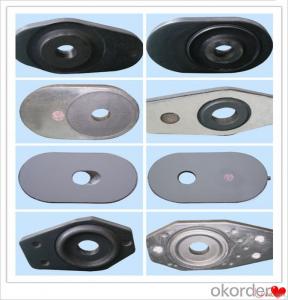

Steel End Plate

Steel End Plate Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleSteel End Plate Supplier & Manufacturer from China

Okorder.com is a professional Steel End Plate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Steel End Plate firm in China.Hot Products

FAQ

- Special steel contributes to the agricultural sector in several ways. Firstly, special steel is known for its strength and durability, making it an ideal material for manufacturing various agricultural machinery and equipment. This includes tractors, plows, harvesters, and irrigation systems, among others. These machines require robust and reliable components that can withstand the demanding conditions of agricultural work, and special steel provides the necessary strength and resistance to wear and tear. Additionally, special steel can be used to produce high-quality cutting tools that are essential in farming operations. Implements such as sickles, scythes, and pruning shears need to have sharp and durable blades to efficiently cut through vegetation. Special steel's hardness and strength make it a suitable material for manufacturing these tools, ensuring they retain their sharpness even after prolonged use. Furthermore, special steel can contribute to the agricultural sector by enabling the construction of sturdy and durable infrastructure. Agricultural buildings, storage facilities, and fencing often require strong and corrosion-resistant materials to withstand the elements and protect crops, livestock, and equipment. Special steel, with its resistance to rust and structural integrity, can be used in the construction of barns, silos, sheds, and fencing, providing long-lasting and reliable structures. In conclusion, special steel plays a crucial role in the agricultural sector by providing the necessary strength, durability, and corrosion resistance required for the manufacturing of machinery, cutting tools, and infrastructure. Its properties contribute to improved efficiency, productivity, and reliability in agricultural operations, ultimately benefiting farmers and the overall agricultural industry.

- Magnetic steel possesses several properties that make it suitable for various applications. It exhibits ferromagnetism, meaning it can be magnetized and holds a magnetic field strongly. This property enables it to attract and repel other magnetic materials. Magnetic steel also has high permeability, allowing magnetic flux to pass through it easily. It has a high saturation magnetization, meaning it can hold a strong magnetic field. Furthermore, magnetic steel demonstrates excellent mechanical strength, durability, and corrosion resistance, making it ideal for use in industries such as electrical engineering, automotive, and construction.

- Special steel plays a crucial role in the manufacturing of valves and pumps. Its exceptional properties such as high strength, corrosion resistance, and heat resistance make it an ideal material choice. Special steel ensures the durability and reliability of valves and pumps, enabling them to withstand harsh conditions, high pressure, and extreme temperatures. Additionally, the precise composition and mechanical properties of special steel allow for efficient fluid flow control and efficient energy transfer in valves and pumps, enhancing their overall performance.

- The common alloying elements in special steel are chromium, manganese, molybdenum, nickel, and vanadium.

- High-temperature alloy steel is used in the production of heat exchangers due to its exceptional resistance to high temperatures and corrosion. It allows heat exchangers to efficiently transfer heat between two fluids while maintaining structural integrity. The alloy steel's properties, such as high strength and thermal stability, ensure long-lasting performance and reliability in demanding industrial processes.

- The composition of special steel greatly affects its properties. By adjusting the amounts of elements like carbon, manganese, chromium, and nickel, the steel's hardness, strength, corrosion resistance, and heat resistance can be modified. Additionally, the presence of specific elements can also enhance other properties such as toughness, wear resistance, and machinability. Therefore, careful control of the composition allows manufacturers to tailor the steel's properties to meet specific requirements for different applications.

- The main factors affecting the heat resistance of special steel include its composition, microstructure, and processing techniques. The composition of the steel, particularly the presence of alloying elements such as chromium, nickel, and molybdenum, can greatly influence its ability to withstand high temperatures. Additionally, the microstructure of the steel, which is determined by factors like heat treatment and grain size, plays a significant role in its heat resistance. Finally, the processing techniques used during the manufacturing of the steel, such as forging or casting, can also impact its ability to withstand heat.

- Special steel plays a crucial role in the industrial machinery aftermarket industry by providing high-quality, durable, and customized components that are essential for repairing and maintaining machinery. Its unique properties, such as high strength, toughness, corrosion resistance, and heat resistance, enable the production of precision components that can withstand heavy industrial usage. This contributes to the efficiency, reliability, and longevity of machinery, reducing downtime and overall costs for businesses in the aftermarket industry.