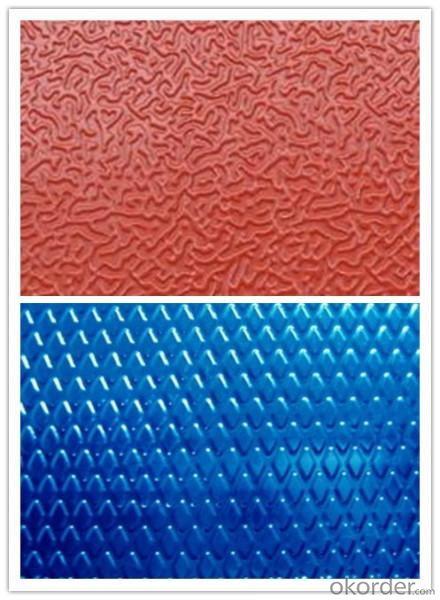

1-10mm Cost Price Embossed Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Grade:

1000 Series,3000 Series,4000 Series,5000 Series,6000 Series,7000 Series,2000 Series

Surface Treatment:

Coated,Embossed,Anodized,Polished,Mill Finish,Color Coated,Oxidized,Enameled Wire,Brushed,Printed,Composited,Holographic Impression,Sand Blasted,Powder Coating

Shape:

Angle,Square,T-Profile,Round,Flat,Rectangular,Oval,Hexagonal

Temper:

T3-T8,O-H112,T351-T651,T351-T851,Soft,Half Hard,Hard

Application:

Liner & Wad,Decorations,Door & Window,Heat Sink,Transportation Tools,Glass Wall,Food,Kitchen Use,Pharmaceutical,Seal & Closure,Insulation Material,Label & Tag

Parameters:

| Division | Description | Application | Feature |

| 1000 SERIES | 1050 1060 1090 1100 representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. | Utensil, decoration, Reflecting plate, printing plate, heatproof plate,cookware | Easy to process and weld,resistant to rust,high,conductibility of electricity and heat,low strength |

| 3000 SERIES | 3xxx series aluminum represents 3003 3004,3005. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment | Utensil(F/P, inside of rice cooker), aluminum can,material for interior and exterior of building,chemical equipment,Cellular Phone | 20% higher strength than the 1100 series, easily welded and brazed, good antirust,ability Non-heat treatable |

| 5000 SERIES | 5xxx series representatives 5052 5005 5083,5754. The 5000 series aluminum alloy aluminum belong to the more commonly used series, the main elements for magnesium, with magnesium in the amount between 3-5%. And can be called aluminum magnesium alloy. Key features for low density, high tensile strength, elongation rate is high. In the same area under the weight of the magnesium alloy aluminum less than other series. | Ship board heatproof apparatus, material for interior and exterior of building, Parts of Electronic tools.Automobile Components | Excellent corrosion resistance andweld ability together with Easy to process and weld and superior hardness &heatproof Can be anodized for increased corrosion resistance |

| 6000 SERIES | 6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications. | IT equipment & facility, Mould material, motor material, automatic line, machine & plant etc | Easy to process , good corrosion resistance, high toughness and processed without distortion after heat-treatable, superior surface treatment |

| 7000 SERIES | 7000 aluminum alloy is another common alloy, wide variety. It contains zinc and magnesium. The best strength in the common aluminum alloy is 7075 alloy, but it can't be welded, and its corrosion resistance is rather poor, many manufacturing parts with CNC cutting is 7075 alloy. | The aerospace industry & High strength accessories | 7000 series is high tensile to process with special alloy |

Product picture

- Q:Can the aluminum sheets be used for manufacturing chemical piping systems?

- Yes, aluminum sheets can be used for manufacturing chemical piping systems.

- Q:Can aluminum sheet be painted?

- Yes, aluminum sheet can be painted. However, it is important to properly prepare the surface before painting to ensure that the paint adheres well and lasts longer. The process usually involves cleaning the aluminum sheet to remove any dirt, grease, or oxidation, followed by applying a primer to promote better adhesion. Once the primer is dry, you can then apply the paint of your choice. It is recommended to use a high-quality paint suitable for metal surfaces to achieve the best results. Additionally, if the aluminum sheet will be exposed to outdoor elements, it is advisable to use a paint that is specifically formulated for exterior use, in order to provide protection against weathering and corrosion.

- Q:Can anyone tell me what to be careful of if you have aluminum wiring in your house. I was told that if the wall gets hot, I need to tighten the screws of the inside switch. Is this true and if I didn't, would it actually cause a fire in the wall. If this is true, how often does it loosen?

- Several answers are very good but the one thing that evrybody failed to mention is each device (switch, recept, fixture, etc.) must be listed to use with AL wire. This is the biggest problem I find. Home owners run out to the local hardware and pick up a new device and do not check the listings. The copper wire pig tail is an option but once again you must use a wire nut that is listed for both AL CU wiring. Most are a dark purple in color. Electrical Inspector

- Q:what will happen when aluminum sheet is put into copper chloride solution?

- the chemical equation of the reaction, 2Al+3CuCl2=2AlCl3+3Cu, the phenomena when aluminum sheet is put into copper chloride solution: there is red solid generating on the surface of aluminum sheet.

- Q:Can aluminum sheets be polished for a mirror-like finish?

- Indeed, a mirror-like finish can be achieved by polishing aluminum sheets. Due to its relatively soft nature, aluminum can be effortlessly polished to a remarkable shine. Typically, the process entails sanding the surface using increasingly finer grades of sandpaper, then buffing with polishing compounds and a gentle cloth or a polishing wheel. The objective is to eliminate any blemishes or marks on the surface, resulting in a sleek and reflective appearance. By employing proper methods and tools, aluminum sheets can be polished to an exquisite shine, rendering them ideal for diverse applications such as decoration, automotive components, or reflective surfaces in optical instruments.

- Q:Can someone please help me with the resonance structure for AlCl3. When I draw it, the central Al does not have a complete octet. I read that this is usually the case for atoms like Boron and Aluminium who only have three valence electrons. Is this correct? Also, as a follow on question, does AlCl3 display resonance?

- I'll do NO2- as an example. The Lewis structure is O=N-O with two electron pairs on the left O and 3 electron pairs on the right O and one electron pair on the N. But you could also draw it as O-N=O. So, those are the two resonance structures. The actual is where N has 1.5 bonds to each O on average.

- Q:Are aluminum sheets suitable for harsh weather conditions?

- Aluminum sheets are highly suitable for harsh weather conditions due to their exceptional properties. Aluminum is a lightweight yet durable material that offers excellent resistance against corrosion, rust, and UV radiation. This makes it particularly resilient against the damaging effects of extreme weather conditions such as heavy rain, snow, high winds, and intense sunlight. Furthermore, aluminum has a high strength-to-weight ratio, allowing it to withstand the pressure exerted by severe weather without sustaining significant damage. Additionally, aluminum sheets can be coated with protective finishes such as anodization or powder coating, further enhancing their ability to withstand harsh climates. Overall, aluminum sheets are an excellent choice for applications requiring resilience in harsh weather conditions.

- Q:we have the mass of an aluminum sample =.47g, and the number of atoms in sample =107

- Look up the atomic mass of aluminum on your periodic table, multiply by 107, then divide by .47g?

- Q:What is the typical cost-effectiveness of aluminum sheets compared to other materials?

- Aluminum sheets are generally considered to be cost-effective compared to other materials. This is primarily due to their abundance, lightweight nature, and recyclability, which reduces production costs. Additionally, aluminum sheets offer a high strength-to-weight ratio, corrosion resistance, and durability, making them a popular choice across various industries. However, specific cost-effectiveness may vary depending on factors such as market demand, sheet thickness, and finishing requirements.

- Q:I am using Reeves Acrylic Colour Set and I plan on painting on Heavy Duty Ralphs Brand Aluminum Foil. Will the paint be able to go on the foil well? Tips? Thank you.

- i use aluminum foil to mix colors on and when it dries it DOES stick, however, it will scratch off really easy. just try experimenting. what do u need the foil for? maybe you can try the aluminum foil leaves? the flakes that you put ontop on the art instead of under it. that way you can glue it on and dont have to worry about it scratching off. foil looks beautiful on paintings :) how it turns out great

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1-10mm Cost Price Embossed Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords