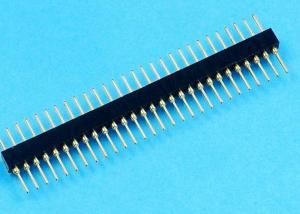

1.778mm Pin Connector Single Row

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 10000 Pieces per day pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1 Des: 1.778mm Pin Connector ,straight single or double row 11P

2 No of contacts : single row 01-40 Pins

3 Pin length : 12.33mm

4 Pin plated : G/F , AU:5U" act.( Upon the client request )

5 Insulator height : 3.0mm

6 Insulator material : PPS

7 All RoHS Complianced

- Q:Hi, I just bought a Nintendo Wifi USB connector and every time I inputted in the usb slot I hear the sound but nothing comes out On the bottom right screen as well I try searching my computer and nothing please help me out

- have okorder

- Q:I have a Sony Hi8 and Mini DV recorder deck and both have a DV connector on the front.Just recently I bought a mac pro and there is only Wire Fire ports.I have and will use Final Cut Pro X for cutting/editing.Is there any cable or adapter available to connect the Sony and mac for this?Thanks for any help and suggestions ?

- DV, okorder

- Q:If you have for example four #12 wires to connect together, it's a pain to twist them together. I've seen the push pin type of connectors with four slots. They seem very convenient. For you licensed electricians out there, are they code in a typical residential junction box?

- If I understand you correctly you are referring to the holes in the back of the receptacle. We call that back stabbing and it is only allowed on 15 amp general purpose receptacles. And the receptacle will not accept #12 wire, only #14. In addition (as the others have pointed out) it is a very poor quality connection. Don't do it. It is allowed by NEC but that's no excuse to go cheap or get lazy. Spring for a pair of lineman's pliers to make twisting the wires easy. You will need Red wire nuts for 4-5 #12wires. If you are referring to the push in style connectors, my experience has been that they too make a poor quality connection for receptacle use. I once connected 9 recessed lights using the factory supplied push in connectors. Thought I'd save a couple of minutes and a buck or two on yellow wire nuts. Of the 9, 6 failed to light up. I had to go back in, remove those connectors and replace them. My savings went right out the window! But it's your choice.

- Q:I have a large electric grill, the plates that cook food don't heat up properly, someone seems to have pulled on the cord causing one of the connectors that connects to the plate thermostat to come loose. It appears to have been forcefully melded with the thermostat, which I can't duplicate.

- check okorder

- Q:I just got a new PSU today (My previous one was dead when I bought it). It came with an 8-pin EPS 12V connector and a 4-pin ATX 12V connector. My motherboard supports both. I have a Intel i7 930 core. I've heard that I could plug in either one and it would still boot up, but I've also heard that plugging in the wrong one would either fry the CPU or cause instability. Which one should I plug in?PSU: Antec EarthWatt 500W

- If you have both, plug in the 8-pin EPS connector. It definitely won't hurt. It only makes a difference when you get into extreme overclocking (4+ GHz) and you start pulling ridiculous amounts of current through the CPU. The 130W Thermal Design Power of that processor isn't a maximum value, it's the normal, heatsink design level for running at stated clock speeds. Under extreme overclocking and overvolting, those silly processors can pull twice that much - assuming you have an extreme cooling system that keeps the cpu from burning up. At stock speeds, the 4 pin connector (rated for 150W @ 12V) is more than adequate.

- Q:I have a 1995 ford ranger and i cant seem to find the self-test connector can anybody help??

- Check under the instrument panel, on the driver's side, directly below the steering column for the 16-pin Data Link Connector. Even though it's a 1995 model year, some vehicles were already OBD-II compliant before 1996 model year. Hope this helps.

- Q:I want to connect my dvd player to this TV. The problem is that the TV only has the kind of screw in cable connection that comes from the wall. Now I have knowledge that the screw in cables are called coaxial cables.Does the black RCA port on the back of my dvd player marked coaxial have anything to do w/ the standard screw in RF coaxial? can i splice two ends together?

- Bumfighter is absolutely correct. It looks about right, but it's for sound only (and digital sound at that) so you'll get nowhere hooking it up. Try a converter as advised and you should be fine. Good luck

- Q:Alright building a computer for a client of mine and the tower has a front USB panel for easy convenience. The front panel has 3 separate cables. 2 of them are 4 pin USB internal cables and the other is a simple ground pin connector.

- check the webpage of the motherboard brand

- Q:I have PCV-RS430G with 2GB RAMand recently bought this --eXtreme Power 600W - RP-600-PCARWhen I get this vid card belowHIS Radeon X1600 Pro IceQ / 512MB GDDR2 / AGP 8x / DVI / VGA / HDTV / Video CardNot sure about how to connect the Power Connectors correctly.I know one goes into the graphics card and to the power supply. The last one goes into the hard drive but how??

- there is a special rate of voltage for your graphic card. some powersuppy come with the connect for that purpose. but u can buy a changer connector 12v for your card if the power supply have no graphic kad power connecter

- Q:For example, if you were to do the following: - Draw two box shapes on your slide - Connect them using a straight connector - Apply a motion path animation to one of the boxesThe resulting animation would show the box sliding across the screen as the connector lets go of the handle and remains stationary.Is it possible to force it to maintain the link?I can't find an elegant solution and neither Google nor Microsoft are helping eitherI'm using 2003Cheers,D'Arcy

- I'm unclear on your question - when I do this, the box moves and the connector stays exactly where it was. Do you actually want the connector to grow and stay attached to the box that moves (that makes the most sense)? Time to do a cheater animation. First, it might be easier to NOT use a connector - just draw a line. Then draw a second line from where that line ends to somewhere in the middle of where the box will move to. Send the loose line to the back. Note: you may have to zoom WAY in to be able to align the 2 lines perfectly. For the animation, do the motion path on the box and do a wipe on the loose line in the same direction the box is moving. Set it to go with previous. It ends up looking like the line is moving/growing along with the box moving over. If you are moving the box at an angle, it might look perfect, but if it is going straight to the side or up/down - it should work great. You might need to tweak timing a bit. EDIT: I was afraid of that ;D There is no good way to do what you want to do. Unfortunately, when using Grow/Shrink on a line, it not only grows the length, it grows the line weight, so doing a small spin with a grow on the line doesn't work. The best I could come up with (and it doesn't look as crappy as I would expect) is to have the starting line in position (up/down) and add a second line in the final (diagonal) position. Set the animation so that line 1 fades out with the start of the box moving (probably for the same animation length as the box - but you might want to make a little shorter) and line 2 fades in maybe 0.2 seconds later and ends at the same time as the box animation ends. I suspect you've tried this and didn't love it, but I'm 99% sure it's the best you'll do with PowerPoint.

Our Company specializes in the production of connectors for industrial and communication.Our company makes efforts to increase market competitiveness by aiming at the marked advanced level, following the market demand and providing the best after-sales service. Our development and production were completed via the communication and instruction.

1. Manufacturer Overview |

|

|---|---|

| Location | Shenzhen, China (Mainland) |

| Year Established | 2002 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2008; ISO 14001:2004; Production Assessment Certificate |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 4 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

1.778mm Pin Connector Single Row

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 10000 Pieces per day pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords