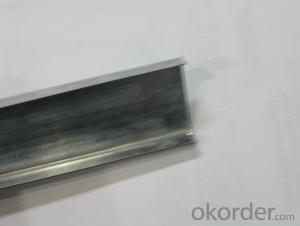

Galvanized Steel Beams

Galvanized Steel Beams Related Searches

Best Paint For Stainless Steel Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For Bbq Step Bit For Stainless Steel Sponge For Stainless SteelHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleGalvanized Steel Beams Supplier & Manufacturer from China

Okorder.com is a professional Galvanized Steel Beams supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Galvanized Steel Beams firm in China.Hot Products

FAQ

- What is the weight per metre of 250x250x9x14h steel, please? Do you have any relevant information? Thank you

- H - B - height; width; T1 web thickness; T2 flange thickness; R radius of H type steel said method is as follows: height H width B * * * T1 web thickness plate thickness T2, such as H type steel Q235B:200 * 200 * 8 * 12 for high 200mm wide web thickness 200mm 8mm, wide flange H type steel plate thickness 12mm, the grade is Q235B

- Indeed, when it comes to constructing stadiums, steel H-beams are widely utilized and considered appropriate for this purpose. These H-beams possess several advantages that render them an ideal selection for stadium construction. Primarily, they offer exceptional structural integrity and strength, enabling the construction of expansive areas and accommodating heavy loads required in stadiums. Consequently, this eliminates the need for excessive supporting columns, maximizing the seating capacity for spectators. Moreover, steel H-beams exhibit high durability and resistance to various environmental elements, such as severe weather conditions and seismic activities. As a result, the longevity and safety of the stadium structure are ensured. Additionally, the fabrication and assembly of steel H-beams can be easily accomplished, leading to an efficient and cost-effective construction process. Furthermore, the utilization of steel H-beams allows for design flexibility, empowering architects to create distinctive and visually appealing stadium structures. These beams can be employed for various purposes, including supporting roof structures, grandstands, and other elements within the stadium. In conclusion, steel H-beams are highly suitable for stadiums due to their strength, durability, versatility, and cost-effectiveness. They provide the necessary structural support while facilitating efficient construction processes and aesthetically pleasing designs.

- Using steel H-beams for construction offers several energy efficiency benefits. Firstly, steel is a highly sustainable material, as it can be recycled repeatedly without losing its strength. This reduces the need for extracting and manufacturing new steel, resulting in lower energy consumption and greenhouse gas emissions. Additionally, steel H-beams have a high strength-to-weight ratio, meaning they provide excellent structural support while requiring less material. This not only reduces the overall weight of the building, leading to energy savings during transportation and construction but also allows for more design flexibility and efficient space utilization. Furthermore, steel is a durable material that requires minimal maintenance and has a long lifespan, reducing the need for frequent replacements and associated energy consumption. Overall, the use of steel H-beams contributes to energy efficiency by minimizing resource consumption, optimizing structural performance, and reducing long-term maintenance needs.

- Steel H-beams are widely regarded as one of the strongest building materials available in the construction industry. The unique shape of the H-beam provides exceptional strength and structural integrity, making it highly suitable for various applications. Compared to other building materials such as wood, concrete, or aluminum, steel H-beams offer significant advantages in terms of strength. The high tensile strength of steel allows H-beams to withstand heavy loads and resist bending or warping under pressure, making them ideal for supporting large structures and heavy equipment. Moreover, steel H-beams have a higher strength-to-weight ratio compared to materials like wood or concrete. This means that steel can withstand greater loads while being relatively lighter in weight, making it easier to transport and install. The strength of H-beams also allows for longer spans between support points, reducing the need for additional columns or supports, thus maximizing space utilization in a building. In addition to their superior strength, steel H-beams also offer exceptional durability and longevity. Steel resists corrosion, rot, and pests, which can be common issues with materials like wood. This durability ensures that structures built with steel H-beams can withstand harsh weather conditions and require minimal maintenance over their lifespan. Overall, steel H-beams surpass other building materials in terms of strength, offering unparalleled structural integrity, higher strength-to-weight ratio, and greater durability. These characteristics make them a preferred choice for a wide range of construction projects, from high-rise buildings and bridges to industrial facilities and warehouses.

- Steel H-beams are fabricated using several common techniques, including hot rolling, welding, and cutting. The primary fabrication technique for producing steel H-beams is hot rolling. This involves heating a large steel billet and passing it through a series of rollers to shape it into the desired H-beam profile. Through this process, H-beams with consistent dimensions and excellent structural integrity are created. Welding is another crucial technique used in fabricating steel H-beams. It entails joining multiple steel plates or sections together to form the H-beam shape. Welding can be performed using various techniques, such as arc welding, MIG welding, or TIG welding, depending on the project's specific requirements. By creating a continuous and seamless connection between the different components, welding enhances the strength and rigidity of the H-beam. Cutting is also a widely employed technique in the fabrication of steel H-beams. It involves removing excess material to achieve the desired dimensions and shape. Various cutting methods, such as sawing, shearing, or plasma cutting, can be utilized. This process ensures precise and accurate shaping of the H-beam, meeting the required specifications. In summary, these fabrication techniques are vital for the production of steel H-beams as they guarantee their structural integrity, dimensional accuracy, and overall quality.

- Steel H-beams are generally faster to construct compared to concrete beams. This is primarily due to the nature of steel as a material, which allows for easier and faster fabrication and assembly. Steel H-beams can be prefabricated off-site, allowing for efficient mass production and faster delivery to the construction site. In contrast, concrete beams require more time for construction. The process involves multiple steps, such as formwork installation, pouring and curing of the concrete, and removal of the formwork. These steps take time to complete, and the curing process alone can take several days or even weeks, depending on the size and complexity of the beams. Moreover, steel H-beams are lighter in weight compared to concrete beams, making them easier to handle and install. This results in reduced labor requirements and shorter construction timelines. Additionally, steel beams can be easily adjusted or modified on-site, allowing for faster adjustments during the construction process. Overall, steel H-beams offer significant advantages in terms of construction speed compared to concrete beams. Their prefabrication capabilities, lighter weight, and ease of installation contribute to faster construction timelines, ultimately saving time and costs in the construction process.

- Steel H-beams are indeed appropriate for structures that experience high wind loads. These beams are specifically engineered to enhance the stability and strength of buildings, making them highly suitable for withstanding powerful winds. The distinctive shape of the H-beam enables it to evenly and efficiently distribute the load, thus minimizing the likelihood of structural failure. Moreover, steel possesses exceptional tensile strength, enabling it to endure the forces exerted by strong winds without distorting or collapsing. Consequently, utilizing steel H-beams in structures that face high wind loads guarantees the preservation of the building's integrity and safety.

- How should the steel H columns in the middle of the gable be placed?

- The surface of the mountain wall is wide and high, and the wind load is great. The wind load, the wall itself is unable to resist and needs the steel column to bear, so this column is called "wind resistant column"