1.5mm EPDM membrane waterproofing For Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

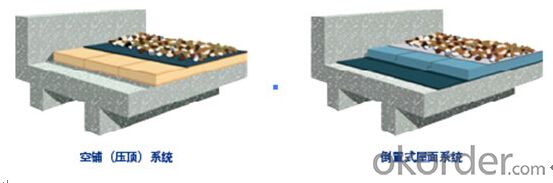

ROOF WATERPROOF SYSTEM-

EPDM MEMBRANE/COIL is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Application Scope

• Roofs, Basement, Toilet

•Industrial and civil building waterproofing

•Geo-synthetic liner for swimming pool, channels, irrigation system

•Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Advantagee

•Excellent weather-ability, durability and size stability

•Good adaptability to high and low temperature, UV resistant and anti-corrosion

•High tensile strength and good elongation, accommodating to structure movement

•Easy installation, solid joint, and no environmental pollution

•Good rooting penetration resistance

•Service life up to 50 years

Storage:

Shelf life is 12 months. Store in a cool and dry place with

original packing.

5,Demension:

1.2mmx1.2mx20m;1.5mmx1.2mx20m;2.0mmx1.2mx20m

Advantages

Technical Parameters

| Item | Index | ||||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

product show

factory show

FAQ

Q: What's the de6abf1fe186f8d58506cbcfe46eed814d.jpglivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q:Can a waterproofing membrane be used for shopping malls or commercial buildings?

- Yes, a waterproofing membrane can be used for shopping malls or commercial buildings. Waterproofing membranes are commonly used in construction to protect the structure from water damage. They are specifically designed to create a barrier against water infiltration, preventing leaks and moisture buildup. By applying a waterproofing membrane to the building's exterior, it helps to ensure the longevity and durability of the structure. Shopping malls and commercial buildings often have large surface areas that are exposed to different weather conditions, making them susceptible to water damage. Therefore, using a waterproofing membrane is an effective solution to protect these buildings and maintain their structural integrity.

- Q:Can a waterproofing membrane be used for residential swimming pools?

- Yes, a waterproofing membrane can be used for residential swimming pools. These membranes are specifically designed to provide a water-resistant barrier, preventing leakage and protecting the structure of the pool. Waterproofing membranes are commonly used in various applications, including swimming pools, to ensure durability and longevity of the pool.

- Q:Can a waterproofing membrane be used for podium decks and plaza areas?

- Yes, a waterproofing membrane can be used for podium decks and plaza areas. Waterproofing membranes are designed to provide a protective barrier against water and moisture, and are commonly used in a variety of applications including roofs, basements, and decks. Podium decks and plaza areas are also exposed to water and weather elements, making them suitable candidates for waterproofing membrane installation. The membrane acts as a waterproof layer, preventing water from penetrating the underlying structure and causing damage. It also helps to maintain the integrity and longevity of the deck or plaza by protecting it from moisture-related issues such as leaks, mold, and deterioration. Additionally, waterproofing membranes are available in various types and materials, allowing for flexibility in choosing the most appropriate membrane for the specific project requirements.

- Q:Roof SBS waterproofing membrane can not empty shop

- 3, under normal circumstances, with ordinary SBS coil roof waterproof, to Shitao as well, to prevent the emergence of a little water into the overall failure of the string of water phenomenon.

- Q:Can a waterproofing membrane be exposed to sunlight?

- Yes, a waterproofing membrane can be exposed to sunlight. In fact, many waterproofing membranes are designed to withstand prolonged exposure to sunlight without deteriorating or losing their effectiveness. However, it is important to note that not all waterproofing membranes are equally resistant to UV rays, so it is crucial to choose a membrane that is specifically designed for outdoor use and can handle exposure to sunlight. Additionally, it is always recommended to follow the manufacturer's instructions and guidelines for the specific waterproofing membrane being used to ensure its longevity and performance.

- Q:Is a waterproofing membrane resistant to punctures or tears?

- A waterproofing membrane is created to resist punctures or tears, being made from robust materials like PVC, TPO, or EPDM, renowned for their strength and damage resistance. These membranes undergo extensive testing to ensure they can endure different environmental conditions and potential causes of punctures or tears, like sharp objects or heavy foot traffic. Some waterproofing membranes even have reinforcement layers or added protection to further strengthen their resistance to punctures and tears. Nevertheless, it is crucial to note that while waterproofing membranes are highly durable, they are not entirely immune to damage. Proper installation, regular maintenance, and avoiding unnecessary stress or impact on the membrane can help extend its lifespan and enhance its performance.

- Q:Can a waterproofing membrane be used for a basement wall?

- Certainly, a basement wall can indeed benefit from the use of a waterproofing membrane. It is highly advisable to employ such a membrane on basement walls in order to thwart water infiltration and potential harm. Given their subterranean position, basement walls are especially susceptible to moisture; thus, a waterproofing membrane serves as a reliable barrier against water penetration. Typically, this membrane is applied to the exterior surface of the basement wall, forming a protective layer that maintains the basement's dryness and hinders water from seeping into the foundation. It is imperative to ensure the proper installation and upkeep of the waterproofing membrane to effectively protect the basement against water-related problems such as leaks, mold, and structural damage.

- Q:Can a waterproofing membrane be used for planter boxes?

- Yes, a waterproofing membrane can be used for planter boxes. A waterproofing membrane is designed to prevent water from seeping through surfaces and can be an effective solution for preventing water damage to the planter box and its surroundings. By installing a waterproofing membrane on the inside of the planter box, it creates a barrier that keeps water from reaching the underlying materials, such as wood or concrete, and helps to extend the lifespan of the planter box. Additionally, a waterproofing membrane can also help to retain moisture within the planter box, which can be beneficial for the plants growing inside. However, it is important to select a waterproofing membrane that is specifically designed for planter boxes and is safe for use with plants to ensure the best results.

- Q:Can a waterproofing membrane be used in basements and foundations?

- Basements and foundations can benefit greatly from the use of a waterproofing membrane. It is highly recommended to apply this protective layer in order to safeguard against water infiltration and moisture-related problems. Typically, the membrane is applied on the outer side of the foundation walls and basement floors, effectively creating a barrier that prevents water from permeating through the concrete. This essential measure ensures that the basement and foundation remain dry, minimizing the risk of water damage, mold growth, and structural complications. There are several types of waterproofing membranes available, including bituminous, rubberized asphalt, and liquid-applied options. This variety allows for flexibility when selecting the most suitable option according to the specific project requirements. Ultimately, installing a waterproofing membrane is a reliable means of improving the overall resilience and longevity of basements and foundations.

- Q:Can a waterproofing membrane be used for bathrooms or showers?

- Yes, a waterproofing membrane can be used for bathrooms or showers. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water leakage and damage to the underlying structure. The membrane is typically applied to the walls and floor of the bathroom or shower area to create a barrier that prevents water from seeping through. This helps to protect the surrounding areas from moisture, mold, and mildew growth. Additionally, a waterproofing membrane can also help to prolong the lifespan of the bathroom or shower by preventing water damage and deterioration. Overall, using a waterproofing membrane is an effective solution to ensure the durability and longevity of bathroom and shower areas.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1.5mm EPDM membrane waterproofing For Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords