Fiberglass Geogrids with High Tensile Strength Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification---Fiberglass Geogrid

Introduction:

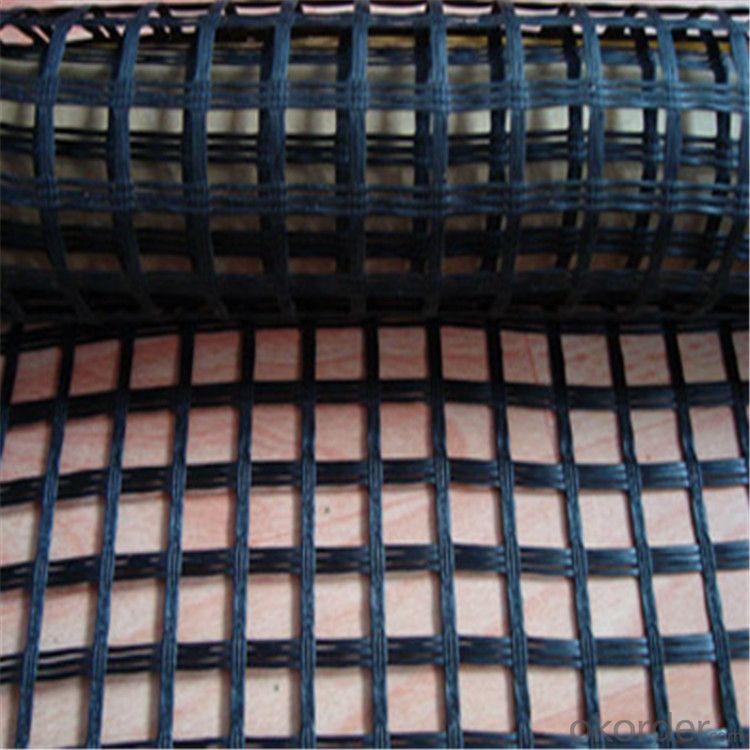

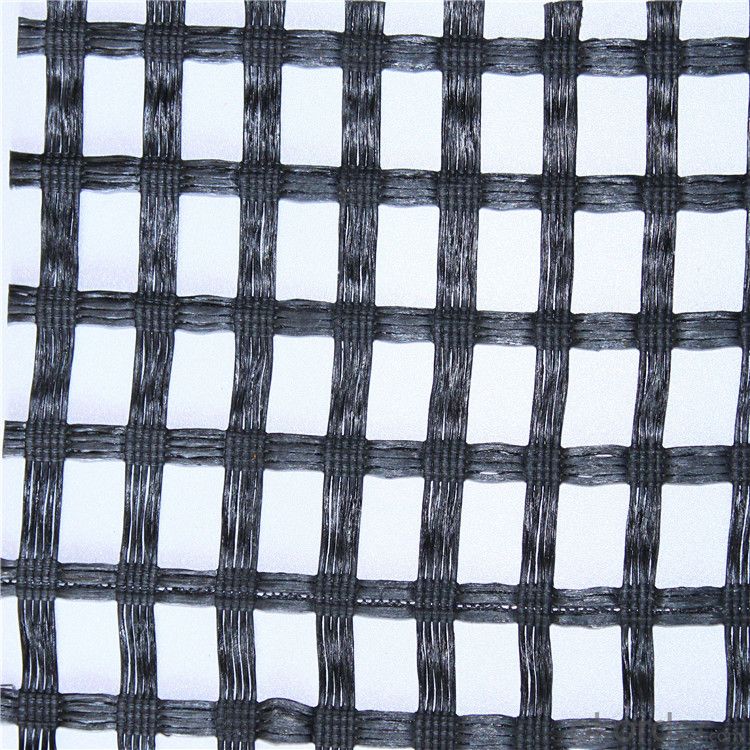

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Features:

1. High tensile strength in warp and across directions

2. Low Elongation

3. High flexibility

4. High and low temperature resistance

Application:

This product is used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, roadbed, and softland loading capacity strengthen.

Function:

This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile

strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after

surface covering own the favorable property of alkali resistance and aging resistance.

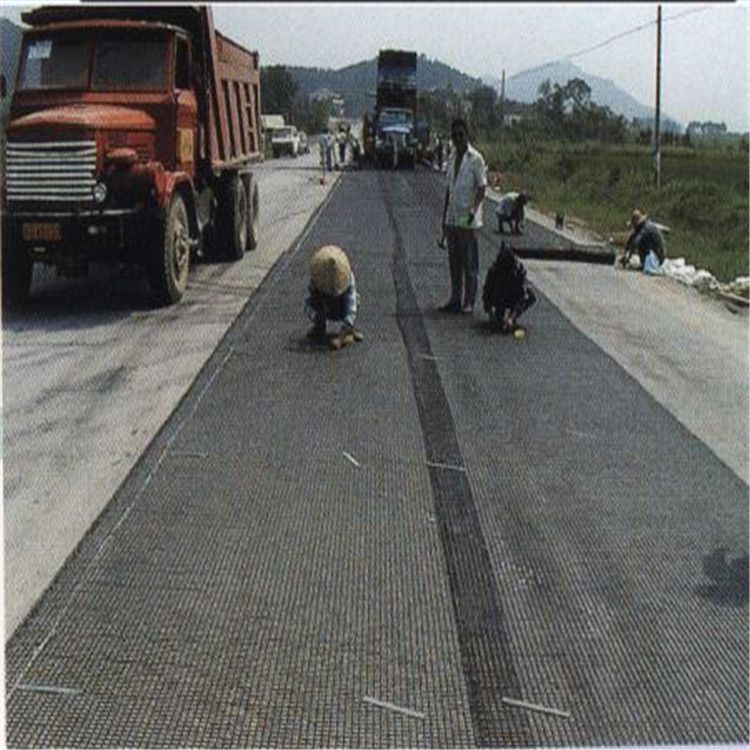

It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces).

Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road

crackle.

This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the

roadbed 。

Properties of Fiberglass Geogrid

Specification | EGA30-30 | EGA50-50 | EGA80-80 | EGA100-100 | EGA120-120 | |

Mesh size(mm) | 25.4×25.4 Or 12.5×12.5 | |||||

Breaking strength ≥(KN/m) | Warp direction | 30 | 50 | 80 | 100 | 120 |

Across warp | 30 | 50 | 80 | 100 | 120 | |

Elongation at break ≤(%) | Warp direction | 3 | ||||

Across warp | 3 | |||||

Elasticity modulus(GPA) | 67 | |||||

Thermal tolerance | -100~280℃ | |||||

Width | 1~6m | |||||

Image of Fiberglass Geogrid

- Q:What are the applications of geogrids in civil engineering?

- Geogrids are extensively used in civil engineering for various applications such as soil stabilization, slope reinforcement, retaining wall construction, and pavement reinforcement. They provide strength and stability to soil structures, prevent erosion, increase load-bearing capacity, and enhance overall structural integrity. Geogrids are also employed in infrastructure projects like road construction, railway tracks, landfill sites, and coastal protection, contributing to the longevity and durability of these civil engineering projects.

- Q:Can geogrids be used in reinforcement of concrete pavements?

- Yes, geogrids can be used in the reinforcement of concrete pavements. Geogrids are often used as a cost-effective solution to enhance the strength and durability of concrete pavements. They help to distribute the load more evenly, reducing cracking and improving the overall performance and lifespan of the pavement.

- Q:Can geogrids be used in reinforcement of coastal structures?

- Yes, geogrids can be used in the reinforcement of coastal structures. Geogrids are commonly used in coastal engineering to enhance the stability and strength of structures such as seawalls, revetments, and breakwaters. They provide additional reinforcement by improving soil cohesion and preventing erosion, thus increasing the durability and resilience of coastal structures against wave action and other environmental forces.

- Q:How do geogrids help in reducing the risk of soil erosion?

- Geogrids help in reducing the risk of soil erosion by providing reinforcement and stabilization to the soil. They are typically made of high-strength materials like polyester or polypropylene, which are resistant to degradation and can withstand heavy loads. When placed in soil, geogrids create a network of interconnected cells that increase the soil's resistance to erosion caused by water flow or wind. This reinforcement prevents the soil particles from being displaced, maintaining the integrity of the slope or embankment. Geogrids also improve soil drainage, allowing excess water to pass through and reducing the likelihood of erosion. Overall, geogrids act as a physical barrier against erosion forces, enhancing the stability and longevity of soil structures.

- Q:Plastic grid plate making process

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material

- Q:How do geogrids prevent differential settlement?

- Geogrids prevent differential settlement by distributing the load and enhancing the stability of soil by providing reinforcement. They improve the overall strength and stiffness of the soil, reducing the likelihood of differential settlement occurring.

- Q:Can geogrids be used in reinforcement of rail embankments and cuttings?

- Yes, geogrids can be used in the reinforcement of rail embankments and cuttings. Geogrids are commonly used in civil engineering projects to enhance the stability and strength of soil structures. By placing geogrids within the embankments or cuttings, they help distribute the load more evenly and reduce the likelihood of slope failures or ground movement. This reinforcement technique improves the overall durability and longevity of rail infrastructure.

- Q:Do geogrids provide reinforcement to geosynthetic clay liners in waste containment facilities?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners in waste containment facilities. Geogrids are typically used to enhance the stability and strength of geosynthetic clay liners, improving their ability to withstand lateral forces and prevent soil erosion.

- Q:How are geogrids installed in the field?

- Geogrids are typically installed in the field by first preparing the soil surface and removing any debris or vegetation. The geogrid is then rolled out and placed on top of the prepared soil. It is important to ensure that the geogrid is properly aligned and overlapping if multiple rolls are being used. The edges of the geogrid are then securely anchored using stakes or pins to prevent movement during installation. Finally, the soil is backfilled and compacted over the geogrid to provide additional support and load distribution.

- Q:Can geogrids be used in retaining walls for residential applications?

- Yes, geogrids can be used in retaining walls for residential applications. Geogrids are commonly used to reinforce and stabilize retaining walls, providing additional strength and stability to the structure. They help prevent soil erosion, improve drainage, and increase the overall durability of the retaining wall.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrids with High Tensile Strength Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords