Acclimate Laminate Flooring

Acclimate Laminate Flooring Related Searches

H S Code For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Step Bit For Stainless Steel Led Floor Lamps For Home Led Light For Chandelier Hot Water Bags For Pain Relief Shade Cover For Solar Inverter Led Bulbs For Spotlights Led For Cannabis GrowingHot Searches

Steel Mesh Panels For Sale Cheap High Tea Sets For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Large Led Screens For Sale 1/4 Aluminum Plate For Sale H4 Led Headlight Bulbs For Sale Air Pump For Aquarium Price Inverter Size For Solar System Solar Edge Inverter For Sale 5kw Solar Inverter For Sale Printed Solar Cells For Sale Aluminum Round Stock For SaleAcclimate Laminate Flooring Supplier & Manufacturer from China

Okorder.com is a professional Acclimate Laminate Flooring supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Acclimate Laminate Flooring firm in China.Hot Products

FAQ

- My home is a solid wood floor, in the time of moving the furniture accidentally knocked off the floor layer of skin, it is difficult to see how to repair?

- Part of the repair of the destruction of the first need to replace the solid wood floor destroyed, and then completely removed. In practice, using the tool to replace the solid wood floor at the short side cut out a gap, then saw the need to replace the sawn wood floor surface, and then will be divided into small pieces of wood floor removed, but this process to ensure that does not damage the surrounding wood floor. After the removal of the solid wood floor, but also to clean up around the glue, to ensure that the cleaning of the tenon and groove easy to install. If the cleaning is not complete, the seam will be uneven or lax. In the processing of glue, can use a new sliding tenon piece of wood floors in the interface on the back and forth, find out and remove the residual glue, to ensure the restoration of the appearance of solid wood flooring.

- I had planned on installing solid hardwood floors in my house and now I found an engineered hardwood floor that I would like to put in instead. Will this cut my installation costs at all and by how much?? Thanks :)

- No. Typically, engineered install costs just as much as solid. It requires the same tools and the same amount of time to install.

- Is it safe to burn engineered hardwood flooring?

- it should be fine, most resins thes day and coating are none toxic. they dont allow to sell them anymore because of the ozone. it doesnt have lead in it like it used too. if your cold- burn it!!

- Advantages and disadvantages of solid wood flooring

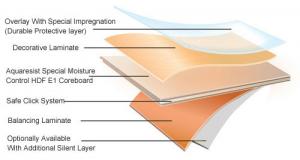

- Stability: solid wood floor of its wood fiber unidirectional and tree core and tree edge of the tree age is different, resulting in different levels of wood density of wood, so the plate caused by the thermal expansion coefficient is different and easy to deformation. In the case of dehydration easy to sew. Strengthen the production process of the floor is wood waste processing into powder, add glue, pressed into high density plate under high temperature and pressure, and then paste the computer printing decorative paper, then coated with three two aluminum oxide coatings and wear resistant materials, finally processed into what we see shape. Strengthening plate stability is good, but because of its substrate is high density board, heat and moisture to the whole swell, if left in the installation of the contraction joints of small, easily arching, and the floor is afraid of water, water easily after expansion, not a good deal. Multi layer solid wood floor, the production process is to cut wood veneer, and then according to the wood grain crisscross with resin glue hot pressing molding. Because the structure is arranged in a crisscross pattern characteristics between the layers contain each other, so as to overcome the above wood heat expansion coefficient of eighty-five percent, the deformation is small, and the substrate core board is the selection of Eucalyptus wood is loose, the pores of wood between the loose stress can also be partially offset by an expansion of wood shrink. So its stability is much stronger than other floors.

- Our house is a 1966 sub floor fondation, and there is original oak hardwood through out most of the house. So far, we have refinished the floors in two rooms just by sanding, conditioning and finishing with a clear coat--no stain and they're beautiful! Unfortunately, a previous owner did the unthinkable and installed engineered hardwood over the real hardwood in the front entry and two hallways. The engineered wood is ugly in comparison, and we can tell that the beautiful oak is underneath the glued down engineered flooring. Is there any chance the real wood could be salvaged if the engineered is removed, and if so, what would be the best and most economical way?

- Ya there is a chance.Pull off any trim on top of the floor in one of the areas-reducers,base board,1/4 round etc,with a pry bar try prying up a section(the begining of hallway would be a place to try).More than likely the engineered flooring is a toungue and groove or snap lock type,which is glued at the seams,and there is a underlayment of some sorts,tar paper or a foam backer.If thats the case then it will come up in big sheets,the pull and fold technique works about the best for me. Good luck

- Which is the best between engineered hardwood floors and natural hardwood floors?

- I prefer solid real hardwood flooring. In my opinion the finish on site solid floors look the best when completed.

- These problem areas are seriously bare wood. Is there any way to repair these problem areas with wax or something? A DIY link with pictures would be the best answer to my question.

- If your floors are truly engineered they are 3/8 plywood with a very thin (1/16 ) veneer over the plywood.If this is the case then there is nothing that you can do but replace...sorry, you have worn through the veneer.

- Can a finishing nail gun be used to install 3/8 engineered hardwood?

- It is best to use a flooring stapler. Bostich makes a stapler that is especially for installing engineered wood. Use the finish nailer would probably it hard for the rows to go together.