Fiberglass Geogrids for Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance

Fiberglass Geogrid Features :

1. Fiberglass geogrid for soil reinforcement

2. Pavement subgrade stabilization

3. Area /Ground stabilization

4. Pavement base reinforcement

5. Working & load transfer platforms

6. Rail Track-bed stabilization

7. Reinforced granular foundation beds

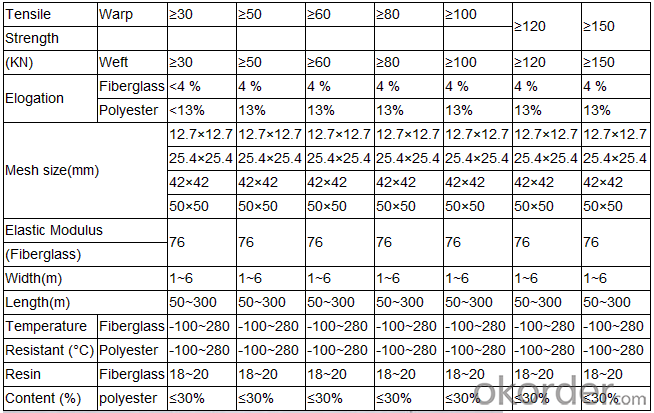

Fiberglass Geogrid Specification:

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:What is the minimum net size of geogrid mesh Center

- The grid dimensions of the different materials are different, because the glass fiber and polyester is prepared, so the smallest mesh size, plastic medium, the largest steel and PP welding.

- Q:How do geogrids enhance the performance of mechanically stabilized earth walls?

- Geogrids enhance the performance of mechanically stabilized earth walls by providing tensile strength and reinforcing the soil structure. They distribute lateral forces and soil loads more evenly, reducing the potential for wall failure or deformation. Additionally, geogrids improve the overall stability and durability of the wall by increasing its resistance to settlement, slope erosion, and seismic activity.

- Q:How much cheaper than steel reinforced plastic geogrid

- Specifications of different prices, the general specification of 4 to 6.5 square.

- Q:Can geogrids be used in geotechnical engineering?

- Yes, geogrids can be used in geotechnical engineering. They are often used as reinforcement materials in soil structures to improve their strength, stability, and load-bearing capacity. Geogrids are particularly effective in applications such as retaining walls, embankments, slopes, and pavements. They provide reinforcement to the soil, preventing lateral spreading, reducing settlement, and increasing overall performance of the geotechnical structures.

- Q:How do geogrids help in reducing the risk of landslides?

- Geogrids help in reducing the risk of landslides by reinforcing the soil and increasing its stability. They are typically placed in the ground to provide additional strength and prevent soil movement, effectively distributing the forces acting on the slope. This reinforcement helps to resist the gravitational pull that can cause landslides, reducing the likelihood of slope failure and subsequent damage.

- Q:Can geogrids be used in reinforced concrete structures?

- Yes, geogrids can be used in reinforced concrete structures. Geogrids are commonly used as a reinforcing material in concrete structures to enhance their load-bearing capacity and reduce cracking. They provide additional tensile strength and help distribute the applied loads more efficiently, improving the overall structural performance.

- Q:Are geogrids effective in preventing soil erosion on hillsides?

- Yes, geogrids are effective in preventing soil erosion on hillsides.

- Q:What are the differences between geogrids and geosynthetic clay liners?

- Geogrids and geosynthetic clay liners (GCLs) are both geosynthetic materials used in geotechnical applications, but they have distinct differences. Geogrids are typically made from high-strength polymers, such as polypropylene or polyester, and have a grid-like structure. They are used to reinforce soil, providing tensile strength and preventing soil erosion. Geogrids are commonly used in road construction, retaining walls, and slope stabilization projects. On the other hand, geosynthetic clay liners (GCLs) consist of a layer of bentonite clay sandwiched between two geotextiles. The clay component of GCLs gives them excellent hydraulic barrier properties, making them highly effective in containment applications. GCLs are commonly used in landfills, mining sites, and other projects that require the containment of liquids or gases. In summary, while geogrids reinforce soil and provide tensile strength, geosynthetic clay liners act as hydraulic barriers and are used for containment purposes.

- Q:Geogrid and geotextile, the role is the same?

- The main function of geotextile is to isolate the protective function of drainage and reinforcement,

- Q:How to determine the number of geogrid detection method

- 2) according to the design of the location, along the road to the laying of the grid, laying the grille, should pay attention to the connection between the grid and straightening smooth. Grille of the longitudinal and transverse joints can use nylon or polyester rope sewn or U nail connection method between the grid as a whole, grid overlapping width not less than 20cm, in the direction of the stress intensity of the joint shall not be less than the design tensile strength of materials. The grid distortion, fold, overlap, is not conducive to play its role, thus laying by hands straightened, the grid is smooth and uniform, geogrid every 1.5-2.0m paved with hook nail fixed on the ground.3) fill: after the completion of the grille, should be timely (48 hours) filling. Each layer should be carried out according to the principle of "the first two sides, the middle of the back". The packing is not allowed to be unloaded directly on the geogrid. It must be unloaded on the soil surface which has been paved. The soil unloading height is not more than 1m. All vehicles and construction machinery shall not be allowed to walk directly on the paved geogrid, but only to be allowed to travel along the axis of the embankment.4) the upper and lower sides of the geogrid, and 8 cm from the grid layer shall not be more than 6 cm in diameter.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrids for Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords