Fiberglass FRP Phenolic Molded and Pultruded Grating with Good Shape

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

- Electrical Insulating

Aging Resistance

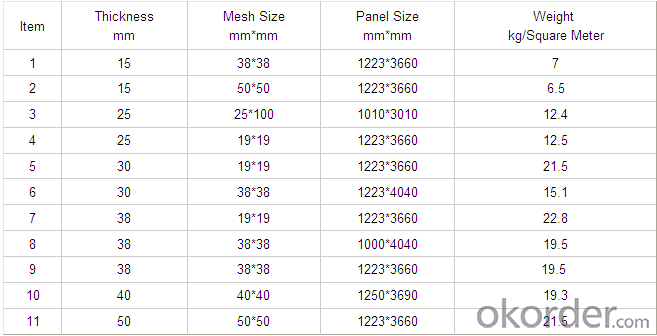

Specification

Advantage

coated with prevent aging layer

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

- Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

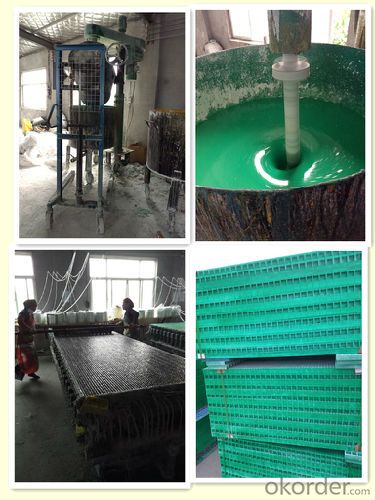

PROCESS

FACTORY

- Q:What are the insulation properties of FRP pultrusion profiles?

- FRP pultrusion profiles have excellent insulation properties due to the nature of the materials used in their composition. FRP, which stands for Fiber Reinforced Polymer, combines the strength of the fiber reinforcement with the insulating properties of the polymer matrix. The insulation properties of FRP pultrusion profiles are primarily determined by the polymer matrix, which is typically made of thermosetting resins such as polyester, vinyl ester, or epoxy. These resins have low thermal conductivity, meaning they are poor conductors of heat. This property allows FRP pultrusion profiles to effectively reduce heat transfer through conduction. In addition to low thermal conductivity, FRP pultrusion profiles also exhibit excellent electrical insulation properties. The polymer matrix acts as an insulator, preventing the flow of electric current and reducing the risk of electrical accidents or damage to equipment. Furthermore, FRP pultrusion profiles are also resistant to moisture, chemicals, and UV radiation, which further enhances their insulation properties. Moisture and chemicals can degrade the insulation properties of materials, but FRP is highly resistant to these factors, ensuring long-term insulation performance. Overall, FRP pultrusion profiles offer superior insulation properties, making them an ideal choice for applications where thermal or electrical insulation is required. They provide a reliable and durable solution for various industries, including construction, electrical, and transportation.

- Q:How do FRP pultrusion profiles handle compression loads?

- FRP (Fiber-Reinforced Polymer) pultrusion profiles handle compression loads in a unique and effective way due to their structure and material composition. Pultruded profiles are made by pulling continuous fibers, such as glass or carbon, through a resin bath and then through a heated die, where the resin is cured and the shape is formed. When it comes to compression loads, FRP pultrusion profiles exhibit excellent performance. The continuous fibers embedded within the resin matrix make the profiles highly stiff and strong, allowing them to effectively resist compressive forces. The fibers distribute the load evenly along the length of the profile, preventing localized failure and ensuring overall structural integrity. The fiber reinforcement in FRP pultrusion profiles also provides excellent resistance against buckling. Buckling is a phenomenon where a slender structural member fails due to excessive compressive loads causing instability. The high strength-to-weight ratio of the fibers helps prevent buckling and allows the profiles to withstand substantial compression forces without compromising their structural integrity. Additionally, the resin matrix in FRP pultrusion profiles plays a crucial role in handling compression loads. The resin provides a protective layer around the fibers, preventing them from being damaged or fractured under compressive forces. It also acts as a load transfer medium, distributing the compressive load to the fibers, which then carry the load throughout the entire profile. Overall, FRP pultrusion profiles are well-suited for handling compression loads due to their fiber reinforcement and resin matrix. They offer high strength, stiffness, and resistance to buckling, making them an ideal choice for a wide range of applications where compression loads are a concern.

- Q:Are FRP pultrusion profiles resistant to hail or impact damage?

- Yes, FRP pultrusion profiles are typically resistant to hail or impact damage due to their strong and durable composition. The combination of reinforced fibers and resin matrix make them highly resistant to external forces, ensuring longevity and minimal damage in the event of hail or impact.

- Q:Are FRP pultrusion profiles resistant to electromagnetic interference?

- Yes, FRP pultrusion profiles are generally resistant to electromagnetic interference. The non-conductive nature of the fiberglass reinforced polymer (FRP) material provides insulation against electromagnetic fields, making them less susceptible to interference. However, the specific level of resistance may depend on the design and composition of the FRP profiles.

- Q:How do FRP pultrusion profiles perform in extreme humidity conditions?

- FRP pultrusion profiles perform exceptionally well in extreme humidity conditions. The fiberglass-reinforced plastic material used in the profiles is highly resistant to moisture absorption, preventing any degradation or dimensional changes. This makes them ideal for applications in humid environments, as they maintain their strength, durability, and structural integrity over time.

- Q:Can FRP pultrusion profiles be used in the construction of theme park rides?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of theme park rides. FRP pultrusion profiles offer several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for constructing ride structures that need to withstand dynamic loads and forces. Their high strength-to-weight ratio allows for the creation of large, complex structures that can support the weight of riders and withstand the forces generated during operation. Additionally, FRP pultrusion profiles are corrosion-resistant, which is crucial for theme park rides that are often exposed to outdoor environments, including moisture, chemicals, and UV radiation. This corrosion resistance ensures that the ride structures remain durable and safe over their lifespan, reducing the need for costly maintenance and repairs. Another advantage of FRP pultrusion profiles is their design flexibility. They can be easily molded into various shapes and sizes to meet the specific requirements of theme park ride designs. This versatility allows for the creation of unique and visually appealing ride structures that enhance the overall experience for park visitors. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties, which can be essential for rides that involve electrical components or systems. This insulation helps to minimize the risk of electrical hazards and ensures the safety of riders and operators. In conclusion, FRP pultrusion profiles are well-suited for the construction of theme park rides due to their lightweight, high strength, corrosion resistance, design flexibility, and electrical insulation properties. These profiles can contribute to the development of safe, durable, and visually appealing ride structures that enhance the enjoyment and excitement of theme park visitors.

- Q:How do FRP pultrusion profiles perform in extreme heat temperatures?

- FRP pultrusion profiles are renowned for their exceptional performance in extreme heat conditions. The profiles acquire remarkable heat resistance properties due to the distinct combination of materials utilized in the pultrusion process, such as fiberglass reinforcement and thermosetting resin matrix. One of the primary benefits of FRP pultrusion profiles lies in their capacity to uphold dimensional stability even when subjected to elevated temperatures. Unlike conventional materials like steel or aluminum, which may expand or deform under extreme heat, FRP profiles retain their shape and structural integrity. Consequently, they offer a high level of reliability in applications where temperature fluctuations are frequent or where exposure to intense heat is prevalent. Furthermore, FRP pultrusion profiles possess exceptional thermal insulation properties. They possess a low thermal conductivity, effectively impeding heat transfer. This characteristic proves advantageous in situations where heat control or isolation is necessary, preventing the profiles from becoming excessively hot. Moreover, FRP pultrusion profiles boast a high heat distortion temperature (HDT). HDT refers to the temperature at which a material begins to deform under a specific load. Typically, the HDT of FRP profiles surpasses that of other materials, enabling them to endure extreme heat without compromising their structural integrity. In conclusion, FRP pultrusion profiles are highly suitable for use in extreme heat conditions. Their ability to maintain dimensional stability, resist heat transfer, and withstand high temperatures renders them a dependable choice for diverse industries, including aerospace, automotive, and infrastructure.

- Q:Can FRP pultrusion profiles be used in the construction of pedestrian tunnels?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of pedestrian tunnels. FRP profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for tunnel construction. Additionally, FRP profiles can be easily customized to meet specific design requirements and offer long-term cost savings due to their low maintenance needs.

- Q:Can FRP pultrusion profiles be used in the aerospace industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the aerospace industry. FRP materials offer several advantages that make them suitable for aerospace applications. Firstly, FRP profiles have high strength-to-weight ratios, which is crucial in the aerospace industry where weight reduction is a priority. Their lightweight nature allows for fuel efficiency and increased payload capacity. Secondly, FRP pultrusion profiles have excellent corrosion resistance, making them ideal for aerospace applications where exposure to harsh environments is common, such as high altitude, extreme temperatures, and moisture. This resistance to corrosion ensures the durability and longevity of the components, reducing maintenance and replacement costs. Additionally, FRP materials can be tailored to meet specific design requirements, enabling engineers to create complex shapes and structures with ease. This flexibility in design allows for enhanced performance and functionality in aerospace applications. Moreover, FRP pultrusion profiles exhibit excellent fatigue resistance, meaning they can withstand the cyclic loading and stress cycles that are common in aerospace operations. This characteristic ensures the reliability and safety of the components, which is of utmost importance in the aerospace industry. Furthermore, FRP materials offer electrical insulation properties, which can be advantageous in aerospace applications where electrical conductivity needs to be minimized or controlled. This insulation capability contributes to the overall safety and functionality of the components. In conclusion, FRP pultrusion profiles can indeed be used in the aerospace industry due to their high strength-to-weight ratios, corrosion resistance, flexibility in design, fatigue resistance, and electrical insulation properties. These qualities make FRP a viable and attractive choice for various aerospace applications, including aircraft structures, interior components, radomes, and others.

- Q:Can FRP pultrusion profiles be used in renewable energy projects?

- Certainly, FRP pultrusion profiles are capable of being used in renewable energy projects. They possess a wide range of advantages that make them suitable for various applications within the renewable energy sector. To begin with, FRP pultrusion profiles are both lightweight and strong, which makes them ideal for utilization in wind turbine blades. The lightweight nature of FRP materials allows for increased efficiency in wind energy generation by reducing the load on the turbine, thus enhancing overall performance. Furthermore, the high strength-to-weight ratio of FRP profiles ensures durability and longevity, even in severe environmental conditions. Additionally, FRP pultrusion profiles display exceptional resistance to corrosion, which renders them suitable for employment in solar panel mounting structures and other components exposed to moisture and outdoor elements. This corrosion resistance ensures that FRP profiles maintain their structural integrity and performance over an extended period, diminishing the need for frequent maintenance and replacement. Furthermore, FRP pultrusion profiles can be customized to meet specific project requirements, providing flexibility in design and functionality. They can be easily molded into complex shapes and sizes, facilitating the creation of innovative and efficient solutions for renewable energy projects. Moreover, FRP materials are non-conductive and possess excellent electrical insulation properties, making them suitable for use in electrical enclosures and support structures for renewable energy systems such as solar power plants. In conclusion, FRP pultrusion profiles can be effectively utilized in renewable energy projects due to their lightweight, strong, corrosion-resistant, customizable, and electrically-insulating properties. These characteristics make FRP profiles a reliable and sustainable choice for various applications within the renewable energy sector.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass FRP Phenolic Molded and Pultruded Grating with Good Shape

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords