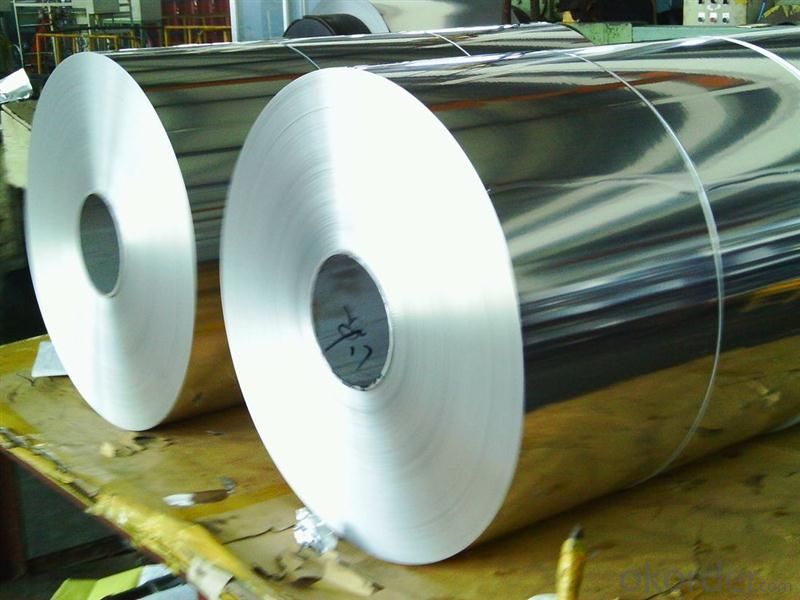

1100 Temper H18 0.5mm 0.8m 1mm Thickness Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1100 Temper H18 0.5mm 0.8m 1mm Thickness Aluminum Roll

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q:Can aluminum coils be used in electrical or electronic applications?

- Yes, aluminum coils can be used in electrical or electronic applications. Aluminum is a highly conductive material and has several advantages over other materials, such as copper, when it comes to coil applications. Aluminum coils are lightweight, which makes them suitable for applications where weight is a concern. They also have good thermal conductivity, allowing for efficient heat dissipation. Additionally, aluminum coils are corrosion-resistant, making them durable and suitable for outdoor or high-humidity environments. However, it is important to note that aluminum has a lower electrical conductivity compared to copper, so the design and dimensions of the coil need to be carefully considered to ensure optimal performance.

- Q:What is the typical thickness of an aluminum coil?

- The thickness of an aluminum coil can differ depending on its intended purpose and use. Generally, aluminum coils can have a thickness ranging from 0.006 inches (0.15 mm) to 0.25 inches (6.35 mm). Thinner coils are frequently utilized for lightweight applications like packaging materials, whereas thicker coils are commonly found in industries such as construction, automotive, and aerospace, where strength and durability are crucial. It is worth mentioning that the precise thickness requirements may vary depending on the unique needs and specifications of the project or product being manufactured.

- Q:How are aluminum coils cleaned and maintained?

- Regular cleaning is essential for maintaining the optimal performance and efficiency of aluminum coils, which are commonly used in HVAC systems and refrigeration units. Here's a step-by-step guide on how to clean and maintain them: 1. Prioritize safety: Before starting the cleaning process, ensure that the power to the HVAC system or refrigeration unit is switched off to prevent accidents. 2. Remove debris: Begin by getting rid of any visible debris like leaves, dirt, or dust from the aluminum coils. Use a soft brush or a vacuum cleaner with a brush attachment to gently eliminate the debris. 3. Apply a cleaning solution: Create a cleaning solution by mixing water with a mild detergent or coil cleaner. Follow the instructions on the product label to achieve the proper dilution ratio. Transfer the solution to a spray bottle. 4. Use the cleaning solution: Spray the cleaning solution onto the aluminum coils, ensuring that all areas are covered. Allow the solution to sit for a few minutes to loosen any dirt or grime. 5. Gently scrub the coils: Use a soft brush or a coil cleaning brush to gently scrub the aluminum coils. Take care not to apply excessive pressure, as it may damage the delicate fins on the coils. Concentrate on areas with stubborn dirt or buildup. 6. Rinse with water: After scrubbing, thoroughly rinse the aluminum coils with clean water. You can use a hose or a pressure washer on a low setting to ensure that all the cleaning solution and dirt are removed. Make sure that the water flows in the opposite direction of the airflow to prevent pushing debris further into the coils. 7. Inspect for damage: While cleaning, inspect the aluminum coils for any signs of damage, such as bent fins or leaks. If you notice any issues, it is advisable to contact a professional technician for repairs. 8. Allow for complete drying: Once rinsed, allow the aluminum coils to air dry completely before turning the power back on. This will prevent any moisture-related problems and ensure that the coils are ready for use. 9. Maintain a regular cleaning schedule: To keep the aluminum coils in excellent condition, it is crucial to establish a regular cleaning schedule. Generally, cleaning every three to six months is recommended, depending on usage and environmental factors. However, if the coils are located in a highly polluted or dusty area, more frequent cleaning may be necessary. By following these steps and adhering to a regular cleaning schedule, you can ensure that your aluminum coils remain clean, efficient, and in optimal working condition.

- Q:What is the typical density of aluminum coils?

- The density of aluminum coils can differ depending on the particular alloy and manufacturing method employed. Generally, aluminum coils have a density of approximately 2.7 g/cm³. This value is slightly lower than pure aluminum, which has a density of 2.7-2.8 g/cm³. It should be noted that the density of aluminum coils can also be affected by factors such as coil thickness and any surface coatings or treatments applied.

- Q:What are the different coil uncoiling options for aluminum coils?

- There are several coil uncoiling options for aluminum coils, including manual uncoiling, mechanical uncoiling, and motorized uncoiling. Manual uncoiling involves manually unwinding the coil by hand, while mechanical uncoiling utilizes a mechanical device such as a uncoiler or decoiler to unwind the coil. Motorized uncoiling, on the other hand, involves using a motorized system to unwind and feed the coil. Each option has its own benefits and is chosen based on the specific requirements and volume of the aluminum coil being processed.

- Q:Are there any limitations on the surface treatment of aluminum coils?

- The surface treatment of aluminum coils has certain limitations. One limitation pertains to the type of surface treatment suitable for aluminum coils. Anodizing, painting, and powder coating are some options for surface finishes. However, not all treatments are suitable for every application. For instance, anodizing is a durable and corrosion-resistant finish but may not meet the requirements of applications that demand specific colors or designs. Similarly, painting and powder coating offer a wide range of colors and aesthetics but may not match the durability of anodizing. Another limitation concerns the size and shape of the aluminum coils. Surface treatment processes have size and shape restrictions for aluminum coils. For example, anodizing is typically performed in tanks or racks, which may have size limitations. Similarly, painting and powder coating processes may require specific equipment or facilities that cannot accommodate large or irregularly shaped coils. Furthermore, the condition of the aluminum surface affects the effectiveness of the surface treatment. Imperfections or surface defects on aluminum coils can impact the adhesion and durability of the treatment. Proper cleaning and preparation of the aluminum surface are crucial to ensure the effectiveness of the surface treatment. In conclusion, while there are various surface treatments available for aluminum coils, limitations exist regarding the type of treatment, the size and shape of the coils, and the condition of the aluminum surface. It is important to consider these limitations and select the most suitable surface treatment based on the specific requirements and constraints of the application.

- Q:I would like to know why the ionic substance aluminium oxide doesn't dissolve in water.

- It does dissolve, but only slightly. It has a solubility of about 0.0001 under atmospheric pressure, it doesn't dissolve because the aluminium is extremely strongly bonded to oxygen, so it can't dissociate very much at all. If you want to dissolve aluminium oxide, you should use an alkaline solution.

- Q:How do aluminum coils compare to other non-ferrous metals like titanium?

- Aluminum coils and other non-ferrous metals like titanium have distinct characteristics that differentiate them in terms of their properties and applications. While both metals are non-ferrous and share similarities such as excellent corrosion resistance and lightweight properties, they have several differences that set them apart. Firstly, aluminum is more commonly used and readily available compared to titanium. It is also more affordable, making it a cost-effective choice for many industries. Titanium, on the other hand, is relatively rare and expensive due to its complex extraction process, limiting its widespread use. In terms of strength, titanium is significantly stronger than aluminum. Titanium alloys possess exceptional strength-to-weight ratios, making them suitable for applications where high strength is a requirement, such as aerospace and military industries. Aluminum, although not as strong as titanium, is still widely used in various industries due to its good strength-to-weight ratio. Another key difference lies in their melting points. Titanium has a significantly higher melting point compared to aluminum, making it more resistant to high temperatures. This characteristic makes titanium ideal for applications involving extreme heat, such as aircraft engines and components for the chemical industry. Aluminum, on the other hand, has a lower melting point, making it more suitable for applications that require good thermal conductivity, like heat exchangers and electrical wiring. Furthermore, titanium has superior resistance to corrosion compared to aluminum. While aluminum is known for its excellent corrosion resistance, titanium surpasses it in terms of durability, especially in highly aggressive environments, such as saltwater or chemical exposure. This property makes titanium a preferred choice for marine applications, offshore structures, and chemical processing equipment. In summary, aluminum coils and titanium are both valuable non-ferrous metals with unique properties and applications. Aluminum is widely used due to its affordability, availability, and good strength-to-weight ratio, while titanium offers exceptional strength, high-temperature resistance, and superior corrosion resistance at a higher cost. Understanding their differences allows industries to choose the most suitable metal for their specific needs and requirements.

- Q:What are the potential applications of coil-brushed aluminum coils?

- Coil-brushed aluminum coils have a wide range of potential applications due to their unique properties. Here are some of the potential applications: 1. Architectural: Coil-brushed aluminum coils can be used in architectural projects such as building facades, roofing, cladding, and decorative elements. The brushed finish adds a sophisticated and modern look to the structures. 2. Interior Design: These coils can be utilized in interior design applications like wall paneling, ceiling tiles, partition screens, and decorative accents. The brushed texture provides a sleek and stylish appearance, making them suitable for residential, commercial, and hospitality settings. 3. Furniture: Coil-brushed aluminum coils can be incorporated into furniture designs, including tables, chairs, shelves, and cabinets. The brushed finish adds a contemporary touch to the furniture pieces, making them suitable for modern and minimalist styles. 4. Automotive: The lightweight and corrosion-resistant nature of aluminum make it an ideal material for automotive applications. Coil-brushed aluminum can be used in the manufacturing of interior trim, dashboards, door panels, and other decorative components in cars, trucks, and motorcycles. 5. Electronics: With its excellent conductivity and heat dissipation properties, coil-brushed aluminum can be used in the production of electronic devices such as smartphones, laptops, and tablets. The brushed finish adds a premium feel to these products. 6. Signage and Branding: Coil-brushed aluminum coils can be used in the manufacturing of signage and branding elements. The brushed texture enhances the visibility and aesthetics of the signs, making them stand out and convey a sense of quality and professionalism. 7. Kitchenware and Appliances: The durability, heat resistance, and easy cleaning properties of aluminum make it a popular choice for kitchenware and appliances. Coil-brushed aluminum can be used to produce cookware, bakeware, kitchen utensils, and appliance panels, providing a sleek and modern look to these products. 8. Packaging and Labeling: Coil-brushed aluminum coils can be utilized in the production of packaging and labeling materials. The brushed finish adds an elegant touch to product packaging, making it visually appealing and attractive to consumers. Overall, the potential applications of coil-brushed aluminum coils are vast, ranging from architectural and interior design projects to automotive, electronics, kitchenware, signage, and packaging industries. Their unique properties make them a versatile and desirable material for various applications.

- Q:What are the potential applications of laminated aluminum coils?

- Laminated aluminum coils have a wide range of potential applications. They can be used in industries such as electrical, automotive, aerospace, and construction. Some specific applications include electrical transformers, heat exchangers, automotive radiators, air conditioning systems, and architectural facades. The lamination process enhances the durability, heat and corrosion resistance, and electrical conductivity of the coils, making them suitable for various demanding environments and applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1100 Temper H18 0.5mm 0.8m 1mm Thickness Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords