1000 Series 3000 Series 5000 Series H18/H16/ H24/H28 Zinc Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

1100-H14-DIAMOND EMBOSSED ALUMINUM SHEET

Thickness:1.2mm---4mm,

width:1000mm---1500mm

Product code: 618 a - 33 y titanium matte aluminum plate

Technical parameters

Aluminum alloy/material: 1100

Tensile strength N/was: 115-125

The yield strength of N/was: 150-150

Elongation % : 3 or more

Rainbow degrees: no

Process: light oxidation process

Product description: surface "colored metal silken face" as the main characteristics of the product, completely metal texture, color variety, products can be mild tensile and bending.

Product use: can be used to directly shape stamping, screen printing, thermal transfer two composite process, etc.Used in architectural decoration, household appliances, switch panel, auto parts, lamps lighting, electronic hardware and other industries.

Supply scope of coil or sheet

Mm thickness specification: 0.4 1

Maximum width mm: 1250

The tolerance range

Mm thickness: 0.02 mm

The width of the mm: 2 -

Mm length: 2 -

Actual weight kg: plus or minus 2

Protective film

Protective film on the surface of the aluminum quality assurance period for six months, aluminum is kept dry and ventilated, avoid heat and direct sunlight.If the aluminium material stored in high temperature or direct sunlight can cause protective film, or unable to tear in addition to wait for a phenomenon.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

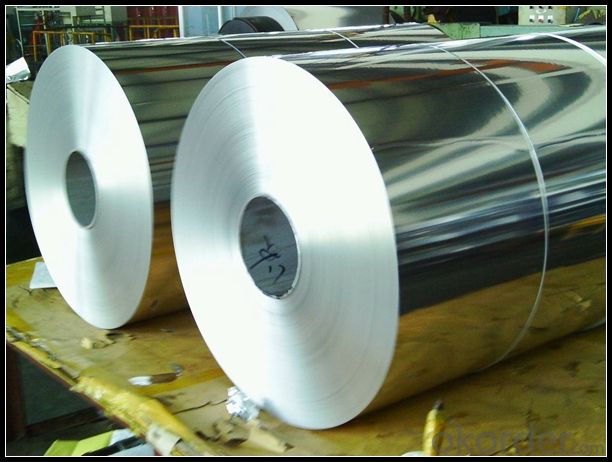

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q:Can you really block thermal imaging with glass or aluminum foil? If not, what can?

- Well, silly! That keeps the space aliens from getting to them! Their brain sucking devices can't penetrate aluminum foil. Seriously, though, it's a redneck attempt to block the direct sun and keep the room from heating up.

- Q:could aluminum sheet be attracted by magnet?

- no, it couldn't.

- Q:I found a baby dish at a yard sale and all it says on the bottom is Lydney Aluminum PRODUCTS FOR BETTER LIVING. It appears old. Thanks. I already checked google.

- lydney appears to be a place in england. they probably get their aluminium there.

- Q:Is plastic or alumium container more harmful to store food in if it does get to the food while heating.

- plastic is more harmful when heated, they release dexoxin which is cancer causing. If you use them in micro ovens, its harmfull. Aluminum is much safer to cook in. It can with stand high temperatures.

- Q:Can aluminum sheets be custom cut to specific sizes?

- Indeed, specific sizes can be achieved through the customization of aluminum sheets. Possessing great versatility, aluminum proves itself as a material that can be effortlessly shaped and cut to meet particular needs. By utilizing appropriate tools and equipment, one can achieve precise cuts on aluminum sheets, regardless of their purpose in industrial, commercial, or personal settings. This adaptability allows for the tailoring of aluminum sheets to suit specific applications, rendering it a favored option across various industries such as construction, automotive, and aerospace. Whether one requires compact or expansive aluminum sheets, they can be conveniently tailored to the precise dimensions necessary, guaranteeing an accurate fit for any given project or application.

- Q:Can aluminum sheets be bent or formed?

- Indeed, it is possible to bend or shape aluminum sheets. Aluminum, being a remarkably malleable and ductile metal, can be effortlessly molded or bent without fracturing. This attribute renders it a favored option for a wide range of purposes, including the production of automotive components, aircraft structures, and household products. Diverse techniques, such as press braking, roll bending, and stretch forming, can be employed to bend or shape aluminum sheets. By utilizing these methodologies, the aluminum sheets can be formed into diverse angles or curves to fulfill precise design prerequisites.

- Q:Are aluminum sheets conductive?

- Yes, aluminum sheets are conductive.

- Q:Are aluminum sheets suitable for laser cutting?

- Yes, aluminum sheets are suitable for laser cutting. Aluminum is a commonly used material in laser cutting due to its excellent reflective properties, high thermal conductivity, and low melting point. These characteristics make it an ideal material to be cut by a laser beam. Laser cutting provides precise and clean cuts on aluminum sheets, allowing for intricate designs and complex shapes to be easily achieved. Additionally, laser cutting of aluminum sheets is a fast and efficient process, offering high productivity and cost-effectiveness.

- Q:How do aluminum sheets compare to other metals in terms of strength?

- Compared to other metals, aluminum sheets typically possess lower strength. Although aluminum is lightweight and exhibits excellent corrosion resistance, it lacks the same level of strength as steel or titanium. In terms of tensile strength and yield strength, aluminum falls short when compared to these metals, rendering it more susceptible to deformation and failure when subjected to heavy loads. Nevertheless, by alloying aluminum with other elements, its strength can be enhanced, allowing certain aluminum alloys to compete with or even surpass the strength of certain other metals. Furthermore, aluminum's strength-to-weight ratio stands as one of its primary advantages, making it the preferred choice in industries where weight reduction is critical, such as aerospace and automotive. All in all, while aluminum may not possess the highest level of strength among metals, its combination of strength, lightweight properties, and corrosion resistance renders it an adaptable material for various applications.

- Q:What's the standard thickness of aluminum sheet?

- the thickness of tobacco aluminum foil and red wine bottle cap is designed according to customers demands and manufacturer has no stated specification.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1000 Series 3000 Series 5000 Series H18/H16/ H24/H28 Zinc Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords