily shaped into different sizes and forms. Moreover, the construction industry extensively relies on aluminum coils for multiple purposes. These coils are commonly employed in roofing, siding, gutters, and other exterior applications due to their ability to withstand harsh weather conditions and resist corrosion. Their lightweight nature also simplifies handling and installation, reducing labor and transportation expenses. Furthermore, aluminum coils play a crucial role in heating, ventilation, and air conditioning (HVAC) systems. They are integral components in the production of condenser and evaporator coils, which are essential for regulating temperature and humidity in residential, commercial, and industrial buildings. To summarize, aluminum coils are highly versatile and valuable materials that have widespread applications in numerous industries. Their lightweight nature, resistance to corrosion, and malleability make them an excellent choice for manufacturing aluminum products, as well as for construction and HVAC applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1235 Aluminum Alloy Coil H24 Temper Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords