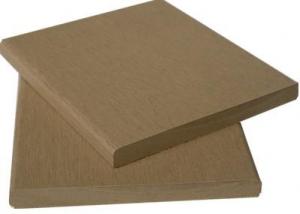

Masterclad Board

Masterclad Board Related Searches

Fiber Sheet For Roof Waterproofing Additive For Cement Render Stainless Steel Hot Tubs Stainless Steel Draining Board Aluminum Foil Hot Rail Hot Aluminum Foil Trick Pig Hot Water Bottle Cover Tartan Hot Water Bottle Cover Electric Hot Water Bottle Argos Funny Hot Water Bottle CoversHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Stainless Steel Tank For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Aluminum Coil Stock For Sale Used Foam Board Insulation For SaleMasterclad Board Supplier & Manufacturer from China

Okorder.com is a professional Masterclad Board supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Masterclad Board firm in China.Hot Products

FAQ

- It's expired. What color is it? It's better to have screenshots

- I checked the relevant information about electrode idle period narrative is not found, only the storage warehouse ventilation requirements. Electrode drying. No harmful gas and corrosive medium. The temperature 10-25 degrees, humidity fifty percent. To damp. Drug skin discoloration. Core rust after drying of the electrode to assess the quality of the performance indicators meet the requirements, can be assured.From the point of view of the situation (I used to put blind, for six years), medicine skin color. There are core electrode drying after rust still use, do not feel abnormal, (of course not weld inspection index). But there have been coating stripping or drying after stripping, can not use.Cast iron electrode used before heating up to 150 degrees, heat preservation 2 hours, and then use how much, how much can be used, or else there will be a lot of pores,

- 2.5, 3.2, 4, 1 kilograms of welding wire, how many branches?

- Carbon steel electrode 3.2 of a kilogram of about 32, 4 of a kilogram of 17. Stainless steel 3.2=34 root,.4.0=19 root,.2.5 forget

- What type of welding rod is used for welding 16MnD?

- 16MnD read as low as sixteen mn. Belong to sixteen Mn low temperature steel.Can useBrand: J507FeNi (model: E5018-G) basic electrode welding.The electrode belongs to a low hydrogen and sodium alloy structure steel powder welding rod. DC reverse connection. All position welding.It has good low temperature impact toughness. Used for welding of medium carbon steel and low temperature steel pressure vessel. Such as:16MnD, 16MnDR, etc..

- E43XX welding electrodes are often used in welding of steel structures, of which 43 is indicated

- Simply put, 43 means the tensile strength of deposited metal, 43Kgf/mm2, that is, 420MPa.

- Cast 308 pure nickel cast iron welding electrode. What shall be used for welding?

- Welded stainless steel.The electrode consists of two cores and coating composition. The electrode is coating in metal welding core (coating), uniform centripetal pressure applied to core. The electrode of different types, different cores. The core metal cored electrode, in order to ensure the quality and performance of the weld, there are strict rules on the contents of metal elements in the core, especially for harmful impurities (such as sulfur, phosphorus content, etc.) should be strictly restricted, better than the base metal. The electrode is metal cored coating called cores. The core is generally a certain length and diameter of the steel wire. When welding, the welding core has two functions: one is the conduction of the welding current, arc energy converted into heat, two cores melting as the formation of the weld filler metal and liquid base metal fusion.

- Why can't manual arc welding be performed with bare electrode?

- Please read the role of electrode coating. Medicine skin on the one hand, stable arc, on the one hand protect and + alloy role, there is no drug skin, welding rod can not continue stable combustion, molding is not good, poor quality

- What is the cause of partial magnetic blow?

- Equal distances are provided with double ground wires or multiple ground wires.

- Can 50Mn2 casting be welded with 507 electrodes?

- 50Mn2 is medium carbon steel, while J507 electrode is a low carbon component. If 507 electrodes are used to weld, the carbon content of the weld seam is lower, which will reduce the joint strength. Therefore, the welding of 50Mn2 steel with J507 welding rod can not guarantee the strength of the weld seam. It only applies to the welding of the weld when the strength of the joint is not high.