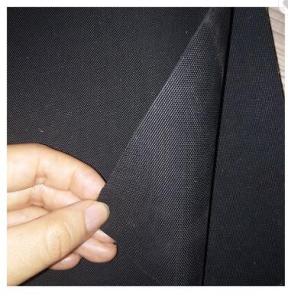

Containment Liners

Containment Liners Related Searches

Black Clay Roof Tiles Grey Clay Roof Tiles French Clay Roof Tiles Terracotta Clay Roof Tiles Clay Roof Shingles Prefabricated Geomembrane Liners Geocomposite Clay Liner Geomembrane Liners Gcl Liner Pond Liners BrisbaneHot Searches

Aluminum Diamond Plate For Sale Aluminum Diamond Plate Suppliers Diamond Plate Aluminum Near Me Aluminum Diamond Plate Near Me Aluminum Diamond Plate Nearby Diamond Plate Aluminum Lowe's Plastic Planter Liners Wholesale Plastic Planter Liners Wholesale Geocomposite Manufacturers Plastic Planter Liners Wholesale Geosynthetic Clay Liner CostContainment Liners Supplier & Manufacturer from China

Okorder.com is a professional Containment Liners supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Containment Liners firm in China.Hot Products

FAQ

- Some different types of earthwork products include soil, gravel, sand, crushed stone, clay, and fill dirt. These materials are commonly used in construction and landscaping projects to create foundations, embankments, roads, and drainage systems.

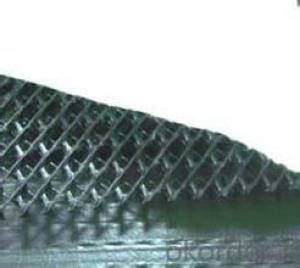

- Geogrids offer numerous benefits in slope reinforcement. Firstly, they enhance the stability of slopes by distributing the tensile forces applied to the soil, preventing soil erosion and potential slope failure. Secondly, geogrids improve the overall bearing capacity of slopes, allowing for increased load-bearing capacity and safer construction on steep slopes. Additionally, they help to reduce construction costs and time by reducing the amount of excavation and fill material required. Geogrids also promote vegetation growth, as they allow for better water drainage and retention, leading to improved ecological conditions. Overall, the use of geogrids in slope reinforcement provides cost-effective and sustainable solutions for slope stability and erosion control.

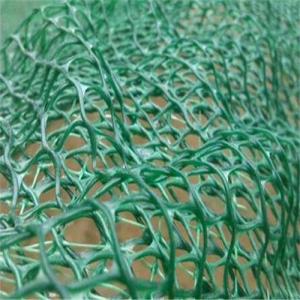

- Geosynthetic materials contribute to soil stabilization in agricultural applications by providing reinforcement and erosion control. They are often used in the form of geotextiles, geogrids, or geocells to improve soil strength, prevent erosion, and enhance drainage. These materials help in stabilizing slopes, retaining walls, and embankments, reducing the risk of landslides or soil erosion. Moreover, geosynthetics can improve soil moisture retention, promote root growth, and protect plants from weed growth, ultimately enhancing agricultural productivity.

- Geocells offer several advantages for load support applications. Firstly, they provide a cost-effective solution as they are made from lightweight materials and require minimal construction equipment. Additionally, geocells are highly versatile and can be easily customized to fit various site conditions and load requirements. They also provide excellent stability and load distribution by confining and reinforcing infill materials, resulting in enhanced load-bearing capacity. Geocells are also environmentally friendly, as they are typically made from recyclable materials and contribute to sustainable construction practices.

- Some advantages of using geotextile tubes for sediment dewatering include: 1. Cost-effectiveness: Geotextile tubes are generally more cost-effective compared to other sediment dewatering methods. They require less equipment and labor, resulting in lower overall project costs. 2. Efficient dewatering: Geotextile tubes have a high dewatering efficiency, allowing for the separation of water from sediment quickly and effectively. This leads to faster project completion and reduced downtime. 3. Environmental friendliness: Geotextile tubes offer an environmentally friendly solution for sediment dewatering. They minimize the release of sediment-laden water into surrounding water bodies, reducing the risk of water pollution and protecting aquatic ecosystems. 4. Versatility: Geotextile tubes can be used in various sediment dewatering applications, including shoreline protection, beach nourishment, and land reclamation. They can accommodate different types of sediments, making them a versatile solution for various projects. 5. Minimal space requirements: Geotextile tubes require minimal space for installation, making them suitable for projects with limited available space. They can be easily stacked or arranged to optimize the dewatering process without occupying large areas. Overall, geotextile tubes offer numerous advantages in terms of cost, efficiency, environmental impact, versatility, and space requirements, making them a popular choice for sediment dewatering projects.

- One of the key benefits of using geomembranes for landfill caps is their ability to provide a highly effective barrier against the escape of contaminated leachate and gases from the landfill. These impermeable liners prevent the migration of harmful substances into the surrounding environment, protecting groundwater and nearby ecosystems. Additionally, geomembranes offer durability and longevity, withstanding the harsh conditions of landfills and ensuring long-term containment. This helps in reducing maintenance costs and the need for frequent repairs. Moreover, geomembranes are relatively easy to install and can be customized to fit specific landfill designs, offering flexibility and efficiency. Overall, the use of geomembranes as landfill caps promotes environmental sustainability and safeguards public health.

- Geosynthetic materials are used in athletic field construction to enhance the stability, drainage, and durability of the playing surface. These materials, such as geotextiles, geogrids, and geomembranes, are installed underneath the turf or natural grass to provide reinforcement, prevent soil erosion, and improve water management. They help to maintain a consistent and level playing surface, reduce the risk of injuries, and extend the lifespan of the athletic field.

- Yes, there are earthwork products specifically designed for oil and gas projects. These products are tailored to meet the specific needs of the industry, such as erosion control, containment, and stabilization solutions for the construction and maintenance of oil and gas infrastructure. They are designed to withstand harsh environmental conditions and ensure the safety and efficiency of oil and gas operations.