China Polycrystalline Solar Cells With High Quality and Stable Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 PCS

- Supply Capability:

- 8000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

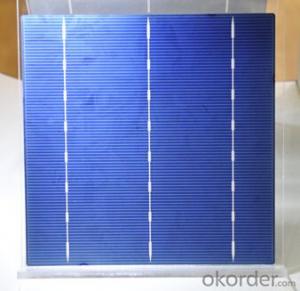

Polycrystalline Silicon Solar Cells:

Solar cells is made by solar wafer, it has three categories of solar cell right now, monocrystalline polycrystalline and thin film,These cells are entirely based around the concept of ap-n junction, which is the critical part of solar module, it is the part that can convert the light energy into electricity, the thickness is from 180um to 200um, with even busbars to conduct electricity, textured cell can decrease diffuse reflection; they are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current;With high quality and stable quality. Our Cells can greatly improve the performance of Solar Modules.

Polycrystalline Silicon Solar Cells Advantage:

• High efficiency and stable performance in photovoltaic conversion.

• Advanced diffusion technique ensuring the homogeneity of energy conversion efficiency of the cell.

• Advanced PECVD film forming, providing a dark blue silicon nitride anti-reflection film of homogenous color and attractive appearance.

• High quality metal paste for back surface and electrode, ensuring good conductivity, high pulling strength and ease of soldering.

• High precision patterning using screen printing, ensuring accurate busbar location for ease with automatic soldering a laser cutting.

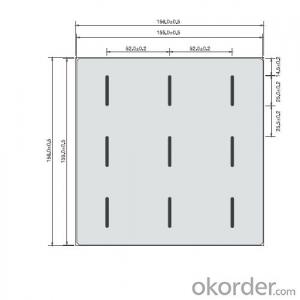

Specification:

Mechanical data and design |

Format - 156 mm × 156 mm ± 0.5 mm |

Thickness- - 200 μm ± 20 μm |

Front (-) - 1.4 mm bus bars (silver),blue anti-reflection coating (silicon nitride) |

Back (+) - 2 mm wide soldering pads (silver) back surface field (aluminium) |

Temperature Coefficient of Cells |

Voc. Temp .coef.%/K -0.364%/K |

Isc . Temp .coef.%/K +0.077%/K |

Pm. Temp. coef.%/K -0.368%/K |

Electrical Characteristic |

Efficiency (%) Pmpp (W) Umpp (V) Impp (A) Voc (V) Isc (A) |

18.00% 4.380 0.538 8.141 0.634 8.740 |

17.90% 4.356 0.538 8.097 0.634 8.725 |

17.80% 4.331 0.537 8.065 0.633 8.710 |

17.70% 4.307 0.536 8.035 0.632 8.695 |

17.60% 4.283 0.535 8.006 0.631 8.680 |

17.50% 4.258 0.534 7.974 0.630 8.665 |

17.40% 4.234 0.533 7.944 0.629 8.650 |

17.30% 4.210 0.532 7.914 0.628 8.635 |

17.20% 4.185 0.531 7.88 -- 0.627 -- 8.620 |

17.10% 4.161 0.530 7.851 0.626 8.605 |

17.00% 4.137 0.529 7.820 0.625 8.590 |

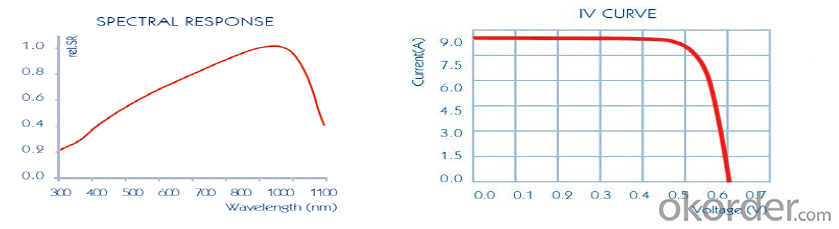

Intensity Dependence |

Intensity [W/m2] Isc× [mA] Voc× [mV] Pmpp |

1000 1.00 1.000 1.00 |

900 0.90 1.000 0.90 |

800 0.80 0.99 0.80 |

500 0.50 0.96 0.49 |

300 0.30 0.93 0.29 |

200 0.20 0.92 0.19 |

IV Curve

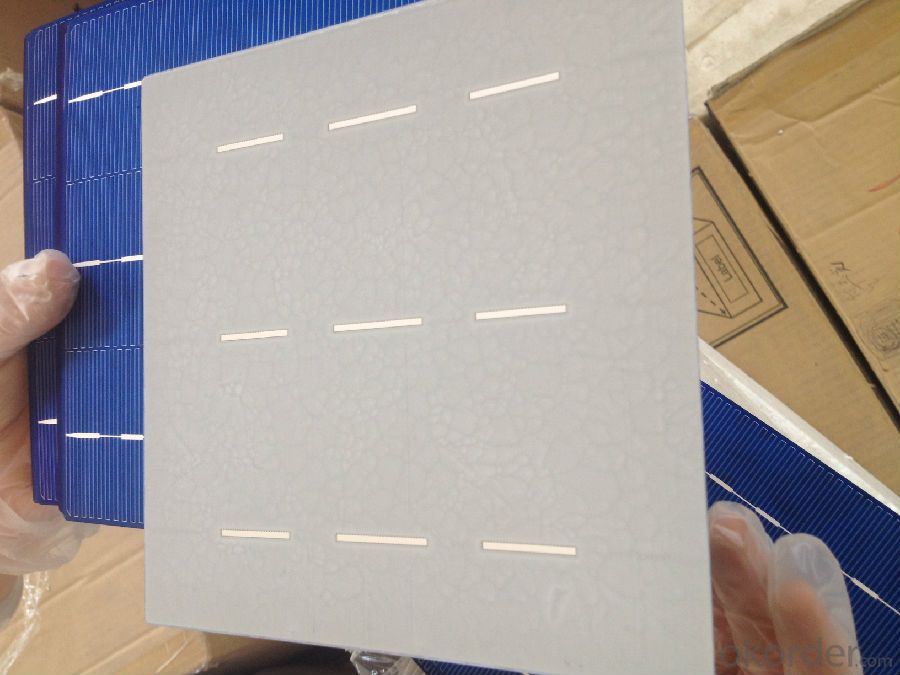

Solar Panel Images:

FAQ

We have organized several common questions for our clients,may help you sincerely:

①What price for each watt?

It depends on the efficiency of the solar cell, quantity, delivery date and payment terms.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③Can you provide the peripheral products of the solar panels, such as the battery, controller, and inverter? If so, can you tell me how do they match each other?

Yes, we can, we have two companies for solar region, one is CNBM International, the other is CNBM engineering Co.

We can provide you not only the solar module but also the off grid solar system, we can also provide you service with on grid plant.

④What is your warranty of solar cell?

Our product can promise lower than 0.3% open box crack, we support claim after opening the box if it has crackm color difference or sth, the buyer should give pictures immediately, we can not accept the claim after the solar cell has assembled to solar panel.

• Timeliness of delivery

• ⑤How do you pack your products?

We have rich experience on how to pack the solar cell to make sure the safety on shipment, we could use wooden box or pallet as buyer's preference.

⑥ Can you do OEM for us?

Yes, we can.

In today's energy shortage situation, countries have stepped up the pace of development of photovoltaic. United States proposed "solar pilot project" are intended to reduce the cost of solar photovoltaic power generation to 2015 levels of commercial competition; Japan also made a total power generation of PV reached 28GW in 2020. In the context of the development of low-carbon economy, governments’ acceptance of photovoltaic power generation increased gradually.

Applications of Solar Cell Huge:

1. Traffic areas, such as beacon lights, traffic / railway signal lamps, traffic warning / marker lamps, lights, altitude obstacle light, highway / railway wireless telephone booth, unattended Road class power supply.

2. Communication / communication field: Solar unattended microwave relay stations, cable maintenance stations, broadcasting / communication / paging power system; rural telephone carrier photovoltaic systems, small communication equipment, soldiers GPS power supply.

3. Petroleum, marine, meteorology areas: oil pipelines and reservoirs gate cathodic protection solar power systems, oil drilling platform life and emergency power supply, marine testing equipment, meteorological / hydrological observation equipment.

4. Household lighting power supply: such as garden lights, street lamps, portable lamps, camping lamps, light hiking, fishing lamp, black light, tapping lights, energy saving lamps.

5. The PV power plant: 10KW-50MW independent photovoltaic power plants, scenery (CHAI) complementary power plants, various large parking with charging stations.

6. Solar building solar power and building materials, renders the future of large buildings to achieve electricity self-sufficiency is a major development direction of the future.

7. Other areas include: (1) supporting the car: solar car / electric vehicle battery charging equipment, automobile air conditioners, ventilation fans, cold boxes, and so on; (2) solar hydrogen fuel cell power generation system of regeneration; (3) seawater desalination equipment supply; (4) satellite, spacecraft, space solar power stations.

- Q:How do solar cells contribute to reducing carbon emissions?

- Solar cells contribute to reducing carbon emissions by converting sunlight into electricity without burning fossil fuels. As a clean and renewable energy source, solar cells help decrease the reliance on coal, oil, and gas power plants that emit greenhouse gases. By harnessing the sun's energy, they generate electricity with zero carbon emissions, thereby mitigating climate change and promoting a more sustainable future.

- Q:Are solar cells affected by temperature?

- Yes, solar cells are affected by temperature. High temperatures can cause a decrease in the efficiency of solar cells, resulting in a reduction in their power output. However, modern solar cell technologies have been developed to minimize the impact of temperature on their performance.

- Q:How are solar cells made?

- Solar cells are typically made using a process called photovoltaic (PV) technology, which involves the assembly of semiconductor materials, usually silicon, into thin layers. The silicon is purified and then shaped into wafers, which are then treated with various dopants to create the desired electrical properties. Metal contacts are added to these wafers, and the cells are encapsulated with protective materials. When sunlight hits the cell, the photons from the sunlight create an electric field across the layers, generating electricity.

- Q:Can solar cells be used in healthcare facilities?

- Yes, solar cells can be used in healthcare facilities. They can be employed to generate electricity, which can power medical equipment, lighting, and other essential systems in healthcare facilities. Solar energy can help reduce reliance on the conventional power grid, providing a sustainable and cost-effective source of electricity for healthcare facilities, especially in remote or off-grid areas. Additionally, solar cells can contribute to reducing carbon emissions and promoting environmental sustainability in the healthcare sector.

- Q:What is the environmental impact of solar cells?

- The environmental impact of solar cells is generally positive. They produce clean and renewable energy, reducing greenhouse gas emissions and dependence on fossil fuels. However, their production does require some raw materials and energy, which can have environmental consequences. Additionally, the disposal of older solar panels may pose challenges in terms of electronic waste management. Overall, though, the benefits of solar cells outweigh their environmental drawbacks.

- Q:How can the solar power change our life by using solar cells material?

- Solar power is at least 1/3 less expensive than coal-fired power . How can not the solar energy be used to change our life?

- Q:What is the best way to deal with surplus solar cells abandoned after burning?

- The surplus of solar cells can be very useful or useless at all. Totally depend on how people try to apply it to the new construction work.

- Q:Can solar cells be used on wearable technology?

- Yes, solar cells can be used on wearable technology. Advances in technology have made it possible to integrate solar cells into small and flexible materials, making them suitable for use in wearable devices. These solar cells can generate and store energy from sunlight, allowing wearable technology to become self-sustaining and reducing the need for frequent recharging or battery replacements.

- Q:Can solar cells be used for aerospace applications?

- Yes, solar cells can be used for aerospace applications. They are commonly used in satellites and spacecraft to generate electrical power from sunlight. Solar cells are lightweight, reliable, and efficient, making them ideal for powering various systems and instruments in space missions.

- Q:Can solar cells be used for powering remote data collection devices?

- Yes, solar cells can be effectively used for powering remote data collection devices. Solar cells convert sunlight into electricity, providing a sustainable and reliable source of power in areas where access to conventional electricity may be limited or non-existent. By harnessing solar energy, remote data collection devices can operate autonomously without the need for frequent battery replacements or external power sources, making them ideal for applications such as weather monitoring stations, wildlife tracking devices, or environmental sensors in remote locations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

China Polycrystalline Solar Cells With High Quality and Stable Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 PCS

- Supply Capability:

- 8000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords