Stainless Steel Sheets 2B BA finish 201 304 316 430

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Stainless Steel Sheets 2B BA finish 201 304 316 430

Product name | stainless steel sheet 2b ba finish 201 304 316 430 |

Specification | Thickness: Cold rolled: 0.3-3mm, Hot Rolled: 3-120mm Customized sizes are accepted |

Standard | ASME, ASTM, EN, BS, GB, DIN, JIS, etc |

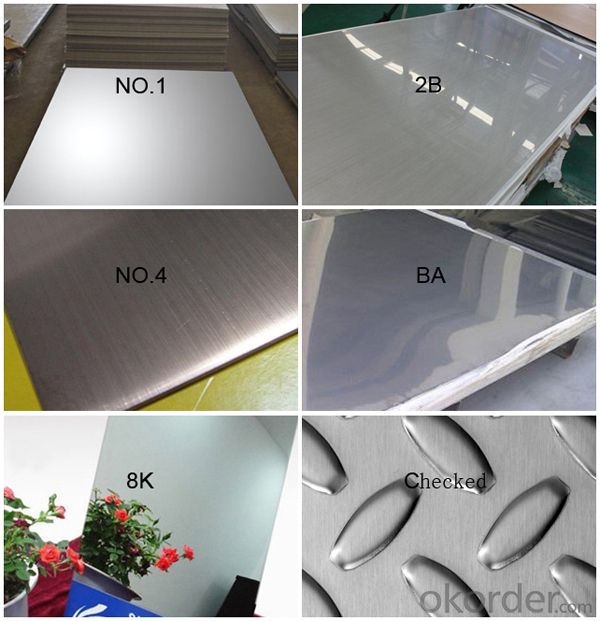

Finish | NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish and so on |

Material | 201, 202, 304, 304L, 310S, 316, 316L, 410, 420, 430, 441, 800H, 904L |

Technical treatment | Cold Rolled, Hot Rolled |

Port of Loading | Tianjin, Shanghai, Ningbo, Guangzhou |

Terms of Delivery | FOB, CFR, CIF, CNF |

Terms of Payment | L/C, T/T (30% deposit) |

Packing | Standard export sea-worthy packing |

Delivery time | Within 7-15 days after receive 30% deposit or as your requirement |

Finished Products

Surface Finished | Characteristics | Application |

BA | Bright heat treatment after cold rolling. | Kitchen utensil, Kitchen ware, Architectural purpose. |

2B | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to more brighter and smooth surface. | General application medical instruments, Tableware. |

NO.1 | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface. | Chemical industry equipment, Industrial tanks. |

8K(mirror) | A mirror-like reflective surface by polishing with finer abrasives over 800 mesh. | Refletor, Mirror, Interior- Exterior decoration for building. |

Hair Line | Finished by continuous linear polishing. | Architecture industries, Escalators, Kitchen ware, Vehicles. |

Packaging & Shipping

Packaging:All products are packaged according to the Standard export packing.In order to prevent friction damage and water erosion and so on.

Shipping: Ocean transportation,land transportation or air transportation.

- Q:What are the advantages of using stainless steel sheets in the medical industry?

- Using stainless steel sheets in the medical industry offers several benefits: 1. Maintaining Hygiene and Cleanliness: Stainless steel's non-porous nature makes it easy to clean and disinfect, making it an excellent option for medical equipment, surgical instruments, and hospital furniture. It resists bacteria, mold, and other pathogens, ensuring a hygienic environment. 2. Ensuring Longevity and Durability: Stainless steel can withstand harsh conditions, including high temperatures, humidity, and corrosive substances. This durability extends the lifespan of medical equipment and instruments, reducing the need for frequent replacements. 3. Providing Strength and Safety: Stainless steel sheets offer exceptional strength and structural integrity, making them suitable for applications that require resistance to impact and pressure. This is crucial in the medical industry, where instruments and equipment are constantly utilized and handled. 4. Resisting Stains and Corrosion: Stainless steel is highly resistant to stains and corrosion, even in aggressive environments. This property is essential in medical facilities where exposure to various chemicals and liquids is common. The resistance to corrosion ensures that stainless steel sheets remain intact and do not release harmful substances into the environment. 5. Enhancing Aesthetic Appeal: Stainless steel sheets have a sleek and modern appearance that contributes to the overall aesthetic appeal of medical equipment and instruments. This creates a positive impression on patients, instilling confidence in the quality and cleanliness of the medical facility. 6. Promoting Recyclability: Stainless steel is a sustainable material that can be recycled without any loss in quality. This reduces the environmental impact of the medical industry by minimizing waste and conserving resources. In conclusion, stainless steel sheets offer advantages such as hygiene, durability, strength, resistance to stains and corrosion, aesthetic appeal, and recyclability. These qualities make stainless steel a reliable and cost-effective choice for medical equipment, instruments, and other applications in healthcare settings.

