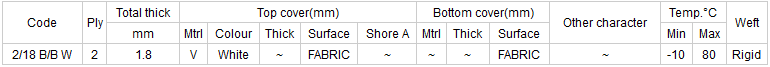

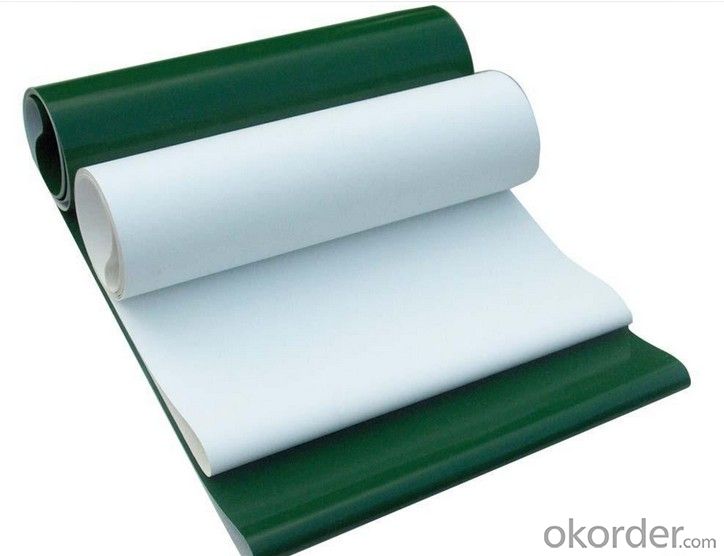

1.8mm Double Sided Polyester PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.8mm Double Sided Polyester PVC Conveyor Belt

PVC Conveyor Belt Features:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

1. Non-Conductive

2. Anti-Static

3. Resistant to fats, chemicals, oil fat and abrasion

4.Color:Apple Green,Petrol Green,Blue,Black,etc

5. Various surfaces with high, medium and low coefficient friction

Thickness: PVC Belting (1~7mm) PU Belting (0.8~4mm)

Width: 200mm ~ 4000mm

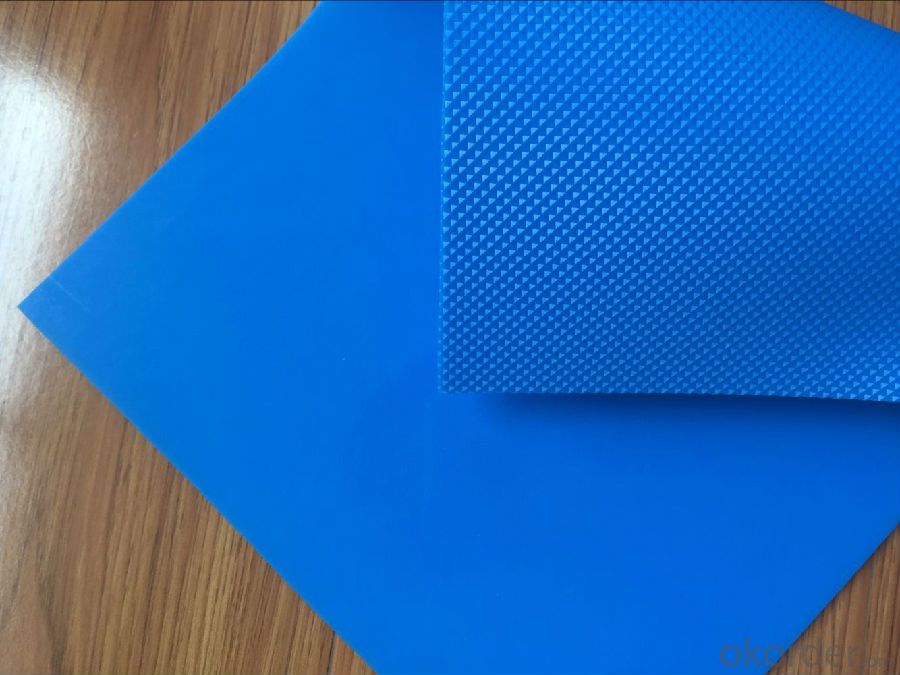

Appearance: Flat surface, diamond pattern, lawn pattern, golf pattern,etc.

Colors: Green, blue, gray, white, black, blue, dark green, transparent,etc.

Subsequent machining technology: It can add baffle, skirt, sponge, guide bar,etc.PVC Conveyor Belt Specifications:

PVC Conveyor Belt Applications

PVC Conveyor belt has a wide range of products which can be applied in different industries, such as: tobacco, food, logistics, post, airport machinery, phamaceuticals, chemistry, electronics, printing, cable pulling, steel wrapping and sports entertainment.

Photos

- Q:Can olive nets be used for both young and mature olive trees?

- Yes, olive nets can be used for both young and mature olive trees. Olive nets are typically used to protect the crop from birds and to collect the fallen olives during harvesting. Both young and mature olive trees can benefit from the use of olive nets to minimize crop damage and facilitate the collection process.

- Q:Is there a specific color olive net that works best?

- No, there is no specific color olive net that works best as the choice of color depends on various factors such as the environment, visibility requirements, and personal preferences.

- Q:Can olive nets be used in regions with high salinity levels in the soil?

- Olive nets can be used in regions with high salinity levels in the soil, as they primarily serve as a protective barrier to catch and collect the falling olives during harvest. However, it is important to note that high salinity levels in the soil can negatively impact the overall health and productivity of olive trees. Therefore, it is recommended to address and mitigate the salinity issue through appropriate soil management practices before relying solely on olive nets.

- Q:How do you repair the plastic surface that scratches?

- Buy a bottle of regular glue, a transparent one, and you can't see it when it is painted dry

- Q:How can lenses be made out of plastic or resin?

- Of course, the resin can be divided into many types, you can do is not transparent lenses, transparency, refractive index and wear resistance have higher requirements, like ordinary glass can do glasses, optical glass must be dedicated to. Although glasses are profiteering products, but the quality of high-grade lenses will be much cheaper than the quality

- Q:Are there any environmental concerns related to the use of olive nets?

- Yes, there are some environmental concerns related to the use of olive nets. The nets, if not managed properly, can trap and harm birds and other wildlife that may become entangled in them. Additionally, the use of nets can also lead to soil erosion and impact the overall ecosystem by altering natural processes such as seed dispersal or the nutrient cycle. However, with proper management practices and the use of eco-friendly alternatives, these concerns can be minimized.

- Q:Can olive nets be used for olive trees in regions with strong winds?

- Yes, olive nets can be used for olive trees in regions with strong winds. Olive nets are specifically designed to protect the olives from birds and pests, but they can also provide some degree of wind protection. While they may not completely shield the trees from strong winds, they can help reduce the impact of the wind on the olives and prevent them from being blown off prematurely. It is still important to consider other measures such as staking or bracing the trees to ensure their stability in areas with particularly strong winds.

- Q:How do olive nets affect the production of olive tree sap?

- Olive nets play a vital role in the production of olive tree sap. By covering the olive trees, these nets prevent the olives from falling on the ground, ensuring that the sap remains intact. This helps in increasing the overall sap production as it minimizes the loss of olives due to wind, birds, or other factors. Additionally, the nets also provide shade to the olive trees, reducing water evaporation and creating a favorable environment for sap production.

- Q:Can olive nets be used for harvesting olives?

- Yes, olive nets can be used for harvesting olives. These nets are spread under the olive trees to catch the fallen olives during the harvesting process, making it easier to collect them and minimize damage.

- Q:Are olive nets safe for the environment?

- Yes, olive nets are generally considered safe for the environment. These nets are specifically designed to protect olive trees and prevent the olives from falling on the ground, ensuring a higher yield and reducing waste. They do not involve the use of harmful chemicals or pesticides, making them an eco-friendly option for olive farmers. Additionally, olive nets can also serve as a habitat for beneficial insects and birds, promoting biodiversity in the orchard ecosystem.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1.8mm Double Sided Polyester PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords