0.4mm Alloy Aluminum Sheet 3003 H14 from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

0.4mm alloy aluminum sheets 3003 H14

Alloy:3003

Temper: O H H12 H14 H18 H24

Thickness(mm):0.2-350mm

Width(mm):200-2300

Length(mm):800-13000

Delivery lead time: 20-25 days

Packing: wooden/veneer pallet, wooden/veneer case

Unit Price/Payment: FOB, CIF, CFR

Payment term: TT, LC at sight, Westen union

Country of origin: China

Certificate approved: ISO9001, SGS

MOQ: 2.0-2.5 metric ton per size

3003 Chemistry Composition | |||||||||

Element | Si | Fe | Cu | Mn | Mg | Cr | Ti | Zn | Al |

Standard Value | 0.6 | 0.7 | 0.05~0.20 | 1.0~ 1.5 | --- | --- | ---- | 0.10 | remainder |

3003 Aluminum is alloyed with 1.20% manganese, which increases the strength of 3003 over commercially pure aluminum (1100 series). 3003 has excellent workability, weldability, and good corrosion resistance. It is used for drawing, forming, spinning, fuel tanks, sheet metal works and other applications that require moderate strength for an aluminum with good weldability. H14 designates the temper, and means that 3003 has been strain hardened and partially annealed. In this condition, 3003 can be easily formed. Embossing or debossing 3003 in this temper should not strain or crack the plate.

The aluminum3003 ALUMINUM TREAD PLATE - Often referred to as diamond plate, it has the same properties of 3003H14, while excellent at resisting corrosion, and strong for light weight aluminum applications. The diamond trend pattern is slip-resistant and cosmetically appealing.

Applications:

· Cat Walks

· Heat Exchangers

· Food and Chemical handling equipment

· Truck and Trailer Roofing

· Floor Panels

Packaging & Delivery

| Packaging Details: | Export standard seaworthy fumigated wooden pallet only |

| Delivery Detail: | 15days |

- Q:Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation. Aluminum has good soundproofing properties due to its high density and ability to reflect sound waves. When used as a barrier or in combination with other sound-absorbing materials, aluminum sheets can effectively reduce noise transmission.

- Q:Can aluminum sheets be an alternative to wood in certain applications?

- Yes, aluminum sheets can definitely be an alternative to wood in certain applications. Aluminum has many advantages over wood, making it a popular choice in various industries. Firstly, aluminum is highly durable and long-lasting, as it is resistant to corrosion, rot, and pests. This makes it ideal for outdoor applications or areas with high moisture content. Additionally, aluminum sheets are lightweight, making them easier to handle and transport compared to wood. They also have high strength-to-weight ratio, meaning they can withstand heavy loads without compromising structural integrity. Furthermore, aluminum is a sustainable material as it can be recycled indefinitely without losing its properties. In contrast, wood requires cutting down trees, which has environmental implications. Aluminum sheets also offer design flexibility, as they can be easily shaped, bent, and formed into complex structures, allowing for creative and innovative applications. Moreover, aluminum has excellent thermal and electrical conductivity, making it suitable for applications where heat dissipation or electrical conductivity is important. Despite these advantages, it is important to note that wood still has its unique characteristics and benefits in certain applications. Wood creates a warm and natural aesthetic that aluminum cannot replicate, and it is often preferred in interior design or furniture manufacturing. Additionally, wood is a renewable resource and has excellent insulating properties, which can be advantageous in construction or insulation applications. Therefore, while aluminum sheets can be a great alternative to wood in many cases, the choice ultimately depends on the specific requirements and desired outcomes of the application.

- Q:why can't aluminum sheet burn after polishing?

- because aluminum will rapidly formulate dense oxide film once being exposed in air, oxide film will generate after polishing, it can't burn.

- Q:Can aluminum sheets be bent?

- Indeed, the bending of aluminum sheets is possible. Aluminum, being a remarkably pliable metal, can be effortlessly manipulated and molded through methods like bending, rolling, or folding. To achieve a particular angle or curve, the procedure for bending aluminum sheets entails the application of force onto the metal. This can be accomplished using specialized equipment like a brake press or through manual techniques. The adaptability of aluminum renders it a favored option for a variety of applications in the construction, automotive, and aerospace sectors, where bending or shaping is necessary.

- Q:I have a problem when machining aluminium in my machine shop. There are times when the machines aluminium surface turns yellowish (somtimes brown). I do not know what is the main cause of the problem. Is it due to the coolant used?

- Aluminum oxides may appear in different colors depending on hydration states and other variables. Look in a CRC Handbook of Chemistry Physics if available for aluminum compounds and their colors. The colors that you see may also have as much to do with the surface finish as the color of the material on the surface. A microscopically rough surface will appear dark next to a polished surface due to light scattering. I will agree with Ling in principle, but not on details. EDS detection limits on homogeneous samples can be better than 0.1%, although not so good for elements at the light end of the detection range. Current detectors can detect chlorine (a common culprit for aluminum discoloration) at about 0.1%. Your problem with detection and one that Ling has addressed previously may be that a thin film of contamination would not be easily detected by EDS. As Ling suggests, SIMS is a good technique for detecting thin films and low concentrations. The problem with SIMS in this case may be that the detection limits are too good and the technique cannot be quantified. SIMS would detect 2 ppm of chloride and you couldn't tell for sure whether it was 2 ppm, which is probably not an issue here, or 2000 ppm, which would be significant. I would suggest x-ray photoelectron spectroscopy (ESCA or XPS) as an alternative for further study. The technique will analyze thin films (20 A) and detection limits are good enough (about 0.1%). In addition, XPS will give you information about the compounds present, e.g. whether the oxygen is aluminum oxide, aluminum hydroxide, etc. Good Luck.

- Q:I am looking at buying a used 1983-84 Eldorado but have read some things about the reliability of the aluminum engine. Any thoughts? Thanks.

- 1984 Cadillac

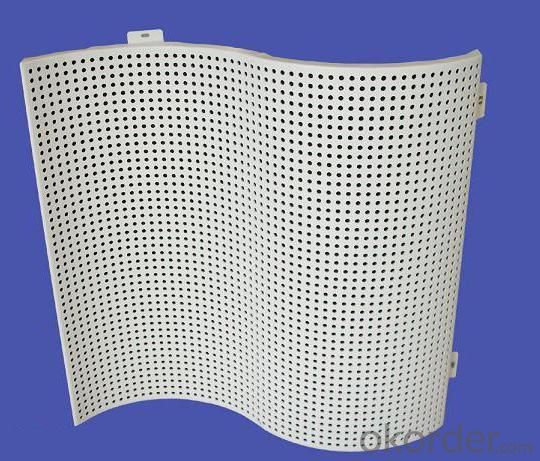

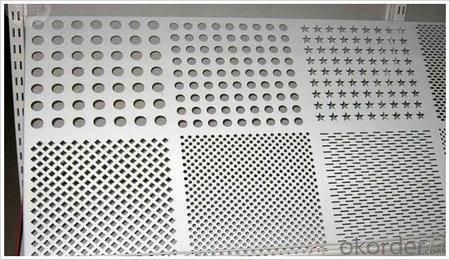

- Q:Can aluminum sheets be perforated?

- Yes, aluminum sheets can be perforated. Perforation is a process that involves punching holes or creating a pattern of holes in a material. Aluminum is a versatile and malleable metal that can be easily perforated using various methods such as punching, drilling, or laser cutting. Perforating aluminum sheets can serve multiple purposes such as allowing for airflow, reducing weight, enhancing aesthetics, or creating filtration systems. The size, shape, and arrangement of the perforations can be customized to meet specific requirements and design preferences. Overall, aluminum sheets can be effectively perforated to enhance their functionality and visual appeal.

- Q:What are the different manufacturing methods for aluminum sheets?

- Aluminum sheets can be manufactured using various methods, each possessing its own unique characteristics and applications. 1. Rolling, the most commonly employed method, involves passing large aluminum slabs through a series of rollers to reduce thickness and increase length. This process ensures consistent thickness and excellent surface finish. 2. Another method, extrusion, utilizes a heated aluminum billet forced through a die, resulting in a continuous sheet. Extrusion allows for the creation of complex shapes and profiles, making it suitable for applications in building construction and automotive components. 3. Casting involves pouring molten aluminum into a mold, allowing it to cool and solidify into a sheet shape. This method is often used for producing thicker sheets or those with specific alloy compositions. Casting offers unique properties and is prevalent in industries such as aerospace and defense. 4. Cladding entails bonding a thin layer of aluminum to another material like steel or composite materials. This combines the desirable qualities of aluminum, such as corrosion resistance and lightweight, with the strength and durability of the base material. Clad aluminum sheets find common use in construction, transportation, and electrical industries. 5. Powder metallurgy involves forming aluminum sheets from powdered aluminum particles. The powder is compacted into the desired shape and then sintered at high temperatures to fuse the particles together. This method is ideal for producing complex shapes and can improve mechanical properties. Considering the desired properties, application, and cost considerations, it is crucial to select the most appropriate manufacturing method for aluminum sheets based on the specific project requirements.

- Q:Can the aluminum sheets be used in food or beverage processing industries?

- Indeed, the food and beverage processing industries can utilize aluminum sheets. This non-toxic material is extensively employed in this field owing to its exceptional characteristics. Aluminum sheets boast corrosion resistance, light weight, and commendable thermal conductivity. These attributes render them perfect for a multitude of applications in the food and beverage processing industries, including food packaging, cooking utensils, storage containers, and beverage cans. Furthermore, aluminum proves to be an environmentally friendly choice as it is recyclable, thus amplifying its appropriateness for deployment in these sectors.

- Q:What are the common thicknesses of aluminum sheets used in aerospace applications?

- Aluminum sheets are commonly utilized in aerospace applications because of their lightweight and high strength properties. The thickness of these sheets can vary based on the specific needs of the fabricated component or structure. Aluminum sheets in aerospace applications typically have thicknesses ranging from 0.016 inches (0.4 mm) to 0.25 inches (6.35 mm). These thicknesses are chosen considering factors such as the desired strength-to-weight ratio, structural integrity, and the specific application or component being manufactured. Thinner aluminum sheets, with a thickness of 0.016 to 0.040 inches, are frequently used for lightweight structures, interior components, and non-critical parts. These thin sheets provide the necessary strength while keeping weight at a minimum. Thicker aluminum sheets are employed for more structural components. Typically, thicknesses between 0.040 and 0.125 inches are utilized for structural elements like floor panels, bulkheads, and wing ribs. These sheets offer enhanced strength and rigidity to support the aircraft's weight and handle the stresses experienced during flight. In certain cases, even thicker aluminum sheets ranging from 0.125 to 0.25 inches may be employed for heavy-duty structural components or areas requiring additional strength. These thicker sheets are used for critical parts like landing gear components, wing spars, and engine mounts to ensure the necessary structural integrity and load-bearing capability. It is important to note that these thickness ranges are general and may vary depending on the aircraft type, design specifications, and the specific application within the aerospace industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

0.4mm Alloy Aluminum Sheet 3003 H14 from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords