Hot Rolled Steel Plate SS400 Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

GRADE:

SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD:

GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC:

1) Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2) Thickness:1.5mm-200mm or as customers’ special requirements

3) Length: 2-12m or as customers’ special requirements

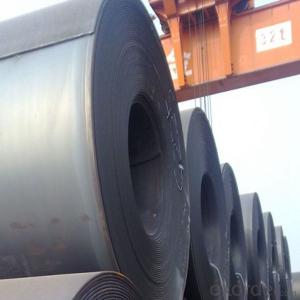

DETAILED PICTURES FOR STEEL COILS

PACKAGING &DELIVERY FOR STEEL COILS/SHEETS

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q:Are the steel sheets resistant to impact or denting?

- Yes, steel sheets are highly resistant to impact and denting. Steel is known for its exceptional strength and durability, making it one of the most reliable materials for various applications. The inherent properties of steel, such as its high tensile strength and toughness, provide excellent resistance against impact and denting. Additionally, steel sheets can be further enhanced with special coatings or treatments to increase their resistance to impacts or dents, making them even more reliable in demanding environments. Overall, steel sheets are a preferred choice for applications where impact resistance and denting are significant concerns.

- Q:What are the safety considerations when working with steel sheets?

- When working with steel sheets, there are several important safety considerations to keep in mind: 1. Personal Protective Equipment (PPE): It is crucial to wear appropriate PPE to protect yourself from potential hazards. This may include safety glasses or goggles, gloves, steel-toed boots, and a hard hat. 2. Lifting and handling: Steel sheets can be heavy and awkward to handle. Use proper lifting techniques, such as bending your knees and keeping your back straight, or use mechanical lifting equipment like cranes or forklifts. Never attempt to lift a sheet that is too heavy for you alone. 3. Slips, trips, and falls: Steel sheets can create slippery surfaces, especially when wet or oily. Keep work areas clean and free of debris, and use non-slip mats or flooring where appropriate. Be cautious of trip hazards, such as cords or tools, and use caution when moving around the work area. 4. Sharp edges and corners: Steel sheets often have sharp edges and corners that can cause cuts or injuries. Use caution when handling and moving them, and wear gloves to protect your hands. If necessary, use edge protectors or file down any sharp edges to reduce the risk of injuries. 5. Fire hazards: Steel sheets can be flammable when exposed to high temperatures or sparks. Ensure that work areas are clear of flammable materials and follow proper fire safety procedures, such as having fire extinguishers readily available and knowing how to use them. 6. Noise and vibration: Working with steel sheets can generate significant noise and vibration. Wear ear protection, such as earplugs or earmuffs, to protect your hearing. If using power tools, ensure they are properly maintained and have vibration-dampening features to minimize the risk of hand-arm vibration syndrome. 7. Adequate ventilation: Some steel sheets may release fumes or dust when cut or welded. Ensure that the workspace is well-ventilated to prevent the accumulation of harmful gases or particles. If necessary, use exhaust fans or wear respiratory protection to avoid inhalation of hazardous substances. By following these safety considerations, you can minimize the risks associated with working with steel sheets and create a safer work environment for yourself and others.

- Q:What is the minimum thickness of a steel sheet?

- The minimum thickness of a steel sheet depends on various factors, including the specific grade of steel being used, the intended application, and the manufacturing process. However, in general, steel sheets can be produced with thicknesses ranging from as thin as 0.4 millimeters (0.016 inches) to several millimeters thick. It is important to note that thinner steel sheets are typically used for applications that require flexibility and lightness, such as automotive body panels or electrical enclosures, while thicker sheets are employed for structural purposes, such as construction materials or heavy machinery components. Ultimately, the minimum thickness of a steel sheet is determined by the specific requirements of the project or application.

- Q:Can steel sheets be used for construction formwork or molds?

- Yes, steel sheets can be used for construction formwork or molds, although they may not be as commonly used as other materials such as plywood or timber. Steel sheets are durable, strong, and can provide a smooth and even surface for casting concrete. They are particularly suitable for large-scale construction projects where formwork needs to withstand high pressures and loads. Steel sheets can be custom-designed and fabricated to meet specific project requirements, offering flexibility in shape, size, and configuration. However, it is important to consider the cost, weight, and availability of steel sheets compared to other formwork materials before making a decision.

- Q:Are steel sheets resistant to extreme temperatures?

- Yes, steel sheets are generally resistant to extreme temperatures.

- Q:Are the steel sheets suitable for automotive applications?

- Yes, steel sheets are highly suitable for automotive applications. Steel is widely used in the automotive industry due to its exceptional strength, durability, and versatility. It offers excellent crash resistance, making it ideal for vehicle structures to ensure passenger safety. Additionally, steel sheets can be easily formed into complex shapes, allowing for the production of various automotive components such as body panels, chassis, and frames. Steel also provides good corrosion resistance, which is crucial for withstanding harsh environmental conditions. Moreover, it is cost-effective and readily available, making it a popular choice for automakers. Overall, steel sheets are a reliable and suitable material for automotive applications.

- Q:What are the different types of steel alloys used for sheets?

- There are several types of steel alloys commonly used for sheets, including carbon steel, stainless steel, galvanized steel, and alloy steel. Carbon steel is a versatile and widely-used alloy that offers good strength and durability. Stainless steel is highly resistant to corrosion and is often used in applications where hygiene and aesthetics are important. Galvanized steel is coated with a layer of zinc to protect against rusting and is commonly used in outdoor and industrial applications. Alloy steel is a combination of different elements to enhance specific properties such as strength, toughness, and heat resistance.

- Q:What are the different types of surface finishes available for steel sheets?

- Some different types of surface finishes available for steel sheets include hot rolled, cold rolled, galvanized, and coated finishes.

- Q:What is a die steel plate?

- Pressure plate template is made of galvanized steel sheet or the antiseptic treatment, the machine rolled into a groove plate with a cross section of the ladder waveform or project template material open box steel shell.

- Q:What is the difference between a HRPO and HRSPO steel sheet?

- The main difference between a HRPO (Hot Rolled Pickled and Oiled) and HRSPO (Hot Rolled Skin Pass) steel sheet lies in the manufacturing process and the resulting properties of the two types of sheets. HRPO steel sheets are produced by hot rolling a steel slab and then subjecting it to a pickling process where the surface scale is removed using an acid bath. After pickling, the steel sheet is then oiled to provide a protective coating. The pickling process imparts a clean, smooth surface to the sheet, while the oiling helps prevent corrosion and improve formability. HRPO sheets are typically used in applications that require good surface finish and paintability. On the other hand, HRSPO steel sheets undergo an additional skin pass rolling process after pickling and oiling. This process involves passing the sheet through a set of rolls to further improve its surface quality, resulting in a smoother and more uniform surface finish compared to HRPO sheets. The skin pass process also imparts better flatness and dimensional accuracy to the sheet. HRSPO sheets are commonly used in applications that demand higher surface quality, such as automotive panels, appliances, and electrical enclosures. In summary, while both HRPO and HRSPO steel sheets are pickled and oiled, the additional skin pass rolling step in the manufacturing process of HRSPO sheets enhances their surface quality, flatness, and dimensional accuracy, making them suitable for more demanding applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Plate SS400 Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords