1050 1060 1100 1200 Alloy Color Coated Aluminium Coil 5083

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

1100-H14-DIAMOND EMBOSSED ALUMINUM SHEET

Thickness:1.2mm---4mm,

width:1000mm---1500mm

Product code: 618 a - 33 y titanium matte aluminum plate

Technical parameters

Aluminum alloy/material: 1100

Tensile strength N/was: 115-125

The yield strength of N/was: 150-150

Elongation % : 3 or more

Rainbow degrees: no

Process: light oxidation process

Product description: surface "colored metal silken face" as the main characteristics of the product, completely metal texture, color variety, products can be mild tensile and bending.

Product use: can be used to directly shape stamping, screen printing, thermal transfer two composite process, etc.Used in architectural decoration, household appliances, switch panel, auto parts, lamps lighting, electronic hardware and other industries.

Supply scope of coil or sheet

Mm thickness specification: 0.4 1

Maximum width mm: 1250

The tolerance range

Mm thickness: 0.02 mm

The width of the mm: 2 -

Mm length: 2 -

Actual weight kg: plus or minus 2

Protective film

Protective film on the surface of the aluminum quality assurance period for six months, aluminum is kept dry and ventilated, avoid heat and direct sunlight.If the aluminium material stored in high temperature or direct sunlight can cause protective film, or unable to tear in addition to wait for a phenomenon.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

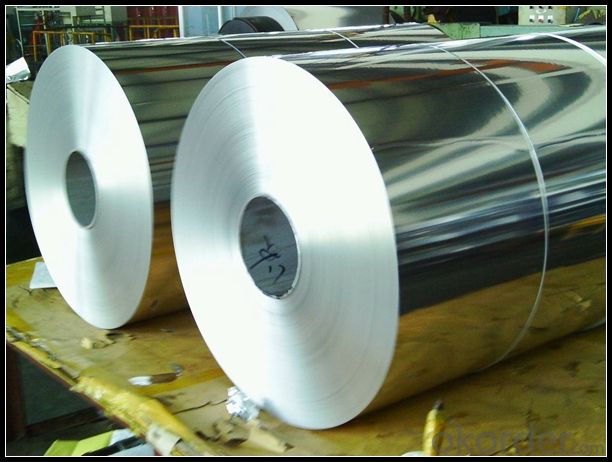

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q:How do aluminum sheets perform in extreme weather conditions?

- Aluminum sheets are renowned for their exceptional performance in extreme weather conditions, as they possess inherent properties that render them highly resistant to corrosion and capable of enduring harsh environmental elements like rain, snow, and extreme temperature fluctuations. When confronted with hot weather, aluminum sheets possess the ability to reflect sunlight and dispel heat, thereby averting any warping or deformation. This characteristic renders them suitable for utilization in regions characterized by high temperatures or direct exposure to sunlight. Similarly, in cold weather, aluminum sheets retain their strength and do not become brittle, making them dependable in freezing temperatures or regions prone to heavy snowfall. With a low coefficient of thermal expansion, they can withstand contraction and expansion without any detrimental effects such as cracking or damage. Moreover, aluminum sheets exhibit excellent resistance to moisture, which safeguards them against rusting or corroding when exposed to rain or high levels of humidity. This quality makes them an ideal choice for employment in coastal areas or regions with substantial rainfall. Additionally, aluminum sheets possess the advantage of being lightweight yet durable, enabling them to withstand high winds and severe storms without compromising their structural integrity. This quality positions them as the preferred option for applications such as roofing, siding, and outdoor signage in areas susceptible to hurricanes or strong winds. All in all, aluminum sheets display remarkable performance in extreme weather conditions, which establishes them as a reliable and versatile material for various outdoor applications.

- Q:What are the different methods of surface engraving aluminum sheets?

- Aluminum sheets can be surface engraved using various methods, each with its own unique advantages and suitability for different applications. One method is mechanical engraving, which involves physically removing material from the aluminum sheet using a rotating cutting tool like a milling machine or a router. This precise and versatile technique allows for intricate designs and deep engravings, making it commonly used for signage, branding, and decorative purposes. Another method is laser engraving, a modern and highly precise technique that uses a laser beam to vaporize or melt the surface of the aluminum sheet, creating a permanent mark. With great control over the depth, speed, and intensity of the engraving, laser engraving produces detailed and accurate results. It finds wide application in industries like aerospace, automotive, and electronics for part identification, serial numbers, and barcodes. Chemical etching, also known as chemical milling or photochemical machining, is a process where the aluminum sheet is coated with a photosensitive mask and exposed to UV light through a stencil or artwork. The exposed areas are then chemically etched to create the desired design. Chemical etching offers high precision, repeatability, and the ability to engrave thin lines or complex patterns. It is often used in electronic components, nameplates, and decorative applications. Diamond drag engraving involves using a diamond-tipped stylus to scratch or indent the surface of the aluminum sheet, creating the engraving. This method is commonly employed for industrial applications like part identification and serial numbering, as well as for creating durable and long-lasting markings on aluminum sheets. Lastly, rotary engraving utilizes a rotating cutting tool to remove material from the aluminum sheet, similar to mechanical engraving. However, it is typically used for larger and thicker aluminum sheets and finds application in industrial settings for marking, labeling, and identification purposes. Choosing the appropriate engraving method for aluminum sheets depends on factors such as the desired design, level of detail, durability requirements, and the intended use of the engraved product. Each method offers its own advantages and suitability for different applications.

