0.4mm Thick PPGI Metal Sheet for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

0.4mm Thick PPGI Metal Sheet

Description of 0.4mm Thick PPGI Metal Sheet

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of 0.4mm Thick PPGI Metal Sheet

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

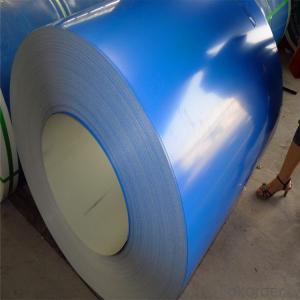

Products Show of 0.4mm Thick PPGI Metal Sheet

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q:What are the different inspection methods used for special steel?

- There are several inspection methods used for special steel, including visual inspection, magnetic particle inspection, ultrasonic testing, radiographic testing, and dye penetrant inspection. These methods help identify any surface defects, cracks, or internal flaws in the steel, ensuring its quality and integrity.

- Q:What are the properties of martensitic steel?

- Martensitic steel is a specific type of stainless steel that possesses several distinct properties. It is known for its high strength, hardness, and wear resistance, making it suitable for applications where toughness and durability are crucial. Additionally, martensitic steel can be easily heat treated to enhance its mechanical properties, such as increasing its strength or improving its corrosion resistance. However, it has lower corrosion resistance compared to other stainless steel types and can be prone to cracking under certain conditions.

- Q:What are the requirements for special steel used in cryogenic applications?

- To ensure optimal performance and reliability in extremely low-temperature environments, special steel employed in cryogenic applications must fulfill a range of prerequisites. First and foremost, the steel must exhibit exceptional low-temperature toughness, enabling it to endure the extreme cold without succumbing to brittle fracture or compromising its mechanical properties. It is imperative that the steel possesses high toughness and ductility to effectively absorb impacts and prevent cracking. Moreover, the steel must possess a low coefficient of thermal expansion. This characteristic assumes significance as cryogenic applications involve substantial temperature fluctuations. A high coefficient of thermal expansion can result in dimensional instability and stress within the material. Conversely, a low coefficient of thermal expansion mitigates these effects and maintains dimensional stability. Furthermore, the steel should demonstrate low thermal conductivity. Given that cryogenic applications often entail the transfer or storage of substances at extremely low temperatures, minimizing heat transfer is essential. A low thermal conductivity aids in maintaining the desired temperature and prevents unwanted heat exchange. This aspect is particularly critical in applications where precise temperature control is paramount, such as the storage of liquefied gases. In addition, the steel must exhibit excellent corrosion resistance. Cryogenic environments can be highly corrosive, necessitating the steel's ability to withstand the detrimental effects of corrosive substances that may be present. This attribute is particularly vital in applications involving the storage or transportation of cryogenic liquids or gases. Finally, the steel should possess good weldability. Welding is often necessary to join different components or sections of the steel in cryogenic applications. Therefore, ensuring the steel's weldability is crucial to establish strong and reliable joints. In summary, the requirements for special steel used in cryogenic applications encompass exceptional low-temperature toughness, a low coefficient of thermal expansion, low thermal conductivity, excellent corrosion resistance, and good weldability. Satisfying these requirements guarantees the steel's ability to withstand the harsh conditions and extreme cold of cryogenic environments while preserving its structural integrity and performance.

- Q:What are the different corrosion-resistant coatings for special steel?

- There are several different corrosion-resistant coatings available for special steel, each with their own unique properties and advantages. Some of the most common ones include: 1. Zinc Coating: Zinc coatings, such as galvanizing, are widely used to protect special steel from corrosion. The zinc layer acts as a sacrificial barrier, preventing the steel from coming into contact with corrosive elements. 2. Epoxy Coating: Epoxy coatings are a popular choice for corrosion protection due to their excellent adhesion, chemical resistance, and durability. They form a strong barrier that shields the special steel from moisture, chemicals, and other corrosive agents. 3. Polyurethane Coating: Polyurethane coatings provide exceptional resistance to abrasion, chemicals, and weathering. They are often used in harsh environments where the special steel is exposed to extreme conditions, such as offshore or marine applications. 4. Ceramic Coating: Ceramic coatings offer high-temperature resistance and excellent corrosion protection. They are commonly used in industries like aerospace and automotive, where the special steel needs to withstand extreme temperatures and corrosive environments. 5. Metal Coating: Metal coatings, such as nickel or chromium, are often applied to special steel to enhance its corrosion resistance. These coatings create a protective layer that prevents the steel from corroding by acting as a physical barrier. 6. Powder Coating: Powder coatings are applied electrostatically and then cured under heat, forming a hard and durable protective layer. They offer excellent corrosion resistance and can be customized in terms of color and texture. It is important to select the appropriate corrosion-resistant coating based on the specific requirements of the special steel and the environment in which it will be used. Factors such as temperature, exposure to chemicals or moisture, and the desired lifespan of the coating should all be considered when choosing the right coating.

- Q:What is the role of boron in special steel alloys?

- Boron plays a crucial role in special steel alloys, particularly in enhancing their mechanical properties and overall performance. One of the primary functions of boron is as a hardenability agent, meaning it improves the hardness and strength of the steel. This is achieved through the formation of boride particles, which act as strengthening agents within the microstructure. Additionally, boron aids in the refinement of the grain structure of steel, resulting in improved toughness and resistance to cracking. It promotes the formation of fine-grained microstructures, which in turn increase the steel's ability to withstand high temperatures, pressure, and wear. Moreover, boron assists in the solidification process of steel, reducing the risk of hot cracking during casting or welding. It lowers the melting point of steel, allowing for better fluidity and improved flowability during manufacturing processes. Furthermore, boron can also enhance the machinability of steel alloys, making them easier to work with and reducing tool wear. Overall, the addition of boron to special steel alloys significantly contributes to their strength, hardness, toughness, and resistance to various forms of degradation. Its role is vital in optimizing the performance and durability of these alloys in demanding applications such as automotive components, aerospace structures, and industrial machinery.

- Q:What are the applications of special steel?

- Special steel has a wide range of applications due to its unique properties and characteristics. It is commonly used in industries such as automotive, aerospace, construction, and manufacturing. Special steel is utilized for making high-strength components, tools, and machinery parts that require resistance to wear, corrosion, and extreme temperatures. Additionally, it is employed in the production of specialized equipment for oil and gas exploration, as well as in the medical field for surgical instruments and implants. Overall, special steel plays a crucial role in various sectors where durability, strength, and performance are essential.

- Q:What are the main advantages of using special steel in the oil and gas industry?

- The main advantages of using special steel in the oil and gas industry include its high strength, corrosion resistance, and ability to withstand extreme temperatures and pressures. Special steel is specifically designed and manufactured to meet the demanding requirements of the industry, ensuring reliable performance and longevity. It also offers excellent weldability, which is crucial for constructing pipelines and equipment used in oil and gas operations. Additionally, special steel's durability and resistance to fatigue make it ideal for withstanding the harsh conditions and environments encountered in the oil and gas sector.

- Q:What are the applications of special steel in the oil and gas manufacturing process?

- Special steel has various applications in the oil and gas manufacturing process. It is commonly used in the construction of pipelines, offshore platforms, and equipment for drilling and extraction. Special steel's high strength and corrosion resistance properties make it ideal for handling the demanding conditions encountered in oil and gas operations. Additionally, it is used in the production of valves, pumps, and other critical components that require durability and reliability to ensure efficient and safe processes in the industry.

- Q:How does special steel contribute to the telecommunications aftermarket industry?

- Special steel contributes to the telecommunications aftermarket industry by providing durable and high-quality components for various telecommunications equipment. This steel is used in the manufacturing of antennas, towers, cables, and other crucial parts, ensuring the reliability and longevity of the telecom infrastructure. Additionally, special steel's unique properties, such as corrosion resistance and high electrical conductivity, enhance the performance and efficiency of telecommunications systems, enabling seamless connectivity and better communication services.

- Q:What are the different defense grades of special steel?

- Special steel is a category of steel that is specifically designed to possess enhanced properties, such as increased strength, durability, and resistance to various environmental factors. When it comes to defense applications, special steel is often utilized to manufacture armor and protective components for military vehicles, aircraft, and naval vessels. These defense grades of special steel are classified based on their specific characteristics and performance levels. One of the most common defense grades of special steel is known as ballistic steel. Ballistic steel is engineered to provide exceptional resistance against ballistic threats, including bullets and shrapnel. It possesses high tensile strength and hardness, which allows it to withstand the impact and penetration of projectiles. Ballistic steel is categorized into several grades, such as MIL-A-46100, MIL-A-12560, and AR500, each offering different levels of protection against various types of ammunition. Another defense grade of special steel is known as blast-resistant steel. This type of steel is designed to withstand explosions and minimize the damage caused by shockwaves, fragmentation, and heat. It is commonly used in the construction of blast-resistant walls, doors, and windows for military bases, embassies, and critical infrastructure facilities. Blast-resistant steel grades are classified based on their ability to withstand different levels of explosive forces, with higher grades providing greater protection. Additionally, there are specialized grades of special steel used for anti-vehicle applications. These grades, such as Armox and Ramor, are engineered to resist the impact of heavy-caliber projectiles and explosive devices, making them suitable for manufacturing armored vehicles and personnel carriers. They provide a combination of high hardness, toughness, and energy absorption properties, ensuring the safety of military personnel on the battlefield. Overall, the defense grades of special steel are diverse and tailored to meet the specific requirements of different defense applications. They provide essential protection and ensure the safety of military personnel and equipment in challenging and hostile environments. The choice of the appropriate grade depends on the nature of the threat, the level of protection needed, and the specific design and performance criteria of the defense application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

0.4mm Thick PPGI Metal Sheet for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords