BASF Glue Coated Marble Backing Mesh, 56g/m2

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

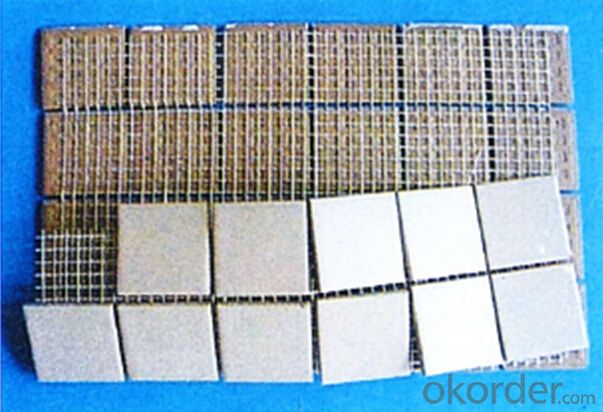

Quick Details of BASF Glue Coated Marble Backing Mesh, 56g/m2

FOB Price of BASF Glue Coated Marble Backing Mesh, 56g/m2 US $0.198 / Square Meter

MOQ of BASF Glue Coated Marble Backing Mesh, 56g/m2: 10000 Square Meters

Supply Ability of BASF Glue Coated Marble Backing Mesh, 56g/m2: 6000000 Square Meters per Month

Payment Terms of BASF Glue Coated Marble Backing Mesh, 56g/m2: L/C,T/T

BASF Glue Coated Marble Backing Mesh, 56g/m2

Specifications of BASF Glue Coated Marble Backing Mesh, 56g/m2

BASF Glue Coated Marble Backing Mesh, 56g/m2 Place of Origin: China (Mainland)

BASF Glue Coated Marble Backing Mesh, 56g/m2 Brand Name: CMAX

BASF Glue Coated Marble Backing Mesh, 56g/m2 Application: Wall Materials

BASF Glue Coated Marble Backing Mesh, 56g/m2 Width: 1M-2M

BASF Glue Coated Marble Backing Mesh, 56g/m2 Size: 5*5/ INCH

BASF Glue Coated Marble Backing Mesh, 56g/m2 Weight: 40gsm to 200gsm

BASF Glue Coated Marble Backing Mesh, 56g/m2 Weave Type: Plain Woven

BASF Glue Coated Marble Backing Mesh, 56g/m2 Yarn Type: C-Glass

BASF Glue Coated Marble Backing Mesh, 56g/m2 Alkali Content: Medium

BASF Glue Coated Marble Backing Mesh, 56g/m2 Standing Temperature: 500℃

Product information of BASF Glue Coated Marble Backing Mesh, 56g/m2

Name: BASF Glue Coated Marble Backing Mesh, 56g/m2

Use best fiberglass yarn and best glue

Clear and beautiful BASF Glue Coated Marble Backing Mesh, 56g/m2

High strength BASF Glue Coated Marble Backing Mesh, 56g/m2

30 years experience of manufacturing BASF Glue Coated Marble Backing Mesh, 56g/m2

Excellent Priced BASF Glue Coated Marble Backing Mesh, 56g/m2

FAQ of BASF Glue Coated Marble Backing Mesh, 56g/m2

Q: What is BASF Glue Coated Marble Backing Mesh, 56g/m2?

Coated Alkali-resistant BASF Glue Coated Marble Backing Mesh, 56g/m2 is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of BASF Glue Coated Marble Backing Mesh, 56g/m2?

Weight: 135g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of BASF Glue Coated Marble Backing Mesh, 56g/m2?

Marble slab reinforcement / Mosaic carrier

Q: What is the storage of BASF Glue Coated Marble Backing Mesh, 56g/m2?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of BASF Glue Coated Marble Backing Mesh, 56g/m2?

Four years under normal weather conditions and use .

Q: What is the package of BASF Glue Coated Marble Backing Mesh, 56g/m2?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of BASF Glue Coated Marble Backing Mesh, 56g/m2?

Production periods: 30days for 1X40HQ.

- Q:Why does the construction sector have no supervision on the use of fiberglass mesh?

- External thermal insulation needs a large amount of fiberglass mesh.

- Q:What is the function of interior design mesh?

- Its raw material is medium alkaline or non-alkaline glass fiber yarn. Modern buildings are made from concrete or bricks. The features like crack resistance can be restored. This is lightweight wall.

- Q:Why is it required to be under 5℃ while paving carbon fiber mesh?

- Hang horizontal line in suitable palces on each floor. Specially-assigned person is responsible for compounding special adhesive. Fastener installation should be held at least 24 hours later, finishing pasting board. The length of the fixed plate is 50mm-thickness. Plastering polymer mortar and binding agent should be instant. 5mm-1mm surface layer of mortar, depending on the fixture aperture diameter, depending on the plate surface polished, non-standard size or a continuation is at field-crop, internal and external corners must be lapped ony by one to strengthen the role of the defense, playing the line of control. Because of its excellent acid resistance, it won't crack though subjected to all sorts of changes in stress without cracking, since the glass fiber mesh obedient.

- Q:Should the wall that has been covered by the wallpaper be pasted with Mesh?

- The price is not high, so you can paste if you like. It can make it more easy if you want to change latex in future.

- Q:How to increase the glass fiber net fabric tensile strength

- The strength can be improved after rigid fixation, fracture test of transverse tension retention rate is a good way to a quality evaluation, but not necessarily apply to your products, manufacturers recommend looking for appropriate adjustments according to the characteristics of the product to you.

- Q:Why is it required to wrap alkali-resistant fiberglass mesh at the entrance to the hole?

- Flanging is good for protecting the edge of insulating layer and door and window are vulnerable to external damage. The window and door openings and other locations are not the continuation of the mesh position, large wall decapitated need Internet Plaid lap, discrete locations Mesh prone to stress concentration cracks,

- Q:Is the interior wall made of fiberglass mesh or wire mesh?

- If only partial cracks, can also use ordinary adhesive bandage. But in any case, when the wall putty is used, the steel wire mesh is not used, and if it is made of cement mortar, then the steel wire mesh should be used.

- Q:What is the base material of fiberglass mesh?

- Of course, its base material is glass fiber. You said it was rough, probably the reason wass that in the process of producing glass fiber, immature technology caused broken filament, and after treatment, the adhesive?sticker, alkali-resistant glue or weather-proof glue was unevenly attached on the surface. So it looks rough. This is just the unqualified product in production process, and there isn't any counterfeit product. These product are not beautiful and their strength will be lower than that of qualified products. (The intensity of different mesh will have different degrees of decline: generally, the largest mesh opening is, the greater will the strength decline; conversely, the smaller mesh opening is, the smaller will the strength decline).

- Q:How to straighten the glass fiber gridding cloth?

- It is not recommended to trowel with mortar plastering. The softness of product can be controlled. However, the gridding is not easy to control with good positioning. The lower the hardness is, the worse positioning is. The hardness of product is related to the raw material. Therefore, the hardness should be proper. On the basis of good positioning, the Jingguo products should be coated with emulsion. The hardness may also affect the overall effect of the thermal insulation and construction. But when coating the emulsion, the wire will move with big tension. The products with different hardness have different positioning. When troweling with mortar, the product may be positioned. The hardness is also related to the glue coated on the surface. The hardness is controversial to the positioning.

- Q:what's the executive standard of alkali resistant mesh? What is the test method?

- JGJ144-2004 is external wall thermal insulation. Technical Specification GB20102-2006-T glass fiber mesh alkali resistance test method for sodium hydroxide solution soaking?method.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BASF Glue Coated Marble Backing Mesh, 56g/m2

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords