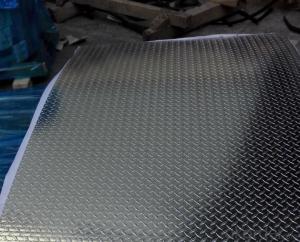

0.7 mm Thick Embossed Aluminum Zinc Roofing Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description of 0.7 mm Thick Embossed Aluminum Zinc Roofing Sheet

Alloy | Temper | Specification(mm) | ||||

Thickness | Width | Length | Embossing Depth | Surface Treatment | ||

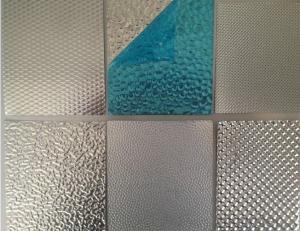

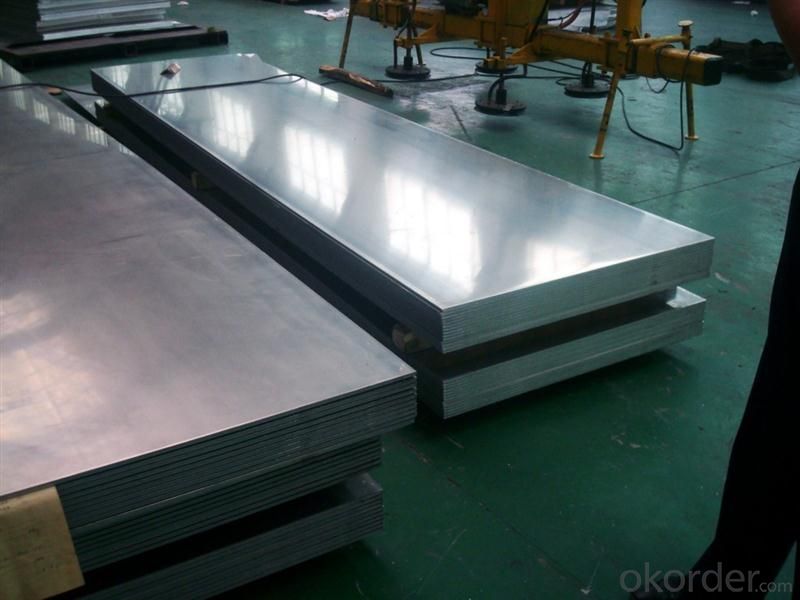

1050, 1060, 1100, 1070, 3003, 3105, etc. | O, H12, H14, H16, H18, H22, H24, H26, H32, etc. | 0.25~2.0 | ≤1250 | As per customer’s | 0.08~0.25 | Mill Finish, Bright Finish, Anodized, Color Coated |

Tolerance | ||||||

Thickness (base materials) | Thickness | Embossing Depth | Width | Length | Diagonal | |

0.25~0.5 | 0~0.05 | +/- 0.01 | +/-0.5 | +/- 1.0 | +/- 1.5 | |

> 0.5~2.0 | 0~0.10 | +/- 0.02 | +/-1.0 | +/- 1.5 | +/- 2 | |

We can produce as per customers’ special requirements. | ||||||

Chemical composition 0.7 mm Thick Embossed Aluminum Zinc Roofing Sheet

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Other | Min Al/ % | ||

Single | Total | ||||||||||||

3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | - | - | 0.10 | - | - | 0.05 | 0.15 | Remain |

3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | 0.15 | - | 0.25 | - | - | 0.05 | 0.15 | Remain |

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q:Can aluminum sheets be used for packaging applications?

- Yes, aluminum sheets can be used for packaging applications. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various packaging purposes such as food and beverage containers, pharmaceutical packaging, and cosmetic packaging. It provides a barrier against moisture, oxygen, and light, ensuring the protection and preservation of the packaged products. Additionally, aluminum is recyclable, contributing to sustainability efforts in the packaging industry.

- Q:What kind of material is 2A12 aluminum sheet?

- 2A12 is a typical Al Mg alloy in Al Cu mg system. Its composition is reasonable and its comprehensive properties are better. Many countries produce this alloy, which is the largest in use. The alloy is characterized by high strength, a certain heat resistance, and can be used as working parts below 150 degrees C.

- Q:Can aluminum sheets be an alternative to stainless steel?

- In certain applications, aluminum sheets can serve as a viable substitute for stainless steel. Aluminum, a lightweight metal, exhibits a favorable strength-to-weight ratio, making it suitable for various industries including aerospace, automotive, and construction. Similar to stainless steel, aluminum boasts a high level of corrosion resistance due to the formation of a protective oxide layer on its surface. When it comes to cost-effectiveness, aluminum sheets can prove advantageous over stainless steel, particularly in large-scale projects where reduced weight can lead to lower transportation and installation expenses. Furthermore, aluminum possesses excellent thermal and electrical conductivity, making it an appropriate choice for applications requiring such properties. Despite these advantages, stainless steel still outshines aluminum in certain aspects. Generally, stainless steel is stronger and more durable, rendering it suitable for heavy-duty applications or environments that demand high mechanical strength. Moreover, stainless steel exhibits superior resistance to extreme temperatures and fire, which can be critical in specific applications. In conclusion, while aluminum sheets can serve as an alternative to stainless steel in many scenarios, the ultimate selection hinges upon the specific requirements of the application, encompassing factors such as strength, durability, corrosion resistance, and cost.

- Q:What are the aluminum plates for?

- The products are widely used in construction, curtain wall, packaging, food, air conditioners, refrigerators, solar energy, automobile manufacturing, ship manufacturing, machinery manufacturing, cosmetics packaging and other electrical appliances, machinery manufacturing industry, can also be used in power plants, chemical and petrochemical industry factory anticorrosion & insulation etc..Shandong Pingyin Hengshun Aluminium Co., Ltd. specializing in the production of (hot rolling, cold rolling aluminum alloy) roll. Aluminum coil. Alloy aluminum. Aluminum. Ultra wide / ultra thick aluminium alloy. Sawing, shearing customer requirements specification aluminum alloy thick aluminum wire, aluminum, aluminum flange with aluminum, power plant / chemical anticorrosion and insulation alloy factory aluminum moisture-proof aluminum roll roll.

- Q:Are aluminum sheets conductive?

- Indeed, aluminum sheets possess conductivity. Being a metal, aluminum exhibits exceptional electrical conductivity. Consequently, aluminum sheets facilitate the smooth passage of electricity, rendering them suitable for an array of applications that necessitate conductivity, including electrical wiring, power transmission lines, and electronic devices.

- Q:Can 101 aluminum sheets be used in electrical or electronic components?

- Yes, 101 aluminum sheets can be used in electrical or electronic components. Aluminum is a versatile metal that possesses excellent electrical conductivity and is widely used in various electrical and electronic applications. It is commonly used as a conductor in power transmission lines, electrical cables, and wiring. Additionally, aluminum sheets can be used in the manufacturing of electronic components such as heat sinks, circuit boards, and enclosures due to their lightweight, corrosion-resistant, and thermally conductive properties. However, it is important to note that the specific grade and alloy of aluminum, as well as other factors such as thickness and surface treatment, may also influence its suitability for certain electrical or electronic applications.

- Q:What are the common surface finishes for aluminum sheets?

- Aluminum sheets can be finished in various ways, including mill finish, brushed finish, anodized finish, and powder-coated finish. The mill finish refers to the untreated surface of the aluminum sheet, which has a slightly rough texture and may show imperfections. It is a basic and cost-effective option, often used in industrial applications or as a base for further finishing processes. For a textured appearance and to conceal minor scratches or imperfections, the brushed finish involves a mechanical brushing process that creates fine parallel lines on the aluminum sheet's surface. The anodized finish is achieved through an electrochemical process called anodization, which forms a protective oxide layer on the aluminum's surface. This finish enhances its corrosion resistance and durability, and it also offers a range of color options. Anodized aluminum sheets are commonly used in architecture or for decorative purposes. In the powder-coated finish, a dry powder is applied to the aluminum sheet's surface and then baked at high temperatures. This creates a durable and attractive finish that is resistant to chipping, scratching, and fading. Powder-coated aluminum sheets are often used outdoors in applications such as building facades, signage, or automotive parts. Ultimately, the choice of surface finish for aluminum sheets depends on the desired appearance, functionality, and specific requirements of the application.

- Q:Are aluminum sheets suitable for automotive body reinforcements?

- Yes, aluminum sheets are suitable for automotive body reinforcements. Aluminum is a lightweight material that offers high strength-to-weight ratio, making it an ideal choice for automotive applications. It provides excellent corrosion resistance, which is crucial for vehicles exposed to various weather conditions and road salts. Additionally, aluminum sheets can be easily formed and welded, allowing for seamless integration into the body structure. The use of aluminum sheets in automotive body reinforcements helps reduce the overall weight of the vehicle, leading to improved fuel efficiency and performance. Furthermore, aluminum is a recyclable material, aligning with the automotive industry's increasing focus on sustainability. Hence, aluminum sheets are indeed a suitable choice for automotive body reinforcements.

- Q:What are the different surface finishes available for aluminum sheets?

- Some of the different surface finishes available for aluminum sheets are mill finish, brushed finish, anodized finish, and embossed finish. Mill finish is the natural appearance of the aluminum without any additional treatment. Brushed finish involves brushing the surface to create a textured appearance. Anodized finish involves an electrolytic process that forms a protective layer on the surface and can be colored. Embossed finish involves creating patterns or designs on the surface using pressure or heat.

- Q:If something is wrong, what kind of glue can be used for bonding the stainless steel sheet and aluminum sheet? The area may be very big. What are some common or good glue to buy?

- There are two methods: 1 AB glue or epoxy resin adhesive. 2. If the thickness of the two plate is greater than 8MM, it can be fixed by flat screw. Hope to be available.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

0.7 mm Thick Embossed Aluminum Zinc Roofing Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords