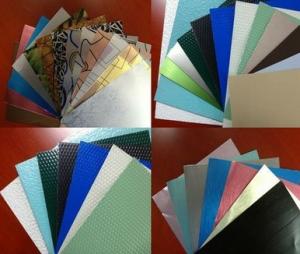

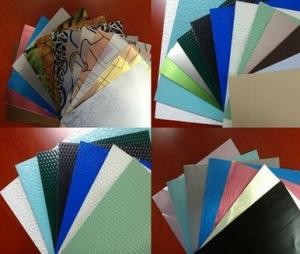

1100 3003 3105 Color Coated Aluminum Sheet/Coil use for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. specification of aluminum sheet / coil

Division | Thickness(m/m) | Width(m/m) | Note |

Coil | 0.2~5.0mm | Max1850mm | Inside diameter 505mm, Outside diameter Max 1,300mm |

Sheet | 0.2~200mm | 160-1850mm | Length Max6000mm |

Circle | 0.5~4.8mm | 160~1000mm | diameter |

Length of aluminum sheet : popular length 1500mm-6000mm ( special length can be produced as your requirement )

Alloy Grade : 1050,1060,1100,3003,3004,3005,3105,5005,5052,5083,5754,6061,6063,etc.

Temper : H12,H44,H16,H18,H22,H24,H26,H32,H34,etc.

2. Application & Feature of aluminum sheet / coil

Division | Alloy | Application | Feature |

1000 SERIES | 1050 1060 1070 1200 | Utensil, decoration, Reflecting plate, printing plate, heatproof plate, cookware | -Easy to process and weld, resistant to rust, high conductibility of electricity and heat, low strength

|

3000 SERIES | 3003 3005 3105 | Utensil(F/P, inside of rice cooker), aluminum can, material for interior and exterior of building,chemical equipment Cellular Phone | 20% higher strength than the 1100 series, easily welded and brazed, good antirust ability Non-heat treatable |

5000 SERIES | 5083 5052 5754 5A05 | Ship board heatproof apparatus, material for interior and exterior of building, Parts of Electronic tools Automobile Components: | -Excellent corrosion resistance andweld ability together with Easy to process and weld and superior hardness &heatproof Can be anodized for increased corrosion resistance |

6000 SERIES | 6061 6063 | IT equipment & facility, Mould material, motor material, automatic line, machine & plant etc. | -Easy to process , good corrosion resistance, high toughness and processed without distortion after heat-treatable, superior surface treatment |

8000 SERIES | 8011 | Kitchen utensils, Bottle cap | -8000 series is durable to process with special alloy. |

Packaging & Delivery

| Packaging Details: | standard export package or as per customer reques |

| Delivery Detail: | 30 days |

- Q:What is the density of 101 aluminum sheets?

- The density of 101 aluminum sheets cannot be determined without knowing the dimensions and weight of each individual sheet.

- Q:What are the different methods of surface preparation for adhesive bonding of aluminum sheet?

- There are several different methods of surface preparation for adhesive bonding of aluminum sheet. These methods include mechanical abrasion, chemical etching, and surface treatments such as anodizing or conversion coating. Mechanical abrasion involves roughening the surface of the aluminum sheet using sandpaper or other abrasive materials to improve adhesion. Chemical etching involves using acid or alkaline solutions to create a textured surface on the aluminum sheet. Surface treatments such as anodizing or conversion coating involve applying a protective layer or coating to the aluminum sheet to enhance adhesion. Ultimately, the choice of surface preparation method depends on the specific requirements of the adhesive bonding process and the type of adhesive being used.

- Q:How does the surface finish of aluminum sheet affect its cleaning requirements?

- The cleaning requirements of aluminum sheet are significantly influenced by its surface finish. Various surface finishes, such as mill finish, brushed finish, or anodized finish, can impact how dirt, grime, and other contaminants adhere to the surface. Smooth and polished surface finishes like brushed or anodized are generally more resistant to dirt and stains, making them simpler to clean. These finishes have a lower surface roughness, resulting in fewer areas for dirt particles to stick to. As a result, they can be effectively cleaned using gentle cleaning solutions or even just water and a soft cloth. Conversely, aluminum sheets with a mill finish or a rougher surface may require more rigorous cleaning methods. The higher surface roughness of these finishes can create more areas for dirt and grime to become trapped, making it more difficult to remove them with basic cleaning techniques. In such cases, more aggressive cleaning solutions or abrasive cleaning tools may be necessary to eliminate stubborn stains or dirt particles. It should be noted that the specific cleaning requirements for aluminum sheet also depend on the type and severity of the contaminants present. For example, if the aluminum sheet comes into contact with harsh chemicals or corrosive substances, special cleaning methods may be needed to ensure complete removal and prevent any potential damage. In conclusion, the surface finish of aluminum sheet directly affects the cleaning requirements. Smoother and polished finishes are generally easier to clean due to their lower surface roughness, while rougher finishes may require more rigorous cleaning methods. Understanding the surface finish of aluminum sheet is crucial in determining the most suitable cleaning techniques to maintain its appearance and functionality.

- Q:Need to polish some small aluminum tubing, preferably to chrome like shine. What tools do I need? Thinking about buying 6 bench grinder, buffing? wheels and polish compound... Does it sound about right?

- Aluminum oxidizes almost instantly, so it is never going to keep a good shine. You can send it to a plating shop and they will anodize it, which means a permanent oxidized layer and that may or may not retain some shine but at least it won't ever change much. (But it is easily stained.) Consider plating some other metal on the surface. You will need advice from a plating shop about that. Maybe you could use chrome plated water pipe? That would be cheaper than a custom job.

- Q:Can aluminum sheets be used for air ducts?

- Yes, aluminum sheets can be used for air ducts. Aluminum is a commonly used material for air ducts due to its lightweight and durable properties. It is resistant to corrosion, which makes it a suitable choice for HVAC systems. Aluminum sheets are often used to fabricate air ducts as they can be easily bent and shaped to fit the required dimensions. Additionally, aluminum has good thermal conductivity, allowing for efficient heat transfer within the ducts. Overall, using aluminum sheets for air ducts is a practical and effective choice.

- Q:combines with oxygen with an atomic weight of 16, to form the compound aluminum oxide, how much oxygen would be required to react completely with 54g of aluminum?

- aluminum oxide is Al2O3 , or 2 part Al to 3 part O. 27 grams Al2 *2 / 54 grams Al available = 16 grams of O * 3 / X grams of O solve for X: X = 48 grams of oxygen needed next guy is right....the formula for aluminum oxide is Al2O3..sorry...I readjusted the formula above to show the change

- Q:Can aluminum sheet be used for aircraft skin panels?

- Yes, aluminum sheet can be used for aircraft skin panels. In fact, aluminum is the most commonly used material for aircraft skin panels due to its favorable properties. Aluminum is lightweight, strong, and resistant to corrosion, making it an ideal choice for constructing aircraft. Additionally, aluminum is easily formable, allowing it to be shaped into the desired contours and curves required for aircraft design. It also has good heat conductivity, which helps to dissipate heat generated during flight. Overall, aluminum sheet is a reliable and efficient material for aircraft skin panels.

- Q:Are aluminum sheets resistant to staining?

- Yes, aluminum sheets are resistant to staining. Aluminum has a natural oxide layer that forms on its surface when exposed to air. This oxide layer acts as a protective barrier, preventing staining and corrosion. However, it is important to note that prolonged exposure to certain chemicals or acidic substances can still cause discoloration or staining on aluminum sheets. Regular cleaning and maintenance are recommended to preserve the appearance and longevity of aluminum sheets.

- Q:a dream I had where the carbon element was extracted from aluminum and ploished it became transparent, it was bendable and you could puncher it with out breaking it ?

- Aluminium is an element! Elements are pure substances, therefore aluminium doesn't contain any carbon. What do you mean?

- Q:I need some aluminum sheets for an art project. I'm not sure where to find such a thing, though. I've looked at Home Depot briefly and aluminum flashing is the closest thing I've found. Flashing comes in a roll and is just a bit too thin. I need flat sheets of aluminum that are somewhat stiff, but not more than, say, 1/4 thick. Are there any stores that sell such things? A larger sheet would be fine if I could either get it cut at the store or find some way to cut it to the size I want. How do you cut aluminum, anyway? Any suggestions are greatly appreciated!

- A local welding shop will have the sheets you need, and is equipped to cut it to size for you.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1100 3003 3105 Color Coated Aluminum Sheet/Coil use for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords