10W CNBM Polycrystalline Silicon Panel for Home Using

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 1000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

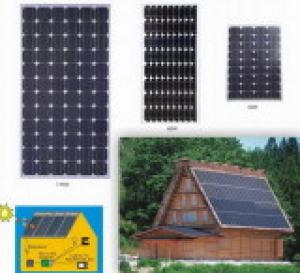

10W CNBM Polycrystalline Silicon Panel for Home Using

Production description

close-packed rectangular multi-junction (MJ) cells are preferably used in solar panels on spacecraft, as they offer the highest ratio of generated power per kilogram lifted into space. MJ-cells are compound semiconductors and made of gallium arsenide (GaAs) and other semiconductor materials. Another emerging PV technology using MJ-cells is concentrator photovoltaics (CPV).

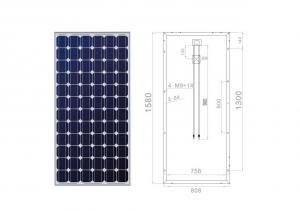

A photovoltaic (in short PV) module is a packaged, connected assembly of typically 6×10 solar cells. Solar PV panels constitute the solar array of a photovoltaic system that generates and supplies solar electricity in commercial and residential applications. Each module is rated by its DC output power under standard test conditions, and typically ranges from 100 to 365 watts.

Feature

1.High conversion efficiencies resulting in superior power output performance.

2.Outstanding power output even in low light or high temperature conditions

3.Optimized design for ease of soldering and lamination

Physical characteristic

1. Rigorous quality control meets the highest international standards.

2. High-transmissivity low-iron tempered glass, strong aluminium frame.

3. Using UV-resistant silicon.

4. IS09001/14001/CE/TUV/UL

packaging

26 pcs in one palllets, 24pcs in one boxs

- Q:Solar panels would change the world if they were widely available to us especially cheap, it will be worth it in the long end. Money would be saved like housands a year per person on utility costs.

- Yes, solar panels could change the world if they were especially cheap--but they're not and may not be cheap for many years, if ever. Lots of new technology could change the world but most of it doesn't. The government doesn't have a very good track record of picking winners in the new technology markets; that's something we should probably leave to the venture capitalists to do--with their own money. The money the government spent on solar panels is gone. Racked up as debt that we'll leave to our children and grandchildren to pay off.

- Q:Okay, so I have a science fair coming up soon and I need help with my project. SO - What should I use to demonstrate with the propeller? A toy boat? Plane? And I only have mini solar panels ; so how do I put the solar panels on the toy boat/plane to make the propeller move off of the sun's energy? Thanks. Steps please!

- Solar panels produce electricity. To move the propeller you need mechanical motion. An Electric motor converts from electrical to mechanical power. Most Solar Panels produce DC electricity as do batteries so you need a DC motor that is sized to match the Output of your solar panels. For small temporary projects like this I find that hot melt glue is great to assemble parts. Using a voltage meter you can expose your solar panels to a strong light (or one equal to what you expect during your demonstration) and measure the voltage across the terminals. This may help to size the motor. It depends upon the size of your propeller and how it is made. Your three choices are to use it to power an airplane, to power a boat underwater or to power a boat like an air boat. You might also use the air boat concept to make a car. (air car) The air boat might be the simplest to make but you will need a body of water to demonstrate the concept. The air car doesn't have such a requirement.

- Q:Mono-crystalline or poly-crystalline solar panel?

- All solar photovoltaics drop in efficiencies with higher temperatures but it isn't the 45+ C you have to worry about but rather the heat from the sunlight striking the panels. There are hybrid systems which passes water in pipes attached to the back of the solar panels to cool the panels and preheat the water for solar thermal collectors. The difference between mono-crystalline and poly-crystalline are that mono-crystalline are more efficient and more costly to make.

- Q:how the power output of solar panels fitted to a house can chargenothing on the internet really answers this question, any information will really help..this is for GCSE, i don't really understand the meaning of the question. does it ask how the solar panel egts charged, and how it works? i don't get how you can charge a solar panel and is heat the only way you can produce electricity for it??please answer if you know! much appreciated!!! thank you so so so so so so so much, in advance =)

- Solar panels do NOT get charged, so the question is junk, or you misstated it. Solar panels are used to charge a battery bank, which stores energy for times when there is no sun. Then energy from the batteries is used, via an inverter, to power appliances in the house. OR do you mean how the power output of solar panels can CHANGE? In that case, they change when the sun moves, such as behind a cloud, or just changes angle in the sky, or goes out.

- Q:Are solar panels a good investment?

- Yes, solar panels are a good investment. They offer long-term financial benefits through reduced electricity bills, potential tax incentives, and increased property value. Additionally, they contribute to a cleaner environment by reducing carbon emissions and dependence on fossil fuels.

- Q:I want to make 2V 4.5A solar panel to charge my battery used in my RC car project. I just like to know how should I amplify the current for 4.5A. I need the total circuit diagram. Can anyone help me. Please. I need some affordable methods please.

- The simplest way to use these panels is simply to connect the panel to your battery, with a diode in series to prevent the battery from discharging through the panel (no sunlight condition). Just connect the battery for the required charge time then disconnect it. Full sun is required, no shadows on the solar panel! ---------- .

- Q:Can solar panels be installed on rooftop gardens or green roofs?

- Yes, solar panels can be installed on rooftop gardens or green roofs. In fact, these types of roofs provide an ideal space for solar panel installation as they often have ample sunlight exposure and can help optimize energy efficiency of the building. Additionally, solar panels on rooftop gardens or green roofs can contribute to a more sustainable and eco-friendly environment by combining renewable energy generation with green infrastructure.

- Q:Ok, so my homework was to research and write about how solar panels and solar furnaces work and about their construction. We didn't even take one lesson on it in class and we are not allowed to copy and paste much and have to keep it simple wtf? Its soo annoying as we have hardly took it in class. Please can someone help.

- Well solar panels conduct electricity from the suns waves and turns it into dc current then it is either put into a grid tie inverter to change it to AC and it makes you meter go backwards instead of forwards. or if its not a grid tie inverter it is just put into batteries as dc then changed into AC from the inverter and then used for household appliances. nothing really does run on DC that is why it has to be changed. and for solar furnaces if you mean a water heater that works by a substance here in Pa its antifreeze is heated up by the sun in the panel it is in a continous loop and that is what gets heated up the water then flows over tow of the tube that contains what ever substance such as antifreeze and heats the water.were the water and the tube that changes the water from cold to hot is called the heat exchanger. the substance is actually get heated first then the water. solar heating for water accounts for 29% of water heating in the us. Now if you mean solar furnace as in passive solar thats completely different because here in Pa if we want it our houses have to face to south to get the suns rays. (alot more windows) and there is a cement slab placed only on the south side of the house and it has insulation covering it. There is a certain type of glass that is used for this that will allow the suns rays to come in and let the heat in for the summer and also for the winter. the main place for that would mostly be the first floor of the house due to the height of the windows and the angle of the sun(pa in the summer is 73 degrees and in the winter its 27 degrees) thats when the second floor would be ok to heat the rooms. Hopefully i helped and i explained it in a way that you can understand.

- Q:Can solar panels be integrated into buildings?

- Yes, solar panels can be integrated into buildings through various methods such as rooftop installations, solar facades, and building-integrated photovoltaics (BIPV). These approaches allow for a seamless integration of solar panels into the building's structure, providing renewable energy generation without compromising the overall aesthetics or functionality of the building.

- Q:how big of an solar panel do i need to power/charge my laptop?would one from canadian tire sell the right one?

- Yes. Basically, here's what you need (I'm keeping this general on purpose): The panels themselves -- how large an area depends on average power consumption and how much power you can get on average. That, in turn , depends on climate. You'd need more in Seattle than Tuscon, for example. I'd guess something in the neighborhod of 0 square feet. Depends also on haow many gadgets (printers, etc.) you have. You'll need a power storage system. Lithium gives you the best poser density (of off-the-shelf stuff) but an ordinary car battery works well and is reliable. And, of course, a control system to manage the power generation/storage/use so everything works together without that annoying smell that tells you you just cooked a few hundred bucks worth of equuipment! :)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

10W CNBM Polycrystalline Silicon Panel for Home Using

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 1000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords