Air Powered Hydraulic Cylinder

Air Powered Hydraulic Cylinder Related Searches

Air Fryer With Aluminum Foil Aluminum Foil In The Dryer Aluminum Foil In Air Fryer Aluminum Foil In A Microwave Grill Corn In Aluminum Foil Aluminum Foil In Your Toilet Aluminum Foil In Oven Bottom Wrap Grill In Aluminum Foil Aluminum Foil In Your Shoes Grill Fish In Aluminum FoilHot Searches

Stainless Steel Supply Near Me Steel Girder Cost Stainless Steel Tubing Near Me Stainless Steel Welder Near Me Stainless Steel Shop Near Me Stainless Steel Welders Near Me ppr pipe manufacturers in saudi arabia ppr pipe price philippines Wholesale UPVC Pipe Price Philippines ppr pipes price list philippines Buy Sheet Plastic polypropylene pipe specifications White Plastic Folding Chairs Wholesale Black Plastic Plant Pots Wholesale ppr type 3 Plastic Flower Buckets Wholesale Wholesale Plastic Folding Chairs Wholesale Plastic Hanging Baskets Plastic Planter Liners Wholesale Air Pump For Aquarium PriceAir Powered Hydraulic Cylinder Supplier & Manufacturer from China

Okorder.com is a professional Air Powered Hydraulic Cylinder supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Air Powered Hydraulic Cylinder firm in China.Hot Products

FAQ

- Aluminum pipes and steel pipes have distinct differences in terms of their properties and applications. Firstly, aluminum pipes are much lighter than steel pipes, making them more convenient for transportation and installation. Due to their lightweight nature, aluminum pipes are commonly used in industries where weight reduction is crucial, such as aerospace and automotive. On the other hand, steel pipes are much heavier, which makes them suitable for applications that require high strength and durability, such as construction and infrastructure projects. Secondly, aluminum pipes have excellent corrosion resistance, especially when exposed to the atmosphere. This makes them suitable for outdoor applications where they are exposed to moisture and other elements. Steel pipes, on the other hand, are prone to corrosion and require additional coatings or treatments to protect against rust and deterioration. Thirdly, aluminum pipes have higher thermal conductivity compared to steel pipes. This property makes them ideal for applications that require efficient heat transfer, such as in HVAC systems or heat exchangers. Steel pipes, on the other hand, have lower thermal conductivity, but they offer higher resistance to fire, making them suitable for applications where fire protection is essential. Lastly, cost is an important factor when comparing aluminum pipes to steel pipes. Aluminum pipes tend to be more expensive than steel pipes due to the higher cost of raw materials and manufacturing processes. However, their long-term maintenance costs can be lower due to their corrosion resistance and lightweight properties, which can result in reduced labor and transportation costs. In summary, aluminum pipes and steel pipes have different properties and applications. Aluminum pipes are lighter, have better corrosion resistance, higher thermal conductivity, and are suitable for industries that require weight reduction. Steel pipes, on the other hand, offer higher strength, durability, fire resistance, and are commonly used in construction and infrastructure projects. The choice between aluminum and steel pipes ultimately depends on the specific requirements of the application and the trade-offs between cost, weight, strength, and other factors.

- Which is better, titanium alloy or high pressure aluminium tube?

- In addition, other aspects are titanium alloy victory over aluminum alloy, so to answer this question,

- Yes, aluminum pipes can be used for water treatment plants. Aluminum pipes are commonly used in water treatment plants due to their corrosion resistance, lightweight nature, and durability.

- Indeed, underground cable conduits can utilize aluminum pipes. The lightweight properties, remarkable resistance to corrosion, and lasting durability of aluminum make it a favored option for conduit applications. It effectively shields cables and electrical wiring from external factors like moisture, chemicals, and physical harm. Furthermore, aluminum pipes are renowned for their effortless installation and adaptability, rendering them appropriate for various underground cable setups. Nevertheless, it is crucial to ensure that the aluminum pipes undergo proper coating or treatment to avert any potential galvanic corrosion that may occur when they come into contact with other metals or soil.

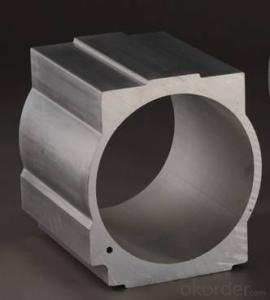

- Extrusion, a well-known process, is employed in the manufacture of aluminum pipes. This process involves the passage of a heated aluminum billet or log through a specifically shaped die, resulting in the creation of a desired cross-sectional shape. The initial stage of the manufacturing process entails the careful selection of a high-quality aluminum alloy. Subsequently, the alloy is subjected to heating in a furnace, usually at temperatures ranging from 750 to 950 degrees Fahrenheit (400 to 500 degrees Celsius). This heating renders the material malleable and facilitates ease of shaping. Upon reaching the desired temperature, the aluminum billet is moved to the extrusion press. This press comprises a chamber for billet placement and a ram that exerts pressure to propel the billet through the die. The final shape of the pipe is determined by the die. During the billet's passage through the die, it undergoes plastic deformation, adopting the shape of the die opening. The application of high pressure by the ram ensures precise control over the pipe's dimensions and surface finish. Following extrusion, the aluminum pipe is subjected to cooling in either a water bath or an air cooling system. This cooling process leads to the hardening and stabilization of the pipe's shape. Subsequently, the pipe is cut to the desired length, using commonly a saw or other cutting tools. The concluding step encompasses any necessary finishing processes, such as straightening, deburring, or surface treatment. These processes are essential in guaranteeing that the aluminum pipe fulfills the required specifications and quality standards. Overall, the extrusion process enables the efficient and cost-effective production of aluminum pipes, characterized by consistent dimensions and exceptional mechanical properties. Consequently, aluminum pipes have gained popularity across various industries, including construction, automotive, aerospace, and plumbing.

- What are the so-called "aluminum tubes" and "copper aluminum tubes" in air conditioners? Is it the pipe in the outer machine, or the connecting pipe between the outside machine and the inner machine?What materials are used in general external machines? For example, Panasonic, Midea, GREE, Haier, Changhong, CHIGO, Galanz, what are these materials used?

- Said is the internal and external machine connecting pipe, in the current, all the air conditioning and internal and external machines are also used in copper pipe, but there are some brands of internal and external machine connecting pipe into aluminum tube

- Yes, aluminum pipes can be used for wastewater pumping stations. Aluminum is a durable and corrosion-resistant material that can withstand the harsh conditions and chemicals present in wastewater. Additionally, aluminum pipes are lightweight and easy to install, making them a suitable choice for wastewater pumping stations.

- Aluminum pipes are known for their excellent performance in extreme temperatures. They have a high melting point of around 660 degrees Celsius, which makes them resistant to heat. This enables them to withstand high temperatures without deformation or structural damage. Additionally, aluminum has a low coefficient of thermal expansion, meaning it does not expand or contract significantly when exposed to extreme temperature changes. This property allows aluminum pipes to maintain their shape and structural integrity in both hot and cold conditions. Moreover, aluminum is a good conductor of heat, which allows it to dissipate and transfer heat effectively, preventing the pipes from overheating. Overall, aluminum pipes are highly reliable and perform exceptionally well in extreme temperature environments.