1.3-19mm FLOAT Glass,TEMPERED Glass, MIRROR Glass,LAMINATED Glass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass:

We manufacture a wide range of glass to meet your different demands: Float glass, Tinted glass, Stained glass, Laminated glass, Mirror glass, Aluminum mirror, Silver mirror, Reflective glass, Online coated glass, Patterned glass, Figured glass, Wired glass, Colored glass, Tempered glass, Toughened glass, Safety glass, Shower doors glass, Emulsificated glass, Acid-etched glass, Obscure glass, Sandblasted glass, Solar glass, Ultra clear low iron glass, Low-E glass, Obscure glass, Glass block, Glass brick, Picture frame in different colors and sizes.

2.Main features of Glass:

1) Standard: CCC, intertek

2) 3 - 19mm float glass

3).Size: customized sizes available

4).tempered or silk

5).drill work available

6).Printing Furniture Glass ,Beautiful surface with good coverage.

Profiled glass, as your design and requirement

Type: clear, tinted, color glazed, coated, Low-E, IGU and laminated glass etc.

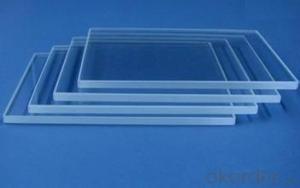

3.Glass Images:

4. Glass Technical Parameters:

CLEAR FLOAT GLASS

Thickness: 2mm-19mm

Sizes: 1524x2134mm, 1830x2440mm, 2140x3300mm, 2140x3660mm, 2250x3300mm, 3660x2140mm, 3660x2250mm etc.

EXTRA CLEAR GLASS

Thickness: 3mm-19mm

Sizes: 1830x2440mm, 2140x3300mm, 2140x3660, 2250x3300mm, 2250x3660mm etc.

TINTED GLASS

Colors: Euro Bronze, Golden Bronze, Euro Grey, Mist Grey, Dark Grey, French Green, Dark Green, Lake Blue, Dark Blue, Ocean Blue, Pink etc.

Thickness: 3mm-12mm

Sizes: 1524x2134mm, 2140x3300mm, 2250x3210, 2250x3300mm, 2140x3660mm, 2250x3160mm etc.

REFLECTIVE GLASS

Colors: Euro Bronze, Golden Bronze, Euro Grey, Dark Grey, French Green, Dark Green, Lake Blue, Dark Blue, Pink, Silver etc.

Thickness: 3mm-10mm

Sizes: 1524x2134mm, 2140x3300mm, 2250x3210, 2250x3300mm etc.

MIRROR

Types: Silver Mirror, Aluminum Mirror, Copper and Lead Free Mirror, Safety Mirror, Solar Mirror and Beveled Mirror etc.

Thickness: 1.5mm, 1.8mm, 2mm, 2.7mm, 3mm, 4mm, 5mm and 6mm etc.

Sizes: 1524x2134mm, 1830x1220mm, 1830x2440mm, 2140x3300mm, 2250x3300 etc.

LAMINATED GLASS

PVB Color: Clear, Green, Blue, Bronze, Grey, Milk white etc.

Glass Color: Clear, French Green, Dark Green, Ford Blue, Dark Blue, Bronze, Euro Grey etc. Float glass and reflective glass are available.

Thickness: 3+0.38+3mm, 4+0.38+4mm, 5+0.38+5mm, 6+0.38+6mm, 3+0.76+3mm, 4+0.76+4mm, 5+0.76+5mm, 6+0.76+6mm etc. till to 42.3mm

Sizes: 1830x2440mm, 2140x3300mm etc.

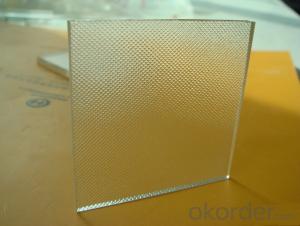

PATTERNED GLASS

Thickness: 3mm, 3.5mm, 4mm, 5mm, 6mm and 8mm

Sizes: 1220x1830mm, 1524x2134mm, 1830x2440mm, 3300x2140mm etc.

Patterns: Aqualite, Bamboo, Beehive, Chinchilla, Crystal, Diamond, Flora, Karatachi, Masterlite, Millennium, Mistlite, Morgon II, Moru, Nashiji, Rain and Wanji etc.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:How is glass made?

- The main raw materials of flat glass are: silica sand (sandstone), sodium carbonate, feldspar, dolomite, limestone and mirabilite.

- Q:The main chemical constituents of ordinary glass

- The raw materials for making ordinary glass are soda ash, limestone and quartzThe composition of common glass chemical oxides (Na2O, CaO, 6SiO2), the main component is silica

- Q:How to seal the glass fiber reinforced plastic mould?

- Step up. Concave convex surface or Z face.

- Q:What are the aluminum films used in glass processing enterprises?

- (1) the enterprise purchase and acceptance of storage materials, the planned cost or actual cost, debit "raw material" subjects, according to the actual cost of credit "material procurement" or "goods in transit" subjects, according to the difference between the planned cost and actual cost, debit or credit "material cost difference" course.

- Q:What is the raw material of glass products?

- Ordinary glass raw materials are soda ash (sodium carbonate), limestone (calcium carbonate) and silica, after a high temperature reaction, the products are mainly sodium silicate, calcium silicate and silica

- Q:What are the raw materials for producing edible glass bottles (such as pickles bottles, fermented beancurd bottles, etc.), and glass is the kind of glass material?

- In the production of glass products, raw materials are divided into general white material, high white material, super white material, and white material, the quality is getting better, he directly affects the glass transparency and crispness, better raw materials produced better quality glass products.

- Q:Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Ceramic crystallization: glass ceramic composite board is the product of "three in one" of glass, ceramic and stone craft. It combines the glass melting process, ceramic brick molding and crystallization sintering process, stone polishing, cutting process as a whole. In short, microcrystalline glass frit is special stalls shop in the special ceramic tile on the roller kiln sintering crystallization, after polishing and cutting timber.

- Q:What kind of raw material does glass form? What is the general smelting process?

- Before people made of glass which has a lot of people use a lot of bubbles, there is no way to take out that European countries made out of glass without bubbles, other countries about the scary, stirring

- Q:The main raw material for the impact of float glass cost?

- Process: mainly to see whether the enterprise has mastered the key technology of float process control. For example, master the melting technology, need to have stripe analysis equipment to monitor, can detect fault signs in advance, timely fine-tuning, can avoid major accidents, development. In the case of melting stability, general forming and annealing are relatively easy to achieve stability; the products produced by such a line are stable and the cost will be greatly reduced. But at present, the only part of enterprises to master the technology, many enterprises are repeatedly in fluctuation, a fluctuation of about 3-7 days, so the product quality can not guarantee long-term stability, there is no guarantee to do the processing of glass, benefits decline.

- Q:What is the raw material of glass?

- How is glass produced? Glass production process includes batching, melting, forming, annealing and other processes. The following are described below:1. ingredients, according to the design of the material sheet, weighing all kinds of raw materials, mixing in a mixing machine evenly. The main raw materials of glass are: quartz sand, limestone, feldspar, soda ash, boric acid and so on.2., melting, the raw materials will be prepared by high temperature heating, forming a homogeneous bubble free liquid glass. This is a complex process of physics and chemistry. The melting of glass is carried out in a furnace. There are two main types of Furnaces: one is a crucible kiln, the other is glass in the crucible, and the other is heated outside the crucible. The small crucible kiln has only one crucible, and the larger one can be more than 20 crucibles. The crucible kiln is made by gap type, and now only optical glass and color glass are produced by crucible kiln. The other is the tank furnace. The frit is molten in the bath, and the flame is heated on the upper part of the glass. The glass melting temperature mostly in the 1300~1600 C Eve joy. Most of them are heated by flame and a few are heated by electric current. They are called electric furnaces. Now, the pool kiln is continuous production, small pool kiln can be a few meters, big can be more than 400 meters, 2.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1.3-19mm FLOAT Glass,TEMPERED Glass, MIRROR Glass,LAMINATED Glass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords