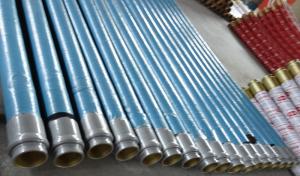

RUBBER END HOSES 3 METERS

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Name: Rubber End Hose 5’’ 3M

1. Specification

Type: 2 layers steel wire or 4 layers steel wire

working pressure: 85bar or 1232PSI

Dimensions: DN100MM, DN125MM, DN150MM, 4'', 5", 6''

Flanges: Single end, or double ends

Coupling: Painted or Galvanized.

Different Length : 3m, 4m, 5m.

Notes: total series of rubber hose for different brand concrete pump available from us, different length of rubber hose as customers requirments .

2. Application

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery and placement pumping.

Our rubber hoses for concrete pump have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package and Delivery

Every 200pcs put in one 20 feet container.

4. Production

Our Concrete Pump rubber hoses are made with advanced technology of weaving and natural rubber formula.

5. Why choose us?

1) Brand-name Parts

2) Country of Origin

3) Competitive Price

4) Good Product Performance

5) Prompt Delivery

6) Quality Approvals

7) Good Reputation

8) Expedite Communication

9) Good Packaging

10) Distributorships Offered

11) One Step Service

12) Good Quality Service

13) Small Orders Accepted

14) Overseas Service Branches

- Q:What are the functions of concrete pump truck?

- It is composed of pump body and conveying pipe. It is divided into piston type, extrusion type and water pressure diaphragm type according to the structure. The pump body is mounted on the automobile chassis, and then equipped with telescopic or bent cloth rods to form a pump truck

- Q:How do I properly maintain and replace concrete delivery pipes in concrete pump spare parts?

- Properly maintaining and replacing concrete delivery pipes in concrete pump spare parts is crucial to ensure the efficient and safe operation of the concrete pump. Here are some steps you can follow: 1. Regular Inspection: Regularly inspect the concrete delivery pipes for any signs of wear and tear, cracks, or damage. Look for any leaks or blockages that may affect the concrete flow. Identify any weak points that may require replacement. 2. Cleaning: Clean the concrete delivery pipes thoroughly after each use. Use water and a high-pressure hose to remove any concrete residue or build-up. This will prevent clogging and maintain the smooth flow of concrete. 3. Lubrication: Apply a suitable lubricant to the inner surface of the pipes to reduce friction and prevent concrete from sticking. This will help prolong the life of the pipes and ensure smooth concrete flow. 4. Replace Worn-out Parts: Monitor the condition of the delivery pipes and replace any worn-out or damaged parts promptly. Over time, the pipes may become corroded or develop cracks, affecting their performance. Replace these parts with high-quality spare parts to ensure the best results. 5. Proper Handling: Handle the concrete delivery pipes with care to avoid any unnecessary damage. Avoid dropping or mishandling the pipes during transportation or storage. Protect them from extreme weather conditions and store them in a dry and secure place. 6. Training and Safety: Ensure that the personnel operating the concrete pump are well-trained in handling and maintaining the equipment. Educate them about the importance of regular inspections, cleaning, and replacement of parts. Emphasize safety protocols to prevent accidents and ensure the longevity of the concrete delivery pipes. By following these steps, you can properly maintain and replace concrete delivery pipes in concrete pump spare parts, ensuring the efficient and safe operation of your concrete pump. Regular maintenance and prompt replacement of worn-out parts will help extend the life of the pipes and ensure the smooth flow of concrete during construction projects.

- Q:What are the indications of a faulty concrete pump hydraulic motor?

- Some indications of a faulty concrete pump hydraulic motor may include decreased pumping efficiency, irregular or inconsistent flow of concrete, unusual noises or vibrations, leaks or drips in the hydraulic system, excessive heat in the motor, or difficulty in starting or stopping the motor.

- Q:What is the purpose of a concrete pump electric motor?

- The purpose of a concrete pump electric motor is to provide the necessary power and torque to pump concrete from one location to another, eliminating the need for manual labor and increasing efficiency in construction projects.

- Q:Can concrete pump spare parts be pre-assembled or pre-tested before installation?

- Yes, concrete pump spare parts can be pre-assembled or pre-tested before installation. Pre-assembling the spare parts allows for quality control measures to be taken before the actual installation process. This ensures that any defects or issues with the parts can be identified and rectified before they are installed in the concrete pump. Additionally, pre-testing the spare parts helps to ensure their functionality and compatibility with the pump system. It allows for any necessary adjustments or modifications to be made beforehand, reducing the risk of complications during the actual installation process. Overall, pre-assembling and pre-testing concrete pump spare parts is a common practice to ensure the smooth and efficient operation of the pump system.

- Q:How can a faulty filter affect the pumping process?

- A faulty filter can impede the pumping process by allowing debris, contaminants, or particles to pass through and clog or damage the pump components. This can result in reduced efficiency, increased wear and tear, decreased flow rates, and potential pump failure.

- Q:How often should hydraulic pumps be inspected or replaced in a concrete pump?

- Hydraulic pumps in a concrete pump should be inspected regularly to ensure their proper functioning and prevent any potential issues. The frequency of inspections depends on various factors such as the intensity of use, operating conditions, and manufacturer's recommendations. Generally, it is recommended to inspect hydraulic pumps in a concrete pump every 500 to 1,000 operating hours or at least once a year, whichever comes first. However, if the pump is being used in harsh or demanding conditions, more frequent inspections may be necessary. Replacement of hydraulic pumps should be based on their condition and the recommendations of the manufacturer. If the pump shows signs of significant wear and tear, leaks, reduced performance, or any other issues that cannot be resolved through maintenance or repair, it may be necessary to replace the hydraulic pump to ensure the safe and efficient operation of the concrete pump.

- Q:In general, how much concrete will be transported per hour for the concrete pump and the pump?

- Tank car replacement, reversing the car by about 5-8 minutes

- Q:What are the types, classifications and specifications of concrete pump?

- According to the maximum hourly transport rate, there are 20-100m3 range, and most of the concrete pump can achieve two variable displacement or stepless variable

- Q:What are the different types of concrete pump hopper agitator blades?

- In the construction industry, there exists a variety of concrete pump hopper agitator blades. These blades have different designs and functions, all aimed at efficiently mixing and agitating the concrete mixture in the hopper. By achieving a consistent and homogeneous mixture, the concrete can be pumped onto the project site effectively. 1. Paddle Blades: The most commonly used agitator blades in concrete pump hoppers are paddle blades. These blades have a flat, paddle-like design that effectively mixes the concrete ingredients. They are typically made of high-quality steel or hardened rubber to ensure durability and optimal performance. 2. Helical Blades: Another type of agitator blade is the helical blade, which has a spiral shape. This design creates a gentle, swirling motion within the hopper, preventing the formation of lumps and ensuring a smooth and well-mixed concrete mixture. 3. Ribbon Blades: Thin and flat, ribbon blades resemble ribbons and are placed vertically in the hopper. They rotate along their axis to thoroughly mix the concrete ingredients. Ribbon blades are known for their ability to prevent clogging and improve the efficiency of concrete pumping. 4. Fan Blades: With a unique fan-shaped design, fan blades create a powerful airflow within the hopper to agitate the concrete mixture. This type of blade is particularly effective in preventing the segregation of concrete ingredients and maintaining a consistent mixture. 5. Tine Blades: Tine blades feature multiple prongs or tines extending from a central hub. They provide a more aggressive agitation action, making them suitable for mixing heavier concrete mixes or those containing large aggregates. The selection of agitator blades depends on various factors, such as the type of concrete, desired consistency, and specific project requirements. It is crucial to choose the appropriate blade type and perform regular maintenance to optimize the performance and lifespan of the concrete pump hopper agitator.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

RUBBER END HOSES 3 METERS

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords