Aluminium Remelting Coil Like Aluminium Ingot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

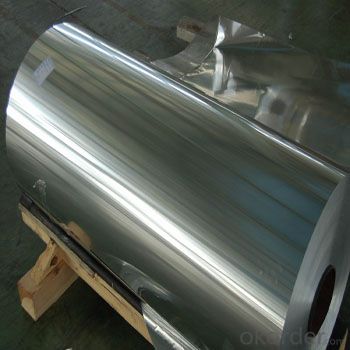

ALUMINIUM FOIL

ALLOY:AA1***

TEMPER: F O H14 H16 H18 H22 H24 H26

THICKNESS: 0.006MM-0.20MM

WIDTH: 200MM-1600MM

COATING: HSL/PRIMER

STANDAR: GB/T 3198-2003

2.Application

Our Remelting aluminium coil is the same as aluminium ingot, and the price is cheaper.

3.Why you can truct us?

We promise the best quality and price!

4.Pictures

5.FAQ

1)what is aluminum?

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

2)What's kind of payment term we can supply?

CIF,CFR, FOB and other.

3)Can we supply samples?

Yes, we can!

4)What can you do if you have other quastions?

You can contact us freely at any time!

- Q:Can aluminum coils be used in wastewater treatment plants?

- Yes, aluminum coils can be used in wastewater treatment plants. Aluminum coils are commonly used in the construction of heat exchangers, which are essential components in wastewater treatment plants. Heat exchangers are used to transfer heat from the wastewater to the treatment process, helping to optimize the treatment efficiency and reduce energy consumption. Aluminum coils are preferred in some cases due to their excellent thermal conductivity, lightweight, and resistance to corrosion, making them suitable for the harsh environment of wastewater treatment plants. Additionally, aluminum coils are cost-effective and have a long lifespan, making them a reliable choice for use in wastewater treatment facilities.

- Q:When you open an aluminum beverage can, do particles of aluminum get into the drink?

- It depends on the type of drink inside the can. Aluminium is a metal in the group three of the periodic table of elements so it has three positive charges when ionized although it has metallic bond between its nucleus and its electrons. If the drink contains too much acid such as HCl with a high concentration the acid may react with the aluminium can if it is not coated or galvanized. Although it may not physically break off for the particles to enter the drink, it may dissolute in the kind of substance inside the drink.

- Q:What are the different types of surface finishes for decorative purposes?

- There are several types of surface finishes for decorative purposes, including glossy, matte, textured, metallic, and antique finishes.

- Q:What are the common maintenance practices for aluminum coils?

- Some common maintenance practices for aluminum coils include regular cleaning, inspection for damage or corrosion, and ensuring proper airflow around the coils. Cleaning the coils is important to remove dirt, debris, and other contaminants that can accumulate over time. This can be done by gently brushing or vacuuming the coils, or using a mild detergent and water solution to clean more stubborn dirt. It is important to avoid using harsh chemicals or abrasive materials, as they can damage the aluminum surface. Inspecting the coils for damage or corrosion is also essential for maintaining their performance and longevity. Any signs of physical damage, such as dents or bends, should be addressed promptly to prevent further deterioration. Additionally, corrosion can occur due to exposure to moisture or chemicals, so it is important to check for any signs of rust or discoloration. If corrosion is present, it should be treated and the cause of the corrosion should be addressed to prevent future damage. Proper airflow around the coils is crucial for efficient operation. Obstructions or blockages in the surrounding area should be cleared to ensure adequate air circulation. This can include removing any debris or objects that may be restricting airflow, as well as ensuring proper spacing between the coils and nearby objects. Additionally, regular inspection of the air filters and ventilation system is important to prevent any restrictions that could impact airflow. Overall, regular cleaning, inspection, and maintenance of aluminum coils can help ensure their optimal performance and prolong their lifespan. It is recommended to follow manufacturer guidelines and consult with professionals if any issues or concerns arise.

- Q:0.6mm insulation aluminum coil price insulation aluminum coil where to buy the most assured?

- Best site inspection, and now more factories, quality uneven

- Q:What are the different edge treatments available for aluminum coils?

- Some of the different edge treatments available for aluminum coils include mill finish, edge trim, deburred edge, rounded edge, and hemmed edge.

- Q:What can I get easily at Home Depot that will successfully bond rubber to aluminum?? I have tried several things with no success! Surely, there must be some sort of construction adhesive to do the job.Thanks!

- Gorilla Glue. I'd rough-up both the rubber and aluminum with course-grit sandpaper, or a wood-rasp first. Generally though, rubber is molded in place or fastened with a mechanical fastener (Screw, bolt, rivet, etc).

- Q:What are the common cutting and shaping methods for aluminum coils?

- Depending on the desired outcome and application, there are several cutting and shaping methods for aluminum coils. One of the most frequently used methods is shearing, which involves cutting the aluminum coil with a sharp blade. Shearing is suitable for straight cuts and is commonly employed in manufacturing automotive parts or construction materials that require precise dimensions. Slitting is another method that involves cutting the aluminum coil into narrower strips. Industries such as packaging often utilize slitting to create thin strips of aluminum for products like food packaging or aluminum foil. For more complex shapes like curves or bends, press brake forming is often employed. In this process, the aluminum coil is placed in a press brake machine and bent into the desired shape using a punch and die. Press brake forming is commonly used in industries like aerospace or architectural design, where intricate shapes are necessary. Additionally, laser cutting is a popular method for cutting aluminum coils. This method uses a high-powered laser beam to cut through the aluminum, allowing for precise and intricate cuts. Industries like signage or electronics often utilize laser cutting for creating detailed designs. In conclusion, the common cutting and shaping methods for aluminum coils include shearing, slitting, press brake forming, and laser cutting. These methods provide manufacturers with various options to shape aluminum coils according to their specific needs and requirements.

- Q:I have my brother's old wooden crutches but i see everyone using aluminum and i have the option to get aluminum ones. Is there any reason why they'd be better then my wooden ones?

- crutches are crutches!

- Q:My boyfriend sweats a lot and uses Mitchlum deodorant, a lot of it, under his armpits and waits til it dries to stop the sweating. I heard aluminium was bad for you, but he says natural deodorants don't work as well. What do you think?

- Aluminium is bad for you and too much aluminium can cause Alzheimer's disease and other problems. External deodorants are displaced by your perspiration and don't last long. Liquid chlorophyll is an internal deodorant that deodorises your body odours and perspiration odours before they come out of your pores. A table spoon of high strength liquid chlorophyll every day is all you need. Liquid chlorophyll also has a cooling effect so you perspire a bit less. You can find further information in a search for liquid chlorophyll + deodorant.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Remelting Coil Like Aluminium Ingot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords