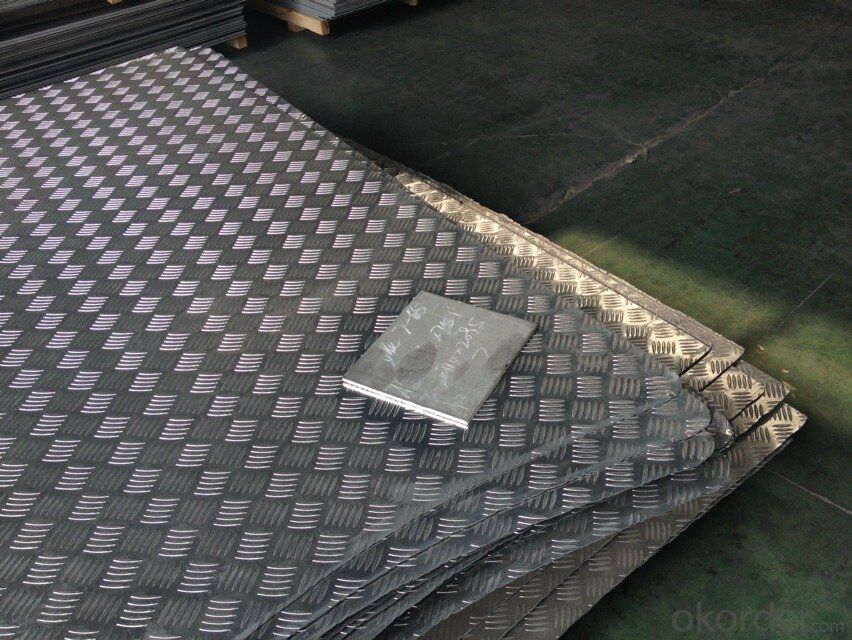

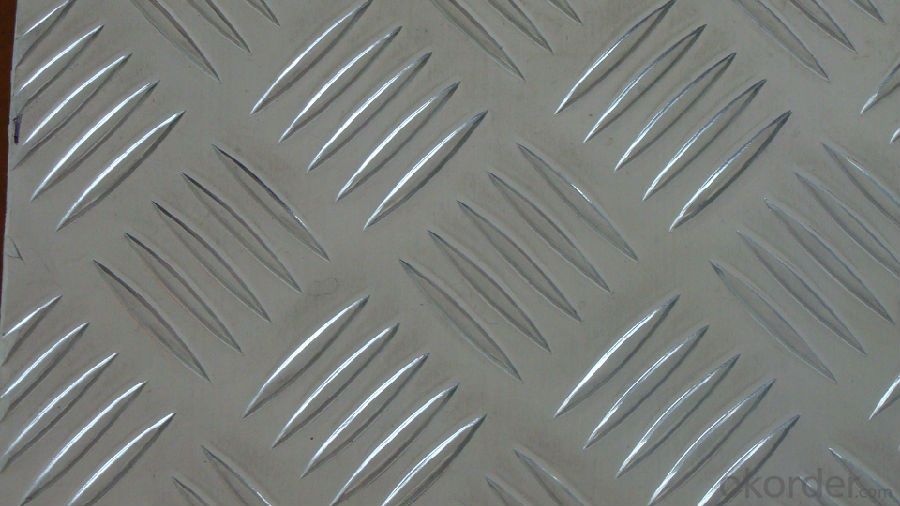

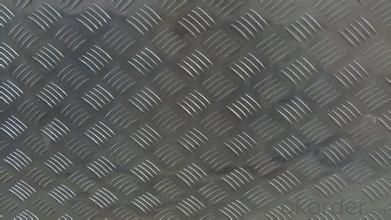

1050 1060 1100 3003 5052 5 Bar Aluminum Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

aluminum chequered plate are widely usd for bus, cars and shipping vessel as the floor....

Aluminum tread plate is also called anti-slide aluminum sheet which is widely used in manufacturing vehicles, ships, washing machines, refrigerator shell, etc.

Specification:

Denomination | Final application | Temper | Thickness | Width | Inner diameter | Outside |

diameter | ||||||

Semi-rigid container foil | Food container applied in aviation | 3003/8011--H22,H24,O | 0.02-0.09 | 300-600 | 76/152 | 100-600 |

Household foils | Soft packing in household | 8011--O | 0.01-0.02 | 200-700 | 76 | 200-800 |

Pharmaceutical foil | Packing for Blister foil | 8011--H18 | 0.020-0.025 | 400-1100 | 76/152 | 760 |

Cable foil | Wraping for cable | 1100/8011,O | 0.15-0.05 | 500-800 | 76 | 760 |

Aluminum fin stock | Hear exchanger and condensator for A/C | 8011--H24,O | 0.1-0.13 | 400-1000 | 152 | 760 |

Cigarette foil | Packing for cigarette | 1235--O | 0.0065-0.007 | 460,520 | 76 | 400 |

Foil for hot seal | Hot seal cover for acidophilus milk and other beverage | 1235/8011--O | 0.02-0.038 | 400-600 | 76 | 760 |

Thick foil for deep processing | Seal for beer bottle | 1145/8011,O | 0.0115 | 300-600 | 76/152 | 400/760 |

Shield for video cable | 0.01-0.012 | 500 | 76 | 400 | ||

Aluminum adhesive tape | 0.2-0.06 | 300-600 | 76/152 | 400/760 | ||

Thin foil for deep-processing | Foil with thickness less than ten micron applied in surface of packing materials | 8011/1235--O | 0.0065-0.007 | 460-1000 | 76 | 400 |

Foil for automobile radiator | Water tank radiator in automobile | 8011/1050--H18 | 0.08-0.10 | 140-600 | 76 | 760 |

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q:I've heard twice in the past 2 days on ESPN that they think Aluminum bats are dangerous. I disagree with this cause if they were dangerous why would they allow them to use them in college and high school. Isnt that what the BESR certification mean that the bat is safe that the ball isnt going to come off at super high speeds. i just wanted to get your opinion.

- Yes I heard this also and let me tell you something the wooden bats are also dangerous. I hate hitting a ball and then I get stung and that hurts. I like the aluminum bats better, so they should just keep them on the market because they are not so much dangerous then the wooden one's.

- Q:Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation to some extent. While aluminum is not the best material for soundproofing compared to others like rubber or foam, it can still provide some level of sound insulation when used correctly. Aluminum sheets can be installed as a barrier or partition in walls, ceilings, floors, or other surfaces to reduce the transmission of sound waves. However, it is important to note that additional soundproofing materials or techniques might be necessary to achieve optimal results.

- Q:What is the modulus of elasticity for aluminum sheets?

- The modulus of elasticity for aluminum sheets, also known as Young's modulus, is typically around 69 GPa (gigapascals) or 10 million pounds per square inch (psi). This value represents the measure of the stiffness or rigidity of the material. However, it is important to note that the modulus of elasticity can vary slightly depending on the specific alloy composition and tempering of the aluminum sheet.

- Q:What is the typical yield strength of aluminum sheets?

- The typical yield strength of aluminum sheets can vary depending on the specific alloy and temper, but it typically ranges from 15,000 to 40,000 psi (pounds per square inch).

- Q:What are the different types of surface treatments available for anodized aluminum sheets?

- For anodized aluminum sheets, there exists a range of surface treatments that can enhance the appearance, durability, and functionality of the material. One option is the brushed finish, which involves using abrasive materials to create parallel lines on the sheet. This technique gives the aluminum a matte appearance and effectively conceals scratches and fingerprints. Another treatment is the mirror finish, achieved through polishing the sheet to create a high gloss, mirror-like reflection. This finish is commonly used for decorative purposes and provides a sleek and modern look. Etching is a process in which chemicals or abrasives are used to remove a thin layer of the anodized coating, creating a textured or patterned design on the sheet. This technique allows for customization and unique aesthetics. Powder coating is a popular treatment in which a dry powder is electrostatically applied to the anodized aluminum sheet and then cured under heat. This creates a durable and customizable coating in terms of color, texture, and finish. For a smooth, brushed appearance, satin finish involves sanding the aluminum sheet with fine grit sandpaper. This finish gives the surface a subdued and elegant look. Mechanical finishes encompass various techniques like polishing, buffing, or grinding to achieve different textures and finishes. The final result can range from smooth and glossy to rugged and textured, depending on the desired effect. Chemical treatments such as anodizing, chromating, or chemical brightening can enhance the corrosion resistance, color, and overall appearance of the aluminum sheet. They also improve the adhesion of paints or adhesives to the surface. It is important to consider that the availability of these surface treatments may vary depending on the manufacturer and specific requirements. Consulting with the supplier or manufacturer is recommended to determine the most suitable treatment for your application.

- Q:What are the different thicknesses available for aluminum sheet?

- Aluminum sheets are available in a variety of thicknesses, ranging from extremely thin to thick. The thickness of aluminum sheets is measured in gauge or millimeters (mm), with each gauge representing a specific thickness. The most common gauges for aluminum sheets include 22, 24, 26, 28, 30, and 32. These gauges correspond to thicknesses ranging from 0.0254 mm to 0.635 mm. Additionally, aluminum sheets can be found in thicker gauges, such as 16 gauge (1.29 mm) or even thicker for specialized applications. The choice of thickness depends on the intended use of the aluminum sheet, with thinner sheets often being used for lightweight applications like electronics or packaging, while thicker sheets are preferred for structural or industrial purposes.

- Q:Are aluminum sheets suitable for use in marine or saltwater environments?

- Aluminum sheets are indeed appropriate for utilization in marine or saltwater settings. Aluminum boasts exceptional resistance to corrosion and is renowned for its capacity to endure the challenging conditions present in marine environments. In contrast to numerous other metals, when aluminum is exposed to oxygen, it forms a shielding oxide layer on its surface, which aids in thwarting further corrosion. This oxide layer serves as a barrier, shielding the underlying metal from saltwater and other detrimental elements. Furthermore, aluminum is both lightweight and robust, rendering it an optimal selection for marine applications that prioritize weight reduction. It is commonly employed in the construction of boats, ships, offshore structures, and various other marine apparatus.

- Q:Can aluminum sheets be polished?

- Yes, aluminum sheets can be polished. Polishing aluminum sheets involves smoothing the surface and creating a reflective finish using abrasive materials or polishing compounds.

- Q:Are aluminum sheets suitable for signage?

- Signage can greatly benefit from the use of aluminum sheets. This material is known for its versatility and numerous advantages when it comes to signage applications. With its lightweight nature, durability, and resistance to corrosion, aluminum is an excellent choice for both indoor and outdoor signage. Regardless of weather conditions, be it rain, snow, or intense UV exposure, aluminum sheets will not deteriorate or fade. Furthermore, aluminum sheets are easy to work with, providing a wide range of customization options such as embossing, engraving, and digital printing. Not only are they cost-effective, but they also have a long lifespan, ensuring that signage remains in top-notch condition for extended periods. Ultimately, due to their durability, versatility, and aesthetic appeal, aluminum sheets are a preferred choice for signage.

- Q:Can aluminum sheets be used for decorative panels?

- Aluminum sheets are indeed suitable for decorative panels. Being a lightweight and versatile material, aluminum can be easily shaped, cut, and molded into various designs and patterns. Its sleek and modern appearance makes it a popular option for decorative purposes in both residential and commercial settings. Aluminum panels have a wide range of applications, including wall cladding, ceiling panels, room dividers, signage, and more. Moreover, aluminum is resistant to corrosion and weathering, making it suitable for both indoor and outdoor use. Additionally, aluminum panels can be personalized with different finishes, such as powder coating or anodizing, to enhance their visual appeal. In conclusion, aluminum sheets are an excellent choice for creating decorative panels due to their pleasing aesthetics, durability, and adaptability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1050 1060 1100 3003 5052 5 Bar Aluminum Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords