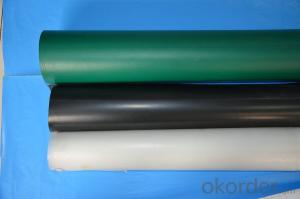

Xr-5 Geomembrane

Xr-5 Geomembrane Related Searches

Blu Ray Player With Internet Geomembrane In Pakistan 30 Mil Pvc Geomembrane Pvc Geomembrane Specifications Pvc Geomembrane Geomembrane Machine Plastic Geomembrane Nonwoven Wallpaper Geomembrane Material Geomembrane FabricHot Searches

Geomembrane For Sale China Pvc Geomembrane China Geomembrane Roll Sheet Hdpe Geomembrane Sheet Price Hdpe Geomembrane China China Geomembrane Geomembrane China Hdpe Geomembrane Price Geomembrane Price Wholesale Hdpe Geomembrane Roll Geomembrane Factory Wholesale Liner Hdpe Geomembrane Wholesale Geomembrane Hdpe Wholesale Hdpe Geomembrane Geomembrane Market Size Wholesale Hdpe Geomembrana Wholesale Liner Geomembrane Geomembrane Liner Supplier Wholesale Geomembrane China Pvc GeomembraneXr-5 Geomembrane Supplier & Manufacturer from China

Okorder.com is a professional Xr-5 Geomembrane supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Xr-5 Geomembrane firm in China.Hot Products

FAQ

- nan

- If it contains little carbon black, it will have poor UV resistance and aging resistance performance, so is the case when it contains too much. So it is not the higher the better. Usually the carbon black content is between 2% -3%. carbon black content can be adjusted by adding into geomembrane black masterbatch.

- nan

- 1 3920109010 agricultural non-foamed polyethylene thin film, 2 3920109090 other non-foamed ethylene polymer plates, sheets, film, foil and flat strip(non-agricultural).

- nan

- serial number item indicator common environmental protection 1 thickness mm 0.2 to 4 2 width m 2.5 to 8 3 tensile strength (vertically and horizontally) MPa≥17 ≥25 4 breaking elongation rate (vertically and horizontally) % ≥450 ≥550 5 angle tear strength N/mm ≥80 ≥110 6 carbon black content % 2.0 to 3.0 2.0 to 3.0 7 resistance to environment stress cracking F20 ≥1500 8 low-temperature impact in -70℃ approved 9 oxidative inductive time in 200℃ ≥20

- Geomembranes help in groundwater protection by acting as a barrier to prevent contaminants from infiltrating the groundwater. These synthetic liners are impermeable and can be used to line landfills, ponds, and other containment areas to prevent leakage of hazardous substances into the underlying groundwater. This helps in safeguarding the quality and availability of groundwater resources, which are crucial for drinking water supply and ecosystem health.

- Geomembranes perform well in high salinity environments due to their excellent chemical resistance properties. They are specifically designed to withstand exposure to various chemicals, including salts, making them highly effective in preventing leakage and contamination. The impermeable nature of geomembranes ensures that saltwater or other saline solutions do not penetrate through, maintaining the integrity of the containment system. Overall, geomembranes offer reliable performance and durability in high salinity environments.

- Municipal two cloth a film composite geomembrane quota how set

- Hello, this friend, should be the material construction costs, Henkel two cloth for your answer.

- Geomembranes contribute to the protection of buried pipelines by acting as a barrier that prevents the penetration of moisture, chemicals, and other harmful substances into the pipeline. This helps to prevent corrosion, degradation, and potential leaks, ensuring the long-term integrity and lifespan of the pipeline. Additionally, geomembranes also provide insulation against temperature fluctuations and ground movements, reducing the risk of damage to the pipeline.

- Preparation of composite geomembrane precautions?

- Composite geomembrane used to pay attention to matters: 1, the construction staff must wear non-staple or rubber shoes, to prohibit any trampling on the geomembrane. 2, after the film should be timely protective layer construction, to prevent heat shrinkage caused by geomembrane deformation and ultraviolet radiation caused by geomembrane aging. 3, prohibit contact with polyolefins can cause changes in chemical properties, so as not to permanent deformation of geomembrane. 4, the machine must not directly crush the geomembrane surface.