1000 Series Aluminium Sheet And Aluminium Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

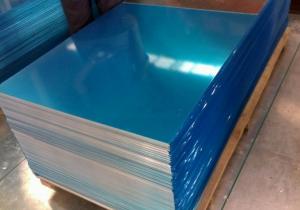

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q:How do I prevent corrosion on aluminum sheets?

- There are several ways to prevent corrosion on aluminum sheets. Firstly, you can apply a protective coating such as paint or powder coating to create a barrier between the aluminum and the surrounding environment. Additionally, you can use anodizing, which involves creating a controlled oxidation layer on the surface of the aluminum to enhance its resistance to corrosion. Regular cleaning and maintenance are also important to remove any corrosive substances and keep the aluminum sheets in good condition.

- Q:What will affect the performance of the aluminum ingot in the process of casting?

- We all know that in 50s our technical standards are from the former Soviet Union, "A00" is the national standard in the Soviet Russian brand, "A" is the Russian alphabet, rather than English "A" word, nor the Chinese phonetic alphabet "A" and the international community, "said standard aluminum is more precise. Standard aluminium is the aluminum ingot containing 99.7% aluminium, which is registered in the London market.

- Q:What is aluminum sheet?

- Aluminum sheet, an often employed material in different industries and applications, refers to a flat and thin piece of aluminum. Its production involves the rolling of aluminum ingots between large rollers until the desired thickness is achieved. Lightweight and durable, aluminum sheets possess exceptional resistance to corrosion, rendering them suitable for a wide array of purposes. In the construction sector, they find common use in roofing, siding, and insulation. Furthermore, their application extends to industries such as automotive, aerospace, packaging, and electrical due to their high conductivity and ease of molding into various shapes. In conclusion, aluminum sheets are highly coveted for their strength, flexibility, and aesthetic appeal, making them an incredibly versatile material.

- Q:How to press multilayer aluminum sheets (aluminum sheet's thickness: 0.2mm) together and keep them inseperate after pressing?

- resistance welding usually overlays two pieces together and presses them, heating them to melting state through current, you can try multiple sheets.

- Q:what's the difference between the knocking voice of aluminum sheet and stainless steel?

- The voice of aluminum sheet is toneless, and the voice of stanless steel is more crisp.

- Q:aluminum is produced by breaking down the compound...

- Bauxite is the most important aluminum ore. It consists largely of the minerals gibbsite Al(OH)3, boehmite γ-AlO(OH), and diaspore α-AlO(OH), together with the iron oxides goethite and hematite, the clay mineral kaolinite and small amounts of anatase TiO2. You have an unusual way of asking that question. Aluminum is an element and cannot be broken down accept to sub-atomic particles.

- Q:As for graphite and aluminum sheet, which one has a better thermal conductivity?

- Aluminum sheet has a better thermal conductivity, because metal is good conductor of heat, graphite is n't metal.

- Q:Are the aluminum sheets suitable for manufacturing power distribution panels?

- Yes, aluminum sheets are suitable for manufacturing power distribution panels. Aluminum is a lightweight, durable, and corrosion-resistant material that makes it an ideal choice for various industrial applications, including power distribution panels. Aluminum sheets can withstand high electrical currents while effectively dissipating heat, ensuring the safe and efficient distribution of power. Additionally, aluminum is readily available and cost-effective compared to other materials such as copper. Therefore, aluminum sheets are a suitable choice for manufacturing power distribution panels.

- Q:we have the mass of an aluminum sample =.47g, and the number of atoms in sample =107

- Look up the atomic mass of aluminum on your periodic table, multiply by 107, then divide by .47g?

- Q:What is the typical bend radius for aluminum sheets?

- The typical bend radius for aluminum sheets depends on various factors, such as the alloy, thickness, and temper of the sheet. However, a general guideline for the minimum bend radius for aluminum sheets is typically around 1 to 1.5 times the material thickness. For example, if you have a 1mm thick aluminum sheet, the minimum bend radius would be around 1 to 1.5mm. It is important to note that this is just a general guideline, and the specific bend radius may vary depending on the specific application and requirements. It is advisable to consult with a professional or reference material specifications for precise bend radius recommendations for a specific aluminum sheet.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1000 Series Aluminium Sheet And Aluminium Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords