1.4301 SUS 304 Stainless Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Standard:

AISI,ASTM,JIS,GB,BS,DIN,API,EN

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

A53(A,B),20#,10#,SS400-SS490,600 Series,400 Series,300 Series,Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series

Certification:

SGS,ISO,RoHS,IBR,BV,UL,BSI,API,CE

Thickness:

2.5-500

Length:

6000

Net Weight:

1-5T

Stainless steel bars,profiles,beams

Product Information:

| 200 series: 201, 202 | |

| 300 series: 303, 304, 304L,321, 310S, 316, 316L | |

| 400 series: 410, 420, 430 | |

| Standard | AISI, ASTM, DIN, GB, JIS, SUS |

| Diameter | 2mm-300mm |

| Length | 1 meters to 9 meters or random |

| Surface | bright, black |

| Treatment | Hot rolled, cold drawn, Annealed, Grinding |

| Packing | Standard sea-worthy package or as required |

| Trade Terms | EXW, FOB, CFR, CIF |

| MOQ | 200 KGs Stainless Steel Round Bar |

| Payment | 30% deposit in advance, balance against copy of BL or irrevocable L/C at sight |

| Delivery | Usually 15-20 days upon receipt of deposit for 1 FCL |

Product Size Detail:

| Main operation | Main steel grade | Available size(mm) | Monthly capacity(mt) | Length(mm) | ||

| OEM | Stainless steel | 40~500 | 1500 | 4000~8000 | ||

| Hot | 303 303Cu 304/L 310S 316/L 321 416 420 | 12 ~200 | 3000 | 4000~7000 | ||

| 17-4PH WLA510 | ||||||

| ST Bar | 321 304/L 316/L 310S 17-4PH WLA510 | 19~110 | 2000 | 4000~7000 | ||

CD Bar | Round bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | |

| Square bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| Hex bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| CG Bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | ||

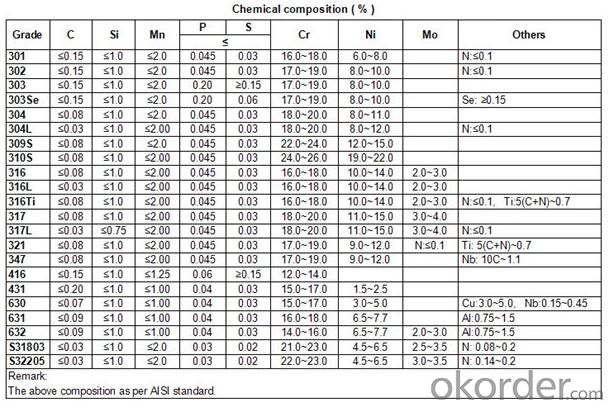

Specificate:

Our Advantages

• All products are made of high-quality imported raw materials.

• Our products are certified by ISO9001:2008 authentication quality systems.

• we are nominated as the AAA enterprise by Jiangsu government.

• Quick Response to Your Enquiry.

- Q:Can stainless steel bars be used in the manufacturing of distillation columns?

- Yes, stainless steel bars can be used in the manufacturing of distillation columns. Stainless steel is a popular choice of material for distillation columns due to its excellent corrosion resistance and high strength. Distillation columns are used in various industries, including chemical, pharmaceutical, and petroleum, to separate and purify different components of a mixture. The use of stainless steel bars ensures that the distillation column can withstand the harsh conditions and corrosive environments typically encountered in these industries. Additionally, stainless steel bars can be easily formed and welded, allowing for the customization and fabrication of distillation columns to meet specific requirements.

- Q:What is the difference between cold drawn and peeled stainless steel bars?

- Both cold drawn and peeled stainless steel bars are popular for various applications, but they differ significantly in terms of how they are manufactured and the properties they possess. To produce cold drawn stainless steel bars, the raw material is pulled through a series of dies at room temperature. This process enhances the steel's mechanical properties, including its tensile strength and hardness. It also improves the surface finish and dimensional accuracy, resulting in a smooth and shiny appearance. Cold drawn bars are ideal for applications where aesthetics play a crucial role. Furthermore, they exhibit closer dimensional tolerances and a more uniform microstructure compared to other manufacturing methods. On the contrary, peeled stainless steel bars are manufactured by removing the outer layer of the bar through a peeling process typically conducted at high temperatures. This process eliminates any imperfections or surface defects, resulting in a smooth and clean surface finish. Peeling also enhances the straightness and roundness of the bar, making it suitable for applications where precise dimensions and alignment are crucial. However, the peeling process does not significantly impact the steel's mechanical properties, meaning that peeled bars may possess similar properties to the original material. In summary, the primary distinction between cold drawn and peeled stainless steel bars lies in their manufacturing processes and resulting properties. Cold drawn bars undergo a cold drawing process to enhance mechanical properties and surface finish, while peeled bars undergo a peeling process to improve surface quality and dimensional accuracy. Thus, the selection between the two options depends on the specific requirements of the application, such as the desired mechanical properties, surface finish, and dimensional tolerances.

- Q:What's the difference between 304 stainless steel round bar and 304F stainless steel round bar?

- The 304F standard hardness of HRB 90-100, which belongs to BITAUTO stainless steel, 304F stainless steel bar by a small amount of sulfur and phosphorus added to more than 304 cutting 304F stainless steel rod, belonging to the 304 series of national standard (0Cr18Ni9)

- Q:Can stainless steel bars be used in wastewater treatment applications?

- Certainly, wastewater treatment applications can indeed utilize stainless steel bars. The reason behind the extensive usage of stainless steel in wastewater treatment plants lies in its exceptional resistance to corrosion and its remarkable durability. It possesses the ability to endure exposure to a wide range of chemicals, contaminants, and high moisture environments that are commonly encountered in wastewater treatment facilities. Stainless steel bars are employed for various purposes within wastewater treatment, such as the construction of tanks, pipes, screens, and other structural elements. They exhibit an exceptional resistance to rust and corrosion, resulting in an extended lifespan for the equipment and diminished maintenance costs. Furthermore, stainless steel is known for its hygienic properties and ease of cleaning, making it a suitable choice for applications where cleanliness and sanitation hold great importance.

- Q:How do stainless steel bars resist staining and discoloration?

- Stainless steel bars resist staining and discoloration due to their high chromium content, which forms a protective layer on the surface when exposed to oxygen. This layer, known as chromium oxide, acts as a barrier, preventing corrosion, staining, and discoloration from occurring.

- Q:Are stainless steel bars suitable for elevator components?

- Stainless steel bars are indeed a suitable option for elevator components. Elevator components, including guide rails, door frames, brackets, and handrails, can be crafted from stainless steel bars to ensure durability and long-lasting performance. One of the reasons why stainless steel is a popular choice for elevator components is its exceptional corrosion resistance, strength, and durability. It is able to withstand the constant exposure to moisture, humidity, and various environmental conditions, making it ideal for elevator applications. Moreover, stainless steel's resistance to rust and staining adds to its suitability for elevator systems. The smooth surface finish of stainless steel is also vital for ensuring smooth and safe elevator operation. All in all, stainless steel bars are widely used in the manufacturing of elevator components due to their superior properties and ability to meet the rigorous demands of elevator systems.

- Q:Can stainless steel bars be used in the manufacturing of appliances?

- Yes, stainless steel bars can be used in the manufacturing of appliances. Stainless steel is a durable and corrosion-resistant material that is commonly used in the production of appliances due to its strength, heat resistance, and aesthetic appeal.

- Q:What is the difference between stainless steel bars and carbon steel bars?

- The main difference between stainless steel bars and carbon steel bars lies in their composition. Stainless steel bars contain a higher percentage of chromium, which provides them with excellent corrosion resistance. They also typically contain nickel and other alloying elements, making them more durable and resistant to heat and chemicals. On the other hand, carbon steel bars have a higher carbon content, which gives them greater strength and hardness but makes them more susceptible to corrosion. Overall, stainless steel bars are ideal for applications requiring resistance to corrosion, while carbon steel bars are favored for their strength and toughness.

- Q:Can stainless steel bars be used in the HVAC industry?

- Yes, stainless steel bars can be used in the HVAC industry. Stainless steel is a popular material choice for HVAC applications due to its exceptional corrosion resistance, high strength, and durability. It is commonly used for manufacturing various components such as ductwork, heat exchangers, pipes, and supports in HVAC systems. Stainless steel bars offer excellent resistance to rust, oxidation, and chemical corrosion, making them suitable for use in environments with high moisture, humidity, or exposure to corrosive substances. Additionally, stainless steel bars can withstand extreme temperatures and have good thermal conductivity, making them ideal for transferring heat efficiently in HVAC systems. Overall, stainless steel bars are a reliable and long-lasting material option for the HVAC industry.

- Q:The difference between 440C stainless steel bars and 420 stainless steel bars

- 440C stainless steel bars and 420 stainless steel bars are also of high hardness, and different places are 440C wear-resistant

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1.4301 SUS 304 Stainless Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords