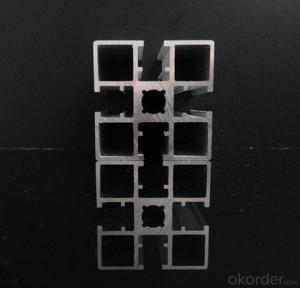

Aluminum Extrusion Framing

Aluminum Extrusion Framing Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Max Temp For Aluminum Foil Aluminum Foil For Key Fob Aluminum Foil For Hair FrizzHot Searches

Inverter Size For Solar System Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale Solar Panel Inverter Size Large Size Aluminum Foil Aluminum Foil Market Size Solar Inverter Market Size Solar Inverter Size Chart Solar Inverter Size Aluminum Channel Stock Sizes Sheet Metal Roofing Prices Metal Roof Tiles Prices Metal Furniture Company Type C Fuse Type C Sheetrock Geomembrane Market Size Geogrid Aperture Size Stock Price For AluminumAluminum Extrusion Framing Supplier & Manufacturer from China

Okorder.com is a professional Aluminum Extrusion Framing supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Aluminum Extrusion Framing firm in China.Hot Products

FAQ

- Aluminum profiles are a popular choice for construction due to their range of safety features. They are both lightweight and durable, making them easy to handle and install while still providing structural integrity. This reduces the risk of accidents or injuries during the construction process. Furthermore, aluminum profiles are non-combustible, meaning they do not contribute to the spread of fire. This is crucial for ensuring the safety of occupants and minimizing fire-related hazards. In addition, aluminum profiles have excellent corrosion resistance properties. They are naturally resistant to rust and decay, allowing them to withstand harsh environmental conditions and maintain their structural integrity over time. This is particularly important in coastal or humid areas where corrosion risk is high. Moreover, aluminum profiles can be designed to incorporate safety features such as non-slip surfaces or grooves for enhanced grip and stability. This is especially beneficial in applications where slip and fall accidents may occur, such as staircases or walkways. Additionally, aluminum profiles offer excellent electrical conductivity, making them advantageous for electrical installations. Their high thermal conductivity helps dissipate heat efficiently, reducing the risk of overheating or electrical malfunctions. Lastly, aluminum profiles are recyclable, aligning with sustainable construction practices and contributing to waste reduction and environmental impact. In conclusion, the safety features of aluminum profiles in construction, including their lightweight yet durable nature, non-combustibility, corrosion resistance, ability to incorporate non-slip surfaces, excellent electrical conductivity, and recyclability, make them a safe and sustainable choice for construction projects.

- Aluminum profiles commonly utilize various types of gaskets. Let's explore a few examples: 1. EPDM Gaskets: Crafted from a synthetic rubber material, EPDM gaskets excel in withstanding weathering, UV radiation, and ozone exposure. They are frequently employed in outdoor scenarios that demand a secure seal and resilience against harsh environmental conditions. 2. Silicone Gaskets: Renowned for their exceptional temperature resistance, silicone gaskets are a preferred option for applications involving extreme heat or cold. They also exhibit favorable resistance to chemicals and UV radiation, rendering them suitable for a wide array of industrial and commercial uses. 3. PVC Gaskets: Composed of a plastic material, PVC gaskets are extensively used due to their remarkable resistance to chemicals, oil, and moisture. They commonly find application in situations necessitating a tight seal, such as doors, windows, and architectural uses. 4. Neoprene Gaskets: Neoprene gaskets are constructed from a synthetic rubber material that offers commendable resistance to oils, chemicals, and weathering. They are frequently employed in machinery and equipment, where both sealing and vibration dampening are required. 5. Nitrile Gaskets: Nitrile gaskets, also known as Buna-N gaskets, are composed of a synthetic rubber material that boasts outstanding resistance to oils, fuels, and solvents. They find common use in automotive and industrial settings where resistance to oil and fuel is critical. These examples are merely a snapshot of the diverse gasket options available for aluminum profiles. The choice of gasket hinges upon the specific requirements of the application, encompassing desired sealing level, environmental conditions, and chemical compatibility.

- Indeed, aluminum profiles have the capability to be utilized in the manufacturing of material handling equipment. These profiles possess properties such as being lightweight, resistant to corrosion, and exhibiting a high strength-to-weight ratio, thus rendering them suitable for the construction of diverse components in material handling equipment. By means of these profiles, frames, support structures, conveyor systems, and other parts of material handling equipment can be effortlessly customized and assembled. Moreover, aluminum profiles provide design flexibility, enabling convenient modifications or additions to the equipment in accordance with specific requirements.

- Yes, aluminum profiles are compatible with glass. Aluminum frames are commonly used in the construction industry to hold and support glass panels in windows, doors, and other architectural applications. The lightweight, durable, and corrosion-resistant properties of aluminum make it an ideal material for framing glass.

- Aluminum profiles possess exceptional resistance against termites and insects, unlike wood that is vulnerable to termite infestations and insect harm. Being a nonporous substance, aluminum fails to offer nourishment to these bothersome creatures. Moreover, aluminum profiles are commonly shielded with safeguarding finishes such as powder coating or anodizing, reinforcing their resistance to termites and insects. Consequently, aluminum profiles emerge as a robust and enduring alternative for a wide range of applications, including window frames, door frames, and other construction endeavors where the menace of termite or insect damage lingers.

- What kind of self tapping screw can attack aluminum profile?

- Self tapping screws are used for connecting between thin metal plates. When connecting to the connecting piece for the threaded hole, then tapping screws into the threaded hole of the connecting piece. Because of the self tapping screw thread surface has higher hardness (more than 45HRC), the attack a thread in the threaded hole of the connecting piece, thereby forming a connection.Aluminum material than steel soft, generally in accordance with GB screws can be of aluminum, is recommended to hit bottom hole in the needed position.The following is the national standard for self tapping screws:GB/T15856.1-2002 cross recessed countersunk head tapping screws, material: 20Mn 15MnBGB/T15856.2-2002 cross recessed countersunk head drilling self tapping screw, material: 20Mn 15MnBGB/T15856.3-2002 cross recessed semi countersunk head drilling self tapping screw, material: 20Mn 15MnB

- Yes, aluminum profiles can be commonly used in the construction of curtain walls. Aluminum offers durability, lightweight properties, and excellent corrosion resistance, making it a popular choice for curtain wall systems. Additionally, aluminum profiles can be easily fabricated and installed, allowing for flexibility in design and efficient construction processes.

- What kinds of profiles are made of aluminium alloy windows?

- Very simple outline of the material: square tube (Fang Tiao), winger, on the slide, down the inner frame of the material: hook enterprises, light enterprises, the upper cross, lower cross