11mm*0.95kg/m square bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications

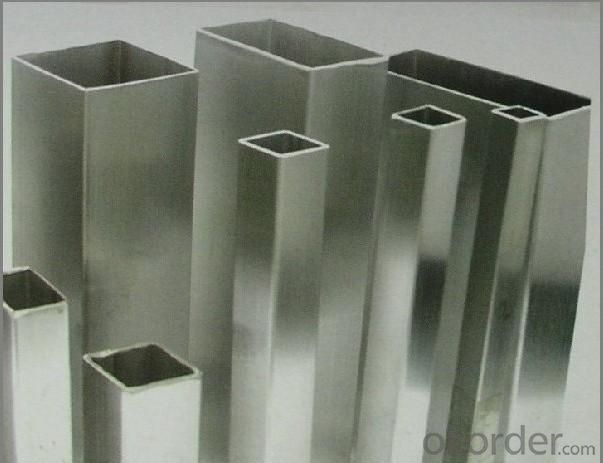

stainless steel square bar flat steel bar

Diameter:2-500mm

Length:Customized

Quality: High quality stainless steel bar

stainless steel square bar flat steel bar

Stainless Steel bar

Diameter:2-160mm

Length: Customized

Surface | bright,black |

Technique | Hot Rolled/Cold Drawn/Peeled |

1.Round bar 1Hot rolled black bar: (5~400x6000mm or according to your requirement. 2Acid round bar: (5~400)x6000mm or according to your requirement. 3Cold drawn bright bar: (1~20x6000mm or according to your requirement. 4)Polishing round bar: (5-400)x6000mm or according to your requests. | |

2. Square bar 1)Hot rolled black bar: (5*5-400*400)x6000mm or according to your requests. 2)Acid square bar: (5*5-400*400)x6000mm or according to your requests. 3)Cold drawn square bar: (1*1-20*20)x6000mm or according to your requests 4)Polishing square bar: (5*5-400*400)x6000mm or according to your requests | |

Diameter± | H9 tolerance can reach the industry standard |

Quality | Our production equipment 24 hours of continuous temperature work, to ensure the unity of the product roundness, elongation, tensile strength and yield strength. Welcome customers to our company to detect the products before shipment. For the customers who are not inconvenient, quality assurance can be laid down in the contract, we will take charge of the returning and shipping fee if there is any problems of the product quality, so it will dismiss any of your worry about our products. |

Package | Standard seaworthy packing(plastic&wooden) or according to the customer's requests |

Delivery time | 7-20days, according to the quantity |

Productivity | 10000 tons/month |

Stainless steel round bars:

Grade :200 series 300series 400series. (Standard: ASTM JIS DIN & BS)

Diameters: 4mm-300mm

Surface : white acid , annealed, black(hot rolled) , bright and following customers request.

Length: 6M(standard) or random

Packing: standard export packing or following customer’s demand.

- Q:How do you use a steel square to create parallel lines?

- In order to generate parallel lines, one must adhere to a few straightforward measures when utilizing a steel square. Firstly, position the steel square on the designated surface or material where the parallel lines are desired. It is essential to ensure that the longer side of the square aligns parallel to the material's edge. Subsequently, employ a pencil or scribe to mark a straight line along the steel square's edge. It is crucial that the line is of sufficient length for the intended parallel lines. Once the initial line has been created, proceed to slide the steel square along the edge, guaranteeing alignment with the previously marked line. Continuously verify that the longer side of the square remains parallel to the material's edge. Using the same pencil or scribe, proceed to mark another line along the steel square's edge. This line should run parallel to the first one that was made. Repeat this procedure as many times as necessary to achieve the desired quantity of parallel lines. On each occasion, shift the steel square along the edge and delineate a fresh line that is parallel to the preceding one. By employing a steel square in this fashion, one can effortlessly produce precise and parallel lines on a diverse range of materials, such as wood, metal, or paper. The steel square acts as a guide, ensuring the maintenance of parallel alignment and accuracy in measurements.

- Q:Can a steel square be used for measuring the depth of holes?

- Indeed, the depth of holes can be measured with a steel square. By positioning the elongated, straight side of the steel square parallel to the hole's opening, and aligning the perpendicular side with the hole's vertical surface, one can accurately assess the hole's depth. Simply by attentively noting the intersection point between the perpendicular side and the hole's top, the depth can be deduced by examining the markings etched on the steel square.

- Q:Can a steel square be used for marking circles?

- No, a steel square typically does not have the necessary features or flexibility to accurately mark circles.

- Q:Can a steel square be used for framing?

- Yes, a steel square can be used for framing. A steel square, also known as a framing square or carpenter's square, is a versatile tool commonly used in construction and woodworking. While traditional framing squares are typically made of wood or aluminum, steel squares offer additional durability and sturdiness. They consist of a long arm (body) and a shorter arm (tongue) that meet at a 90-degree angle, forming an L-shape. The body of the square is usually 24 inches long, and the tongue is usually 16 inches long. Steel squares have various markings and measurements along their edges, which make them useful for framing tasks. They can be used to lay out and mark straight lines, accurately measure angles, determine levelness and squareness, and check the alignment of walls, doors, windows, and other components during the framing process. Steel squares are especially beneficial when working with metal framing or when extra strength and durability are required. They are also resistant to warping and bending, ensuring precise measurements and reliable results. In summary, a steel square is a suitable tool for framing purposes due to its strength, durability, and versatility. It is commonly used by carpenters, construction workers, and woodworkers to ensure precise and accurate framing measurements and alignments.

- Q:Can a steel square be used for checking the alignment of a planer table?

- Yes, a steel square can be used for checking the alignment of a planer table. A steel square is a versatile tool that is commonly used in woodworking and construction for measuring and checking angles, as well as testing for squareness and alignment. To check the alignment of a planer table, you can place the steel square against the edge of the table and make sure it is flush with the surface. By visually inspecting the square against the table, you can determine if the table is aligned properly or if it needs adjustment. Additionally, you can use the steel square to check the alignment of the fence or other components of the planer to ensure accuracy and precision in your woodworking projects.

- Q:Can a steel square be used for deck stair layout and construction?

- Deck stair layout and construction can benefit greatly from the use of a steel square. Also known as a framing square or carpenter's square, this versatile tool is widely used in woodworking and construction. With its long and short arms forming a right angle, the steel square serves various purposes. Specifically for deck stair layout and construction, the steel square proves to be highly advantageous. It aids in determining the precise angles required for cutting the stringers, which provide support for the stairs' treads and risers. By employing the steel square, one can accurately mark and measure the angles necessary for creating each step. Moreover, the steel square assists in verifying the levelness and alignment of the stringers throughout the construction process. It ensures the even spacing of the steps and the uniform height of the risers, both crucial for the stairs' safety and functionality. All in all, the steel square is an invaluable tool for deck stair layout and construction. It facilitates precise angle measurement and marking, as well as guarantees proper alignment and levelness of the stairs. However, it is imperative to possess a solid understanding of correct steel square usage to achieve the desired outcomes.

- Q:Can a steel square be used for checking the squareness of a cabinet frame?

- The squareness of a cabinet frame can be checked using a steel square. This versatile tool, also known as a framing square or a carpenter's square, is commonly used in carpentry and construction work. With a 90-degree angle at one end and a 45-degree angle at the other, it is perfect for examining the squareness of objects. To determine if a cabinet frame is square, position the steel square against the frame's edges. The corners of the frame should align perfectly with the 90-degree angle. Any discrepancy or space between the square and the frame signifies that the cabinet frame is not completely square. By utilizing a steel square, the cabinet frame's corners can be guaranteed to be at right angles, ensuring proper assembly and installation. This tool is highly valuable for maintaining accuracy and precision in woodworking projects.

- Q:Can a steel square be used for checking the plumbness of a wall?

- No, a steel square cannot be used for checking the plumbness of a wall. A steel square, also known as a carpenter's square or a framing square, is primarily used for measuring angles and ensuring straight lines in carpentry and woodworking projects. It is not specifically designed for measuring plumbness or vertical alignment. To check the plumbness of a wall, a level or a plumb bob is typically used. A level is a tool consisting of a straight edge with a bubble vial filled with liquid that helps determine if a surface is perfectly vertical or plumb. On the other hand, a plumb bob is a weight attached to a string, which is suspended from a fixed point. The plumb bob aligns vertically due to gravity, allowing for the measurement of the wall's plumbness. Therefore, while a steel square is a useful tool for various carpentry tasks, it is not suitable for checking the plumbness of a wall.

- Q:How do you use a steel square to lay out a circle?

- To use a steel square to lay out a circle, you will need to follow a few steps. First, determine the diameter or radius of the circle you want to lay out. The diameter is the distance across the circle, while the radius is the distance from the center to any point on the circle. Next, position the steel square with one edge aligned along the diameter or radius line. Ensure that the square is securely held in place so that it does not move during the process. Then, locate the 90-degree angle of the steel square, which is the corner where the two arms of the square meet. This angle will serve as the starting point for laying out the circle. Using the 90-degree angle as a pivot point, rotate the steel square smoothly along the diameter or radius line. While rotating, mark several points along the circumference of the circle with a pencil or a marker. The number of points you mark will depend on the accuracy and smoothness of the rotation. Once you have marked enough points along the circumference, connect these points with a curved line to form the outline of the circle. You can use a compass or a flexible curve ruler to ensure a smooth and accurate curve. Lastly, double-check the measurements and make any necessary adjustments to ensure the circle is properly laid out. This includes verifying the accuracy of the diameter or radius and checking the smoothness of the curve. By following these steps, you can effectively use a steel square to lay out a circle with precision and accuracy.

- Q:Can a steel square be used for siding installation?

- Siding installation can benefit from the use of a steel square. This tool, also known as a framing square or rafter square, is commonly employed in carpentry and construction due to its versatility. While its main function is to measure and mark right angles, it can also serve as a guide for cutting and installing siding. When it comes to siding installation, a steel square proves useful in guaranteeing precise and accurate measurements for both horizontal and vertical cuts. It aids in marking the angle and length of cuts on the siding material, leading to a seamless fit and professional finish. Moreover, a steel square can be utilized to verify the alignment and squareness of the siding during installation. This step is crucial to ensure the siding is level and straight, preventing potential issues or gaps in the final outcome. In summary, a steel square is an invaluable tool for the siding installation process. Its measuring, marking, and guiding capabilities assure correct installation, resulting in an aesthetically pleasing and long-lasting exterior for any structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

11mm*0.95kg/m square bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords