Spte Tinplate

Spte Tinplate Related Searches

Printing Tinplate Sheet Tinplate Iron Packaging Tape Tinplate Material Tinplate Cover Standard Gauge Tinplate Tinplate Tea Set Mth Tinplate Set Circle Packaging Machinery Inc Tinplate Model TrainsHot Searches

Price Of Tinplate Tinplate Sheet Price Tinplate Price Per Ton Tinplate Stock Price Tata Tinplate Price List Tinplate Price Trend Tinplate Nse Share Price Tinplate Price Chart Tinplate Share Price Nse Tata Tinplate Share Price Tinplate Share Price Today Tinplate Share Price Bse Tinplate Price Tinplate Share Price Tinplate Cans Manufacturers Tinplate China Tinplate Stock Price Tata Tinplate Price List Tinplate Price Trend Tinplate Nse Share PriceSpte Tinplate Supplier & Manufacturer from China

Okorder.com is a professional Spte Tinplate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Spte Tinplate firm in China.Hot Products

FAQ

- Tinplate is coated to prevent corrosion through a process called electrolytic tinning. In this process, a thin layer of tin is electroplated onto the surface of the tinplate, creating a barrier between the metal and its environment. This tin coating acts as a sacrificial layer, which means that it corrodes instead of the underlying metal. This protective coating helps to prevent the tinplate from rusting and extends its lifespan.

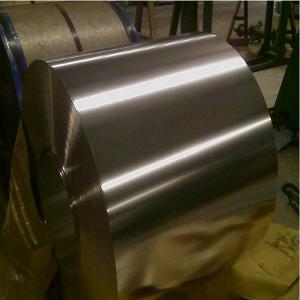

- Tin coating is typically applied to a steel substrate through a process known as electroplating. In this method, the steel substrate is first cleaned to remove any impurities, then it is immersed in an electrolyte solution containing tin ions. A direct current is then passed through the solution, causing the tin ions to be attracted to the steel surface and form a thin layer of tin coating. This process ensures uniform coverage and adherence of the tin coating to the steel substrate.

- Tinplate offers several benefits when used for coins. Firstly, tinplate is highly durable, making it resistant to corrosion and wear, ensuring the longevity of the coins. Additionally, tinplate is easily moldable, allowing for intricate designs and detailed engravings on the coin's surface. Moreover, tinplate is a cost-effective material, making it an affordable choice for coin production. Lastly, tinplate is also lightweight, making it convenient for handling and transportation.

- The main factors influencing the supply of tinplate are the availability and cost of raw materials such as tin, steel, and other alloys, the production capacity and efficiency of tinplate manufacturers, government regulations and policies, fluctuations in demand from industries such as packaging, automotive, and electronics, and global economic conditions and trade dynamics.

- Tinplate is commonly used in the marine industry for applications such as corrosion-resistant coatings for steel structures, manufacturing of storage tanks and containers, shipbuilding and repair, and as a protective barrier in marine electrical systems.

- Tinplate contributes to food safety by providing a protective barrier between the food and the metal surface, preventing the transfer of any harmful substances or contaminants. Additionally, tinplate helps to preserve the quality and freshness of the food by preventing exposure to air, moisture, and light, which can lead to spoilage.

- Tinplate is a type of steel coated with a thin layer of tin, which provides corrosion resistance and enhances its appearance. On the other hand, tin-free steel refers to steel that does not have a tin coating, making it more cost-effective but also less resistant to corrosion.

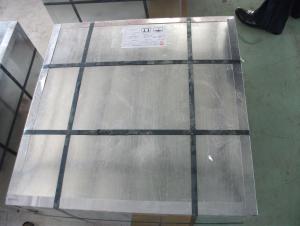

- Tinplate packaging provides a strong and durable barrier that helps protect products from breakage. The rigid nature of tinplate offers excellent resistance against external impacts, preventing the product from getting damaged during handling, transportation, or storage. Additionally, tinplate's ability to withstand compression and stacking ensures that the product remains intact even when subjected to pressure. Its protective qualities make tinplate packaging highly reliable in safeguarding products and reducing the risk of breakage.