- Q:What are the benefits of using etched stainless steel sheets in signage?

- There are several benefits of using etched stainless steel sheets in signage. Firstly, etched stainless steel sheets are extremely durable and long-lasting. Stainless steel is known for its resistance to corrosion, rust, and fading, making it ideal for outdoor signage that is exposed to harsh weather conditions. Secondly, etched stainless steel sheets offer a sleek and professional appearance. The process of etching allows for intricate designs, logos, and text to be permanently engraved onto the surface of the stainless steel. This creates a high-end and visually appealing finish that adds a touch of sophistication to any signage. Furthermore, etched stainless steel sheets are highly customizable. They can be tailored to meet specific design requirements, making them suitable for a wide range of signage applications. Whether it is for architectural signage, company logos, directional signs, or wayfinding systems, etched stainless steel sheets can be designed to suit any style or branding. Moreover, stainless steel is easy to clean and maintain. It can be wiped down with a cloth or cleaned with mild soap and water, ensuring that the signage remains in pristine condition for an extended period. This low maintenance requirement is particularly advantageous for outdoor signage, where regular cleaning may be necessary. Lastly, etched stainless steel sheets offer excellent visibility. The engraved designs on the stainless steel surface can be filled with paint or other materials to create contrast, making the signage highly visible even from a distance or in low light conditions. This enhanced visibility is crucial for effective signage, as it ensures that the intended message or information is easily communicated to the target audience. In conclusion, the benefits of using etched stainless steel sheets in signage include durability, a professional appearance, customization options, easy maintenance, and excellent visibility. These advantages make etched stainless steel sheets a popular choice for signage applications in various industries.

- Q:Can stainless steel sheets be used in high-pressure applications?

- Stainless steel sheets are indeed applicable in high-pressure scenarios. Renowned for its remarkable resistance to corrosion and impressive strength, stainless steel is suitable for a variety of industrial uses, especially those involving high-pressure conditions. Its exceptional strength enables it to endure the force exerted by high-pressure fluids or gases without distorting or breaking. Moreover, stainless steel sheets can be shaped and sized as desired, facilitating their utilization in a wide array of high-pressure applications such as pressure vessels, pipelines, hydraulic systems, and heat exchangers. All in all, stainless steel sheets are a dependable and long-lasting option for high-pressure circumstances due to their inherent strength and corrosion resistance characteristics.

- Q:What is the difference between cold rolled and hot rolled stainless steel sheets?

- The main difference between cold rolled and hot rolled stainless steel sheets lies in the manufacturing process and the resulting surface finish. Cold rolled stainless steel sheets are produced by rolling the steel at room temperature. This process involves passing the steel through a series of rollers to reduce its thickness and achieve the desired shape. Cold rolling results in a smoother and more refined surface finish, with less surface defects and a tighter tolerance on thickness. The cold rolling process also enhances the strength and hardness of the stainless steel sheet. On the other hand, hot rolled stainless steel sheets are manufactured by heating the steel above its recrystallization temperature and then rolling it through a series of rollers. This process is typically carried out at a higher temperature than cold rolling, which results in a rougher surface finish. Hot rolling is generally used for thicker sheets and produces a more variable thickness and hardness compared to cold rolling. In terms of applications, cold rolled stainless steel sheets are commonly used in industries that require precise measurements, such as automotive, aerospace, and construction. The smoother surface finish of cold rolled sheets makes them suitable for applications where aesthetics and surface quality are important. Hot rolled stainless steel sheets, on the other hand, are often used in applications where strength and durability are the primary requirements, such as structural components in buildings, industrial machinery, and equipment. In summary, the main differences between cold rolled and hot rolled stainless steel sheets are the manufacturing process, resulting surface finish, and their respective applications. Cold rolled sheets offer a smoother surface finish and tighter thickness tolerance, while hot rolled sheets have a rougher surface finish and are more suitable for applications requiring strength and durability.

- Q:Can stainless steel sheets be used for elevator ceilings?

- Yes, stainless steel sheets can be used for elevator ceilings. Stainless steel is a durable and visually appealing material that is often used in elevators due to its resistance to corrosion, easy maintenance, and modern aesthetic. It provides a sleek and polished look to elevator ceilings and can enhance the overall design of the elevator interior.

- Q:Can stainless steel sheets be used for swimming pool construction?

- Yes, stainless steel sheets can be used for swimming pool construction. Stainless steel is a durable and corrosion-resistant material, making it suitable for withstanding the harsh conditions of a swimming pool environment. It is commonly used for constructing pool walls, floors, and other structural components.

- Q:What are the different welding techniques used for stainless steel sheets?

- Various welding techniques are commonly employed for stainless steel sheets, each offering distinct advantages and considerations. 1. TIG Welding (Gas Tungsten Arc Welding): TIG welding, a versatile and precise method, proves suitable for thin stainless steel sheets. It involves using a non-consumable tungsten electrode to generate an electric arc that melts and fuses the metals. High-quality welds with minimal heat distortion and excellent aesthetic appearance are ensured. 2. MIG Welding (Gas Metal Arc Welding): MIG welding, known for its efficiency and user-friendliness, is a popular choice for stainless steel sheets. It employs a consumable electrode wire and an inert gas shield to protect the weld from atmospheric contamination. MIG welding exhibits faster speed than TIG welding and performs well on thicker stainless steel sheets. 3. Spot Welding: Joining two stainless steel sheets together, spot welding applies pressure and heat using electrodes. This technique finds common use in applications where a continuous seam is unnecessary, such as in automotive manufacturing or appliance production. 4. Plasma Arc Welding: Similar to TIG welding, plasma arc welding employs a more concentrated arc produced by a constricted nozzle. This technique allows for deeper penetration on stainless steel sheets, making it suitable for thicker materials or specialized applications. 5. Laser Welding: Laser welding, a precise and rapid technique, employs a high-powered laser beam to melt and join stainless steel sheets. It offers exceptional control over the welding process and proves suitable for thin to medium thickness stainless steel sheets. However, laser welding may require specialized equipment and expertise. The choice of welding technique depends on various factors, including the thickness of the stainless steel sheets, desired weld quality, production speed, and equipment availability. Each technique possesses its own advantages and limitations.

- Q:Are stainless steel sheets easy to clean?

- Yes, stainless steel sheets are easy to clean. They have a smooth surface that is resistant to stains and can be easily wiped clean with soap and water. Additionally, they are also resistant to rust and corrosion, making them low-maintenance and suitable for various applications.

- Q:What is the elongation of stainless steel sheets?

- The elongation of stainless steel sheets refers to the ability of the material to stretch or deform under tension before breaking. It is typically expressed as a percentage and represents the maximum strain the steel can undergo without fracturing.

- Q:How do stainless steel sheets differ from other types of sheets?

- Stainless steel sheets set themselves apart from other types of sheets primarily due to their composition and distinctive properties. Unlike sheets made from materials like aluminum, brass, or copper, stainless steel sheets are manufactured using an alloy of iron, chromium, and other elements. The corrosion resistance of stainless steel sheets is one of the key distinctions. By adding chromium to the alloy, a passive layer forms on the surface of the sheet, safeguarding it against rust and corrosion. As a result, stainless steel sheets are highly durable and well-suited for diverse applications, particularly in environments exposed to moisture, chemicals, or extreme temperatures. Another factor that distinguishes stainless steel sheets is their strength and toughness. They possess exceptional mechanical properties, including high tensile strength, which renders them resistant to deformation and damage. Consequently, stainless steel sheets are more dependable and long-lasting compared to other sheet types. Moreover, stainless steel sheets offer an extensive range of aesthetic possibilities. They can be easily customized with various finishes, such as brushed, polished, or embossed, to achieve different appearances and textures. This versatility in design makes stainless steel sheets a popular choice in architectural, interior design, and decorative applications. Furthermore, stainless steel sheets boast excellent hygiene properties, qualifying them for use in the food and healthcare industries. They are easy to clean, non-porous, and non-reactive, preventing the growth of bacteria and ensuring the safety and cleanliness of the surfaces they cover. In conclusion, the unique characteristics of stainless steel sheets, including their corrosion resistance, strength, durability, aesthetic options, and hygiene properties, distinguish them from other sheet types. As a result, stainless steel sheets serve as a versatile and reliable choice for a wide range of applications across various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Sheets 2B BA finish 201 304 316 430

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords