Aluzinc and Galvanized steel sheet in coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Galvalume should not be used on, in, or around concrete or mortar. Concrete and mortar are highly alkaline environments. Bare Galvalume and painted Galvalume sheets suffer rapid corrosion when in contact with mortar and concrete. Bare Galvanized and painted Galvanized perform better in this type of environment.

While Galvalume has excellent durability in many settings, it should not be used adjacent to concrete or mortar.

Due to the high alkaline content in these environments, bare and painted Galvalume rapidly corrode.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Packaging & Shipping

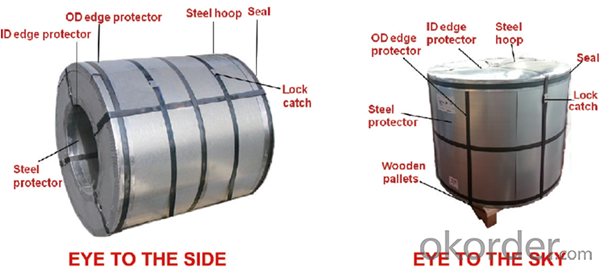

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q:i have a guitar with three nylon three steel strings. Am i able to replace the nylons with steel strings?

- DO NOT PUT ACOUSTIC (steel) STRINGS ON A CLASSICAL GUITAR. Classical guitars are not built to withstand the tension of steel strings. putting steel strings on a classical guitar can cause irreparable damage to the neck, where the neck joins the body and the heel. Classical guitars have nylon strings. Yes 3 of them look like steel strings, but these are actually metal wrapped around a nylon core. Acoustic guitars are metal strings. The wound strings on an acoustic have a metal string core. Classical guitars tend to have a wider neck and are more for classical music, flamenco, finger picking, etc. Acoustic guitars can have lower tension strings put on them (e.g. martin silk and steel) as the guitar can be adjusted to take the lighter string tension placed on the neck and heel. Martin Silk and Steel Strings can also be put on a classical guitar as they have a lot lower tension than steel and they give a louder more acoustic sound.

- Q:What are the benefits of using steel coils in the manufacturing of pipes?

- There are several benefits of using steel coils in the manufacturing of pipes: 1. Strength and durability: Steel is known for its strength and durability, making it an ideal material for pipes. Steel coils provide a strong foundation for pipes, ensuring they can withstand high-pressure applications and resist damage from external factors such as impact or corrosion. This strength and durability enhance the longevity of the pipes, reducing the need for frequent replacements. 2. Flexibility: Steel coils offer flexibility in terms of customization and design. They can be easily formed into various pipe shapes and sizes, allowing manufacturers to produce pipes that meet specific project requirements. This flexibility also enables the production of seamless pipes, which have superior structural integrity and reduced risk of leakage. 3. Thermal resistance: Steel has excellent thermal conductivity, meaning it can efficiently transfer heat or cold. This property is crucial for pipes used in industries such as oil and gas, where temperature control is essential. Steel coils enable the manufacturing of pipes that can effectively handle extreme temperatures, preventing any damage to the pipes or the substances flowing through them. 4. Cost-effectiveness: Steel coils can be produced in large quantities, resulting in economies of scale and lower production costs. This cost-effectiveness is beneficial for both manufacturers and consumers, as it helps keep the overall cost of pipes down. Additionally, the durability of steel pipes reduces the need for frequent repairs or replacements, saving money in the long run. 5. Corrosion resistance: Steel coils can be coated with protective layers to enhance their resistance to corrosion. This corrosion resistance is crucial in applications where pipes come into contact with corrosive substances or are exposed to harsh environmental conditions. By using steel coils with appropriate coatings, manufacturers can ensure that their pipes have a longer lifespan and maintain their structural integrity under challenging circumstances. Overall, the use of steel coils in pipe manufacturing offers numerous advantages, including strength, flexibility, thermal resistance, cost-effectiveness, and corrosion resistance. These benefits make steel coils a preferred choice for many industries that rely on durable and efficient piping systems.

- Q:Having a new kitchen and would like to know the pros and cons of stainless steel as opposed to white appliances. I can only think of finger marks on the SS, which I believe are difficult to remove. Anyone had both that they could advise please?

- Like others said about Stainless Steel, plus if bleach accidentally touched it, it will leave a permanent scar, Stainless Steel can be cleaned with water and soap then with baby oil. White will be better.

- Q:How are steel coils used in the manufacturing of food packaging?

- Steel coils are commonly used in the manufacturing of food packaging as they are shaped and formed into cans, containers, and lids, providing a strong and durable material for ensuring the safety and preservation of food products.

- Q:How are steel coils inspected for bendability using bend testers?

- Bend testers are specialized machines utilized to inspect the bendability of steel coils, measuring their flexibility and resistance against bending. The inspection process involves multiple steps to guarantee precise and dependable outcomes. To begin with, the steel coil is prepared by securing it firmly in place, typically using clamps or other mechanisms to prevent any movement during testing. This ensures stability and enables consistent and repeatable measurements. Following that, the bend tester is set up according to the specified testing parameters. These parameters usually include the desired bend angle, the speed at which the bend is applied, and the number of cycles to be performed. The bend tester is equipped with a bending mechanism that applies a controlled force on the coil, simulating the bending conditions it may experience in its application or use. Once the bend tester is ready, the bending process commences. The machine gradually applies an increasing force to the steel coil until it reaches the desired bend angle. Careful measurement and monitoring of this force take place throughout the process to ensure accuracy. While the bending process is underway, the machine records and displays significant data, such as the applied force, the angle of bend, and any indications of cracking or other defects. This data is crucial for evaluating the bendability of the steel coil and determining its compliance with required standards. Once the desired bend angle is attained, the coil is released from the bending mechanism, allowing any residual stresses to relax. This relaxation period is essential for observing any potential spring-back effect, where the coil partially returns to its original shape after bending. The amount of spring-back is also measured and recorded for further analysis. Finally, the inspection results are analyzed to assess the overall bendability of the steel coil. If the coil meets the specified bendability criteria, it can be deemed acceptable for its intended application. However, if any cracks, fractures, or excessive spring-back are detected, further investigation and analysis may be necessary to identify the cause and determine appropriate corrective actions. In conclusion, bend testers play a crucial role in inspecting the bendability of steel coils. Through a controlled and systematic process, these machines accurately measure flexibility and resistance to bending, ensuring the quality and reliability of steel coils used in various industries.

- Q:What material is strongest? Human bone, steel, or concrete?

- Steel is used to shape and reinforce concrete. Steel is also used in cutting bones in surgery and repairing bone through use of steel pins and braces. So, the answer is most definitely steel. In answer to your watch question, the volume of concrete was greater than that of your watch. The question of large volume vs. small volume is an easy one. Ten tons of human bone would easily reduce a 1 lb block of concrete to powder. Likewise, ten tons of concrete would snap a steel bar like a toothpick. Your watch had much less volume than the concrete you dropped it on. Furthermore, with enough force, your watch would have made a hole in the concrete, but its acceleration was not enough to counter the impacting force of the solid concrete reinforced by the soil and clay below it.

- Q:Ok, I have motorcycle classes and im afraid that I wont feel the gear shifter when shifting. So I want to make the boot softer from the toes where the steel is at so i can feel the gear shift with my toes. When i walk and bump into something by accident with my boots I dont feel anything I almost dont notice it. So I think i will be a problem since I wont be able to feel anything.

- You're not from this world, are you?

- Q:How are steel coils packaged for shipping?

- Steel coils are typically packaged for shipping by placing them on wooden or steel pallets, securing them with steel bands or straps, and covering them with protective wrapping such as plastic or waterproof paper. This packaging ensures the coils remain stable, protected from corrosion, and are easy to handle and transport.

- Q:Have spent two days making a specialized knife out of 304 stainless steel, after throwing into a log it bent slightly arghhhh. Is it worth continuing to finish it off or start all over again with different kind of steel if so which kind should i use.

- Sorry okorder /... I hope that link works but as you can see you dont want to use 303.304.316,410,416,430 You can get away with 301 but would be best to use 440. It kind of sounds like your a home shop guy. It would be best for you to make a knife out of a1 or d2 tool steel. with these steels you can torch heat them to a red hot heat where a magnet will not stick to them. Then let them cool slowly in the air. After that you can temper in a oven around 400f. This will a very hard long lasting knife. Check OKorder for good steel prices. A1 and D2 are not stainless but they are the best for a home shop. If you go stainless you can buy preharden material but you will have to grind everything. You can also pay someone to harden your knife but dont plan on it being cheap.

- Q:Are steel coils used in electrical equipment manufacturing?

- Yes, steel coils are commonly used in electrical equipment manufacturing. They are often used in the construction of transformers, motors, generators, and other electrical devices. The steel coils provide structural support, magnetic properties, and efficient conduction of electricity, making them an essential component in electrical equipment manufacturing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluzinc and Galvanized steel sheet in coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords