High Temperature Refractory Cement

High Temperature Refractory Cement Related Searches

Decorative Ceiling Plate For Light Fixture Ceiling Plate For Hanging Light Fiber Sheet For Roof Light Accessories For Cars Transformer For Light Fixture 42 White Ceiling Fan With Light Waterproofing Additive For Cement Render Bedside Table With Light Light Fixture With Chain Light Steel VillaHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Stainless Steel Tank For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Aluminum Coil Stock For Sale Steel Mesh Panels For SaleHigh Temperature Refractory Cement Supplier & Manufacturer from China

Okorder.com is a professional High Temperature Refractory Cement supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest High Temperature Refractory Cement firm in China.Hot Products

FAQ

- Which kind of refractory floor is easy to use? ?

- Since it is used in public places, fireproofing is quite important.

- How many kinds of fireproof materials are there in the market?

- Inorganic insulation materials basically can achieve the goal, such as glass wool, rock wool, and foam glass. The phenolic foam in the organic foam materials is special. Phenolic foam is not only good at insulation, but also good at compounding with steel and other materials to achieve A-level performance, and the A-level insulation materials are: rock(ore) wool, foam glass and inorganic thermal insulation mortar. Insulation materials with B1 combustibility mainly are: Phenolics, polystyrene granules, etc. The insulation materials of fire barrier zone can use such A-level materials as rock (ore) wool, foam glass, and inorganic thermal insulation mortar, etc.

- How long can gypsum board endure fire?

- Fire endurance refers to the fire-resistent limit of the whole system of light-gauge steel structure coupled with gypsum. It does nor merely refers to gypsum board. Fire endurance of the common gypsum board with the thickness of 9.5mm keeps 1.5 hours. Those gypsum board with the thickness of 12mm has a fire endurance of 3 hours.

- How should fireproof building materials be ranked?

- According to our national standard GB8624-97, the combustion performance of building materials are divided into the following levels: A class: Incombustible building materials: the material is almost incombustible. B1 class: Flame-retardant building materials: they are better in fire retardation. It is non-combustible when meeting open fire in the air or under high temperature, and it is difficult for the fire to spread quickly. Besides, when the fire source is removed, combustion stops immediately. B2 class: Combustible building material: It has certain fire retardation. In case of open fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as the spread to wooden pillars, timber roof truss, timber beams, wood stairs, etc. B3 class: Flammable building material: It has no fire retardant effect at all, but is highly flammable with high fire risk. Hope my answer can be accepted.

- What are the components of refractory clay?

- The component of refractory mortar comprises refractory powder, binders and admixtures. Almost all the refractory materials can be used as the powder to formulate refractory mortar. Ordinary refractory mortar is made from refractory chamotte powder, an appropriate amount of plastic clay as binding agent and plasticizer. It has low strength under normal temperature, but the ceramic formed under high temperature has a high strength. Refractory mortar which is formed with bonding material of hydraulicity, gas or thermal hardness is called chemical binding chamotte refractory mortar. It is hradened through chemical reaction before below the temperature of ceramic bonding formation.

- How to divide fire rating of decorating materials ?

- The combustion performance of building materials is divided into the following grades by the national standard GB8624-97: level A: incombustible building materials, almost no burning material. Level B1: Flame retardant building materials, such kind of materials are effective in flame retardance. It is difficult to fire in the air in the case of open flame or under high temperature, it is not easy to spread quickly, and when the fire source is removed , the fire stopped immediately. Level B2: combustible building materials. Combustible building materials are effective in flame retardance. It will immediately burst into flames in the air in case of fire or under high temperature, and it is inclined to lead to the spread of fire, such as wooden, wooden frame, beams, wood stairs,etc. Level B3: Flammable building materials: they have no effect in flame retardance, easy to burn, fire risk is very huge.

- Is it necessary for the frame of glass fireproof door to be crammed with fire-proof material?

- Close the door , and check if the gap is normal, whether the hole and the door leaf are in the same plane, and whether the door leaf has tendency to fall down. Fire resistance steel door——means that use a cold rolled steel sheet as door frame, door plank and framework, and stuff a door leaf with incombustible material.

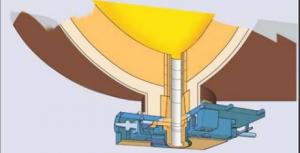

- What are the specific steps of stirring the steel ladle castable?

- Steps are as follows. 1 Compulsory mixer is used to stir the castable and bags, rope and other debris can not mix in the castable when stirred. 2, Castable should be unpacked on the scene. Stirred volume depends on the capacity of the mixer. Castable should be accurately measured and put into a blender. 3 The process of first dry mixing and then wet mixing is adopted. After the castable is added to the mixer, it is dryly mixed for 2 minutes, add about 5.2 to 5.5 percent of water and continue to add water while stirring. Water that is 80% of the total should be added, and then decide whether to continue to add or not depending on the consistence (noting that the water must be clean water and sewage can not be used). Then it is wetly mixed for 4 minutes and stirred for not less than 6 minutes at one time, until castable is even. In general, the bottom is slightly dry and the wall of the ladle is slightly dilute (the amount of water is only for reference). 4, The amount of water and mixing time should be controlled strictly when stirred to ensure that the needs of the consistency are met. If castable is too thin, it will seriously affect the quality of the material. The stirred volume, stirring time and water that is added should be consistent and they can not suddenly be thick or suddenly be thin. If the consistency does not meet the requirements, the castable should be put back to the mixer and stirred with appropriate water or dry materials. 5, It should be stirred evenly and casting should finish in 20 minutes, in order to avoid sclerosis, affecting structural strength of ladle lining 6, After each completion of construction, varieties of castable should be changed and the mixer should be cleaned 7, Stirring can stop in halfway. If the mixer breaks down and it can be repaired in a short time, some of the materials have to be removed before the machine is opened. If the machine can be repaired on time, castable refractory should all be removed.