- Q:What is the cost of aluminum sheets compared to other metals?

- The cost of aluminum sheets is generally lower compared to other metals such as stainless steel or copper. Aluminum is a widely available and abundant material, which contributes to its relatively affordable price in comparison to other metals.

- Q:Can aluminum sheets handle high temperatures?

- Yes, aluminum sheets can handle high temperatures. Aluminum has a high melting point of 1220°F (660°C) and excellent heat transfer properties, making it suitable for various applications that involve exposure to high temperatures.

- Q:Aluminum or steel bike frame cost more???...which one cost the most usually???

- Good quality steel frames are almost always more expensive than aluminum. There are a couple of reasons for this... 1) Aluminum is always welded. This takes much less effort and time than a fine brazed steel unit; 2) High quality steel tubing is very expensive compared to aluminum due to the thin walls and sometimes exotic alloying materials; 3) Aluminum is one of the most common elements on the planet. Common steel alloys have harder-to-obtain elements such as molybdneum, manganese, and other rare metals. 4) Although many aluminums require post weld processing it takes little or no labor to complete it while a high quality steel frame responds beautifully to hand work. 5) A good steel frame is simply harder to find nowadays. I know that this goes beyond the scope of your question, but keep in mind that regardless of the aluminum alloy it all weighs the same; regardless of the steel alloy it all weighs the same. The difference in weight comes from modifying the metal mixture, enabling a stronger metal and making of ever-thinner tubes. Kojman47 (below) is WAAY off in his interpretation of materials. There are steel frames that rival the weight and strength of titanium which is often 1/2 the weight of aluminum. There is no such thing as cromolly. The correct name (if I may) is Chrome Molybdneum, abbreviated as CrMo, often called Chrome Moly. Cromoly or cromolly or cromo doesn't give proper respect to the alloy OR to the frame. CrMo (cromolly in Kojmans eyes) is steel.

- Q:Are the aluminum sheets suitable for manufacturing traffic signs?

- Yes, aluminum sheets are suitable for manufacturing traffic signs. Aluminum is a popular choice for traffic signs due to its durability, lightweight nature, and resistance to corrosion. These qualities make it ideal for withstanding various weather conditions and ensuring a long lifespan for the traffic signs. Additionally, aluminum sheets can be easily shaped into different sizes and designs, allowing for the creation of custom traffic signs. Overall, the use of aluminum sheets in manufacturing traffic signs is a reliable and efficient choice.

- Q:does anyone know how aluminum recycling works in term of redox reaction ( oxidizing, reduced, oxidizing agent, reducing agent?). how is that relate to the process of electrochemistry?

- Aluminum recycling is done by just melting the cans back into molten metal. There are reactions, but those deal with the impurities, not the aluminum. See the reference.

- Q:Everyone said that the pre roll coated aluminum plate, what is pre roll coating?

- Beforehand, beforehand, mean,Roll coating is a paint coating process, relative to spraying, such as powder, wall coating, coating or roller coatingThe coating is applied to the surface of the aluminum sheet by a roller or steel roller. Roll coating

- Q:How does aluminum sheet perform in outdoor applications?

- Aluminum sheet performs exceptionally well in outdoor applications due to its inherent corrosion resistance and durability. It is highly resistant to rust and can withstand exposure to harsh weather conditions, making it ideal for outdoor structures, signage, and cladding. Additionally, aluminum sheets can be coated or painted to enhance their weather resistance and aesthetic appeal. Overall, aluminum sheet is a reliable and long-lasting material for various outdoor applications.

- Q:What is the weight of a standard aluminum sheet?

- The weight of a standard aluminum sheet can vary depending on its dimensions and thickness. However, on average, aluminum sheets typically weigh around 2.7 grams per cubic centimeter. To determine the weight of a specific aluminum sheet, you would need to know the dimensions (length, width, and thickness) and multiply them to obtain the sheet's volume. Then, you can multiply the volume by the density of aluminum (2.7 g/cm³) to calculate the weight in grams.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1050 1060 1100 1200 Alloy Color Coated Aluminium Coil 5083

